Method for detecting blank filling uniformity of ceramic tile green body

A ceramic brick adobe and detection method technology, which is applied in the field of ceramic brick production, can solve problems such as large differences in filling uniformity, poor efficiency, and heavy workload, and achieve simple and easy operation methods, improve filling uniformity, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

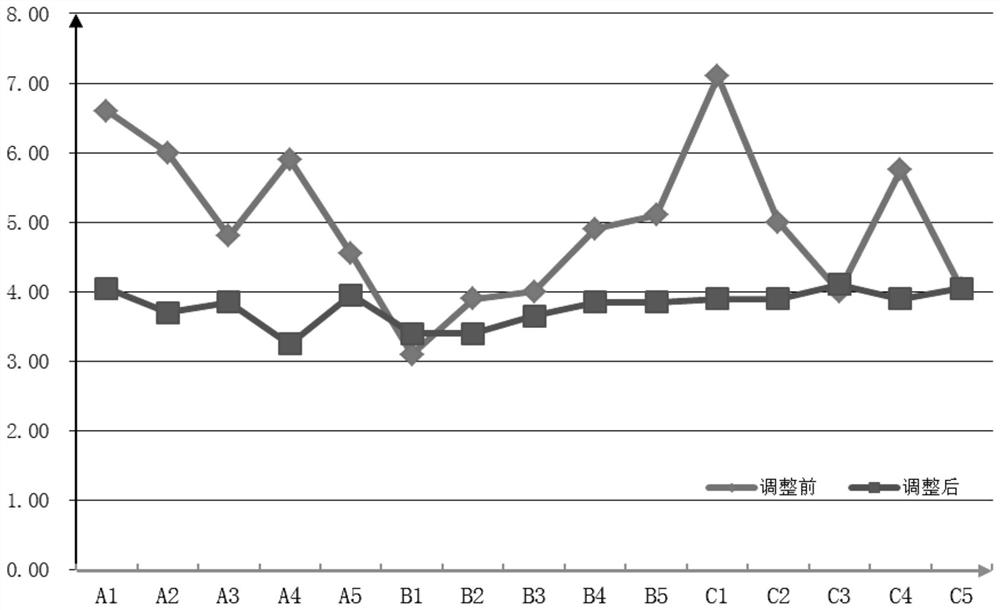

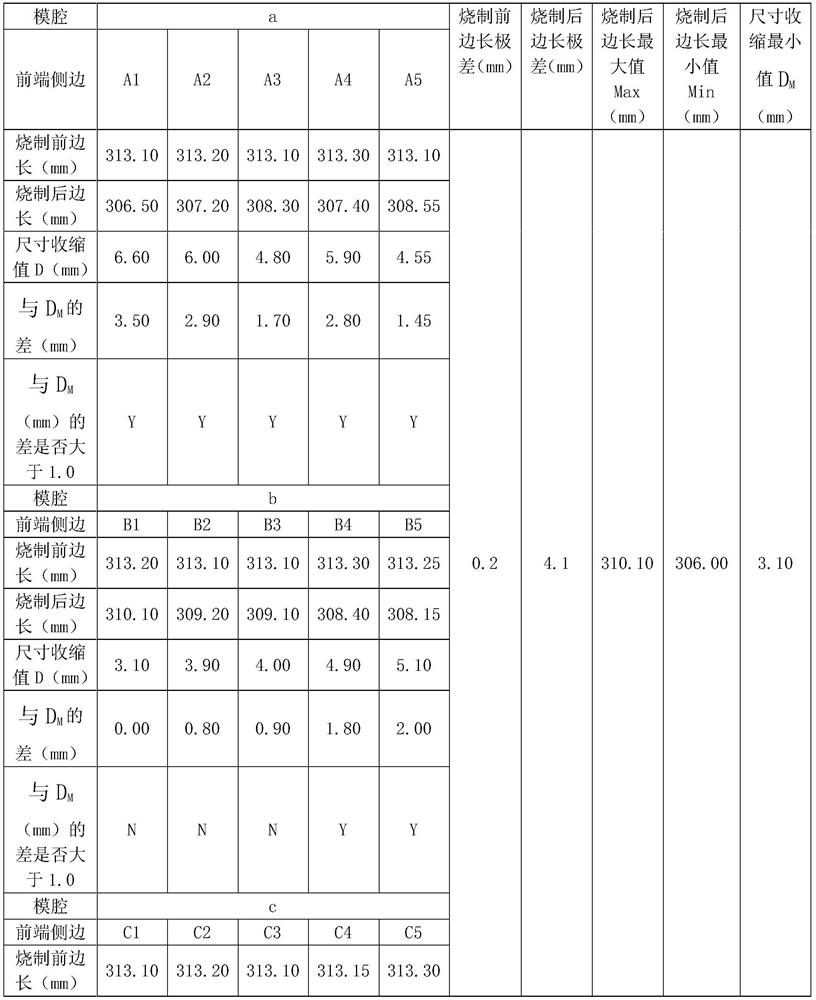

[0075] Before mass production of 300×300 ceramic tiles, inspect and adjust the filling uniformity of the ceramic tiles, set the side length range of the ceramic tiles to be ≤1.0mm, the detection object is the length, and the mold cavity is a square. The specific steps are as follows :

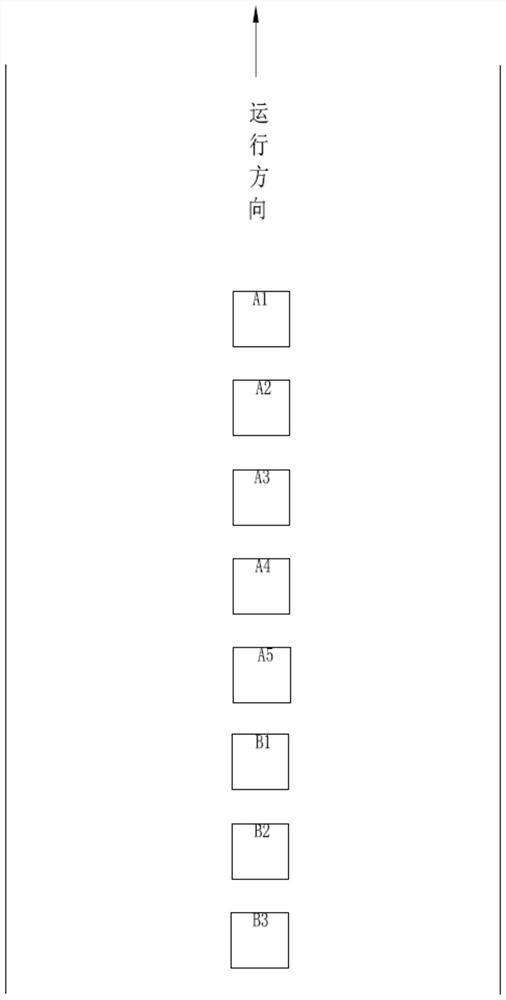

[0076] 1. Among a batch of ceramic tiles pressed by a mold containing three mold cavities a, b, and c, select five ceramic tiles of each of the three mold cavities a, b, and c, and set five pieces of a mold cavity The front-end sides of the ceramic tiles toward the front of the ejection direction are A1-A5 sides, and the front-end sides of the five ceramic tiles of the cavity b are set to be the B1-B5 sides toward the front of the ejection direction, and the sides of the cavity c are set. The front-end sides of the five ceramic bricks towards the front of the mold release direction are C1-C5 sides, and these ceramic bricks are arranged longitudinally and equidistantly in the ceramic brick kiln....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com