Ethyl thioctic acid salt hot hydrolyzate cooling apparatus

A technology of ethyl lipoic acid and cooling equipment, which is applied in the direction of heat exchanger types, indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of long cooling time and production efficiency constraints, and achieve the improvement of reaction cooling speed and improvement The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

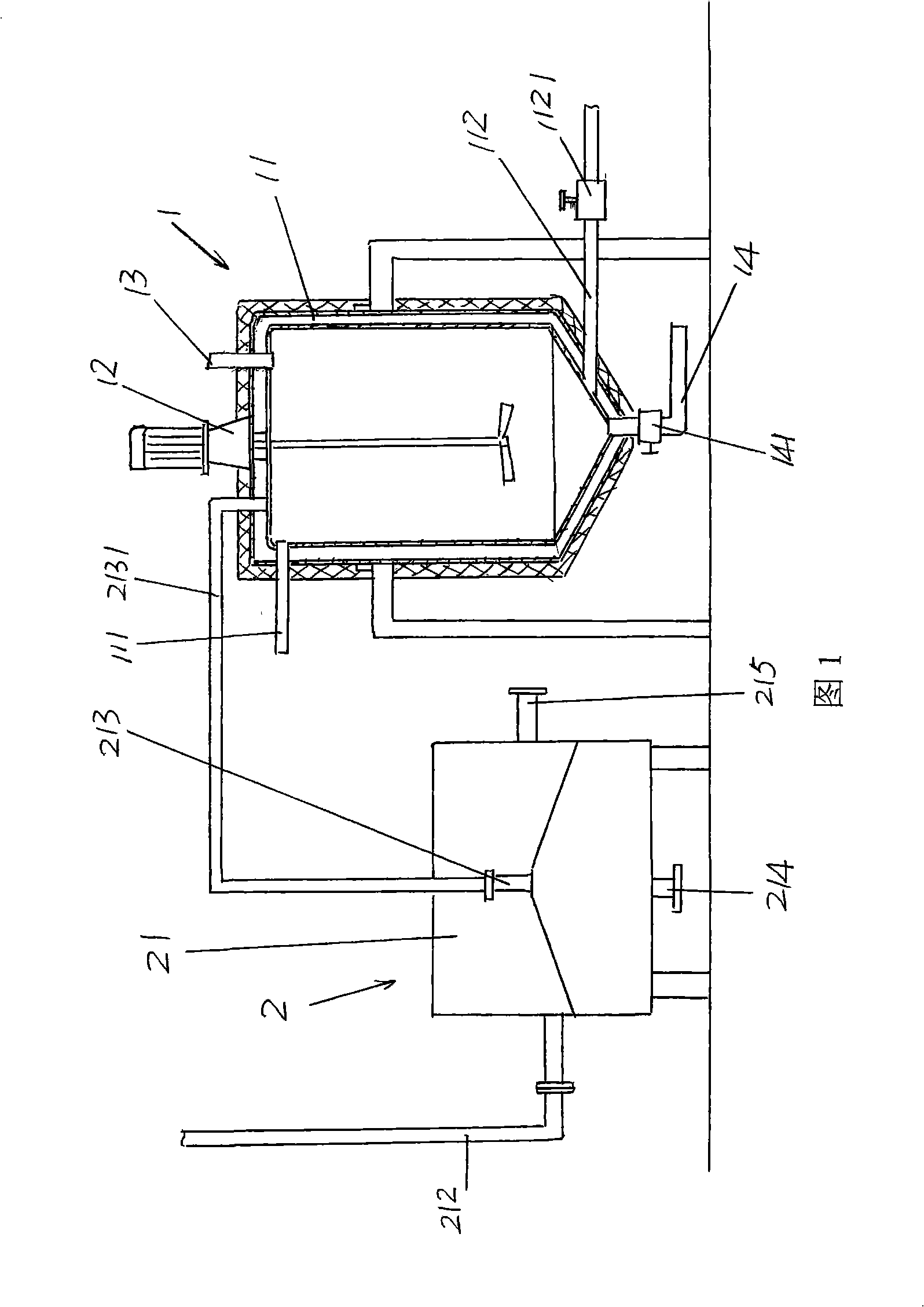

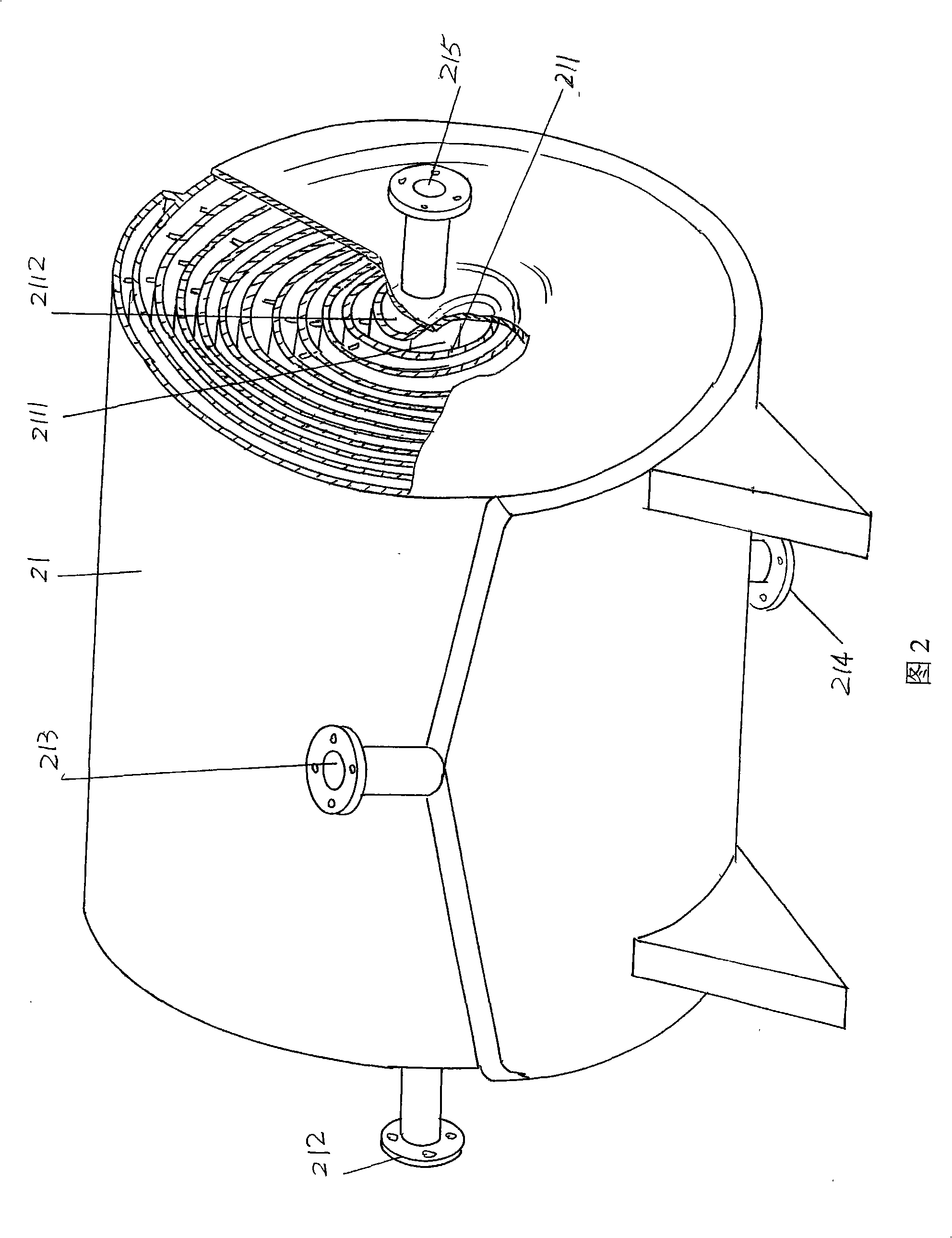

[0012] See also Fig. 1 and Fig. 2, have provided the known common reactor 1 in the prior art, this reactor 1 is equipped with agitator 12 and is formed with jacket 11, and the side upper part of jacket 11 is extended and is used for introducing A refrigerant inlet port 111 for the refrigerant is provided, and a refrigerant outlet port 112 for leading out the refrigerant is extended to the lower side of the jacket 11 . The feed inlet at the top of the reactor 1 is connected with the pipeline 2131 of the precooling mechanism 2 described in detail below, so that the lipoic acid ethyl ester thermal hydrolyzate after the precooling mechanism 2 is precooled by the pipeline 2131 is introduced into the In the still body (in the still cavity) of the reaction kettle 1, the thermal hydrolysis solution of ethyl lipoic acid in the kettle body is cooled by the aforementioned refrigerant. Introduce the acidification liquid to carry out the acidification reaction. After the acidification reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com