Method for detecting temperature field uniformity of ceramic brick kiln

A detection method and technology of ceramic tiles, applied to parts of thermometers, thermometers based on material expansion/contraction, thermometers, etc., can solve the problems of low pass rate, time-consuming and labor-intensive, low production efficiency, etc., to improve production efficiency, The operation method is simple and easy to understand, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

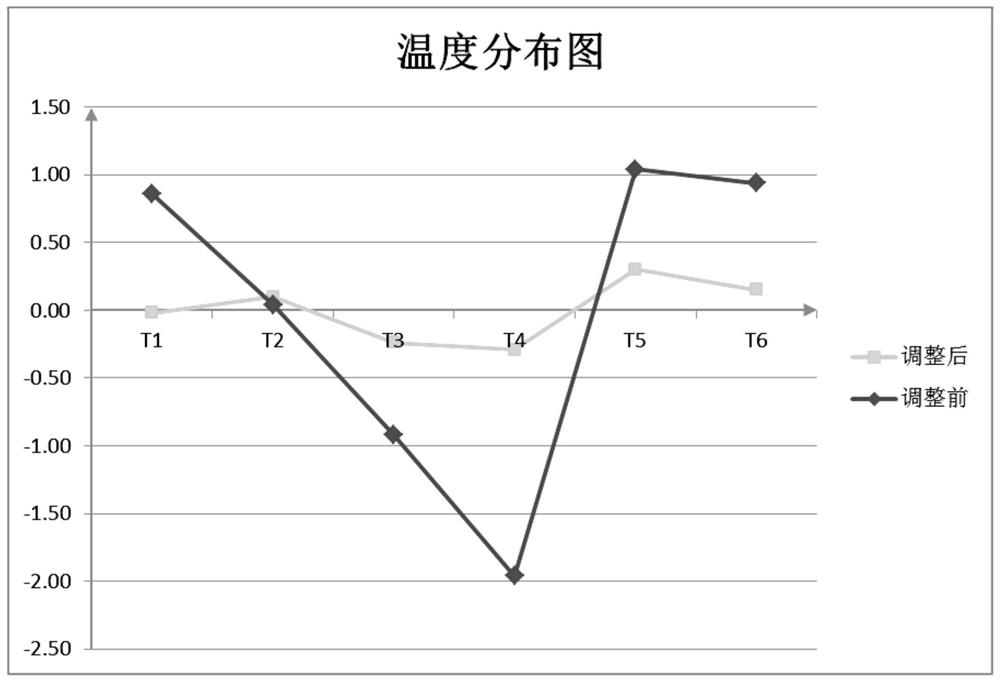

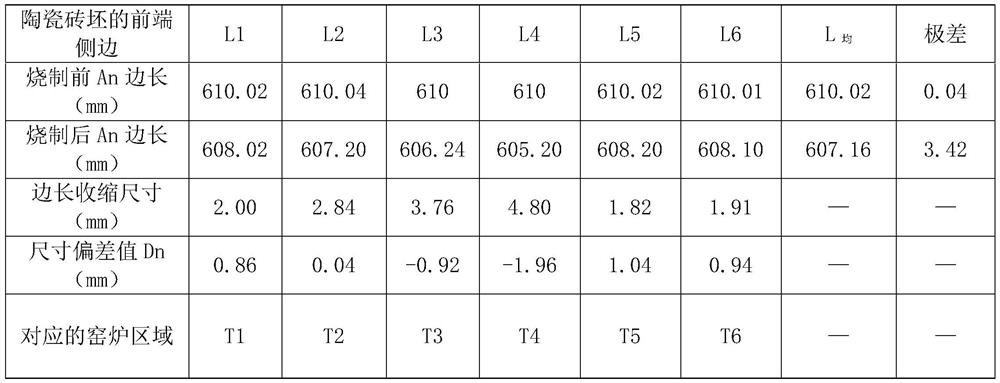

[0062] Before batch production of 600×600 ceramic tiles, check the temperature distribution uniformity of the cross-section perpendicular to the running direction of the ceramic tile kiln, and adjust the temperature distribution of the ceramic tile kiln to ensure the quality of ceramic tiles produced in batches The side length meets the quality control target of the range ≤ 1.0mm after firing. The specific steps are as follows:

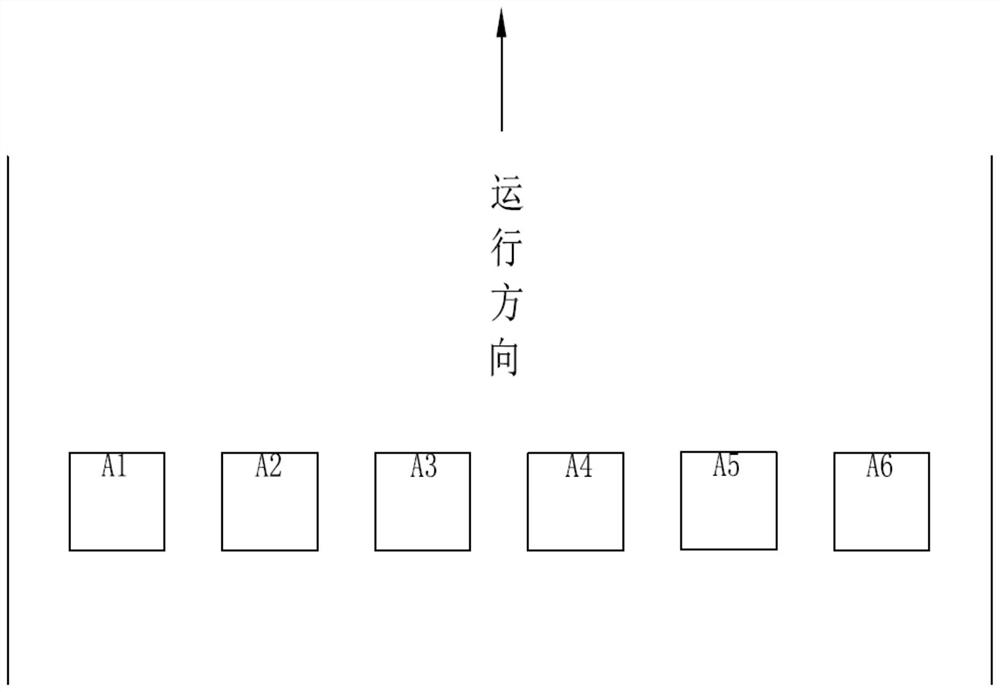

[0063] 1. The width of the ceramic brick kiln to be tested is about 3.8m, and the heating channel is equidistantly divided into six areas of T1, T2, T3, T4, T5 and T6 with a width of about 0.633 meters along the running direction; select For six 600×600 ceramic tiles pressed in the same mold cavity, set the front sides of the six ceramic tiles in the direction of ejection as sides A1, A2, A3, A4, A5 and A6, and place the six ceramic tiles, etc. (the spacing is about 28mm) and placed in the T1, T2, T3, T4, T5 and T6 areas of the ceramic brick kiln, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com