Elastic hanging device for journal sticking installation motor

A technology of elastic suspension and shaft installation, which is applied in the direction of transmission device driven by electric motor, elastic coupling, coupling, etc., to achieve the effect of saving structural space, reducing unsprung mass and strong displacement ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

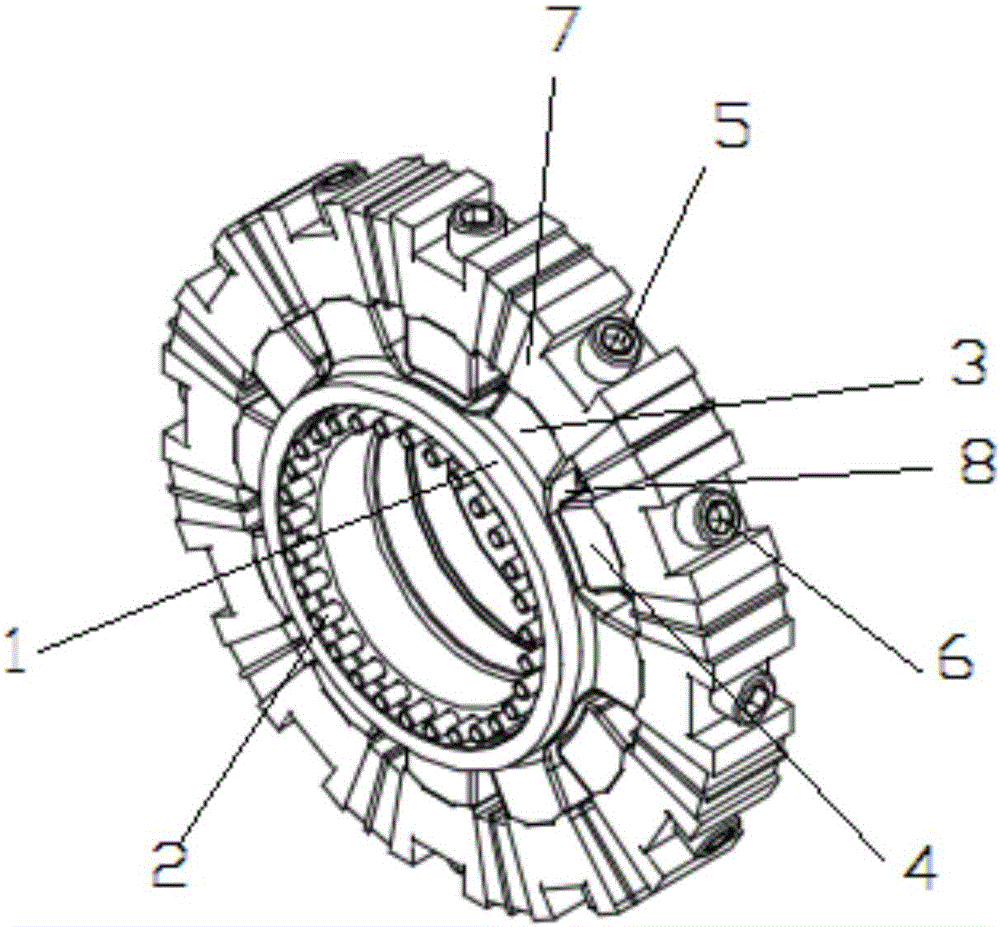

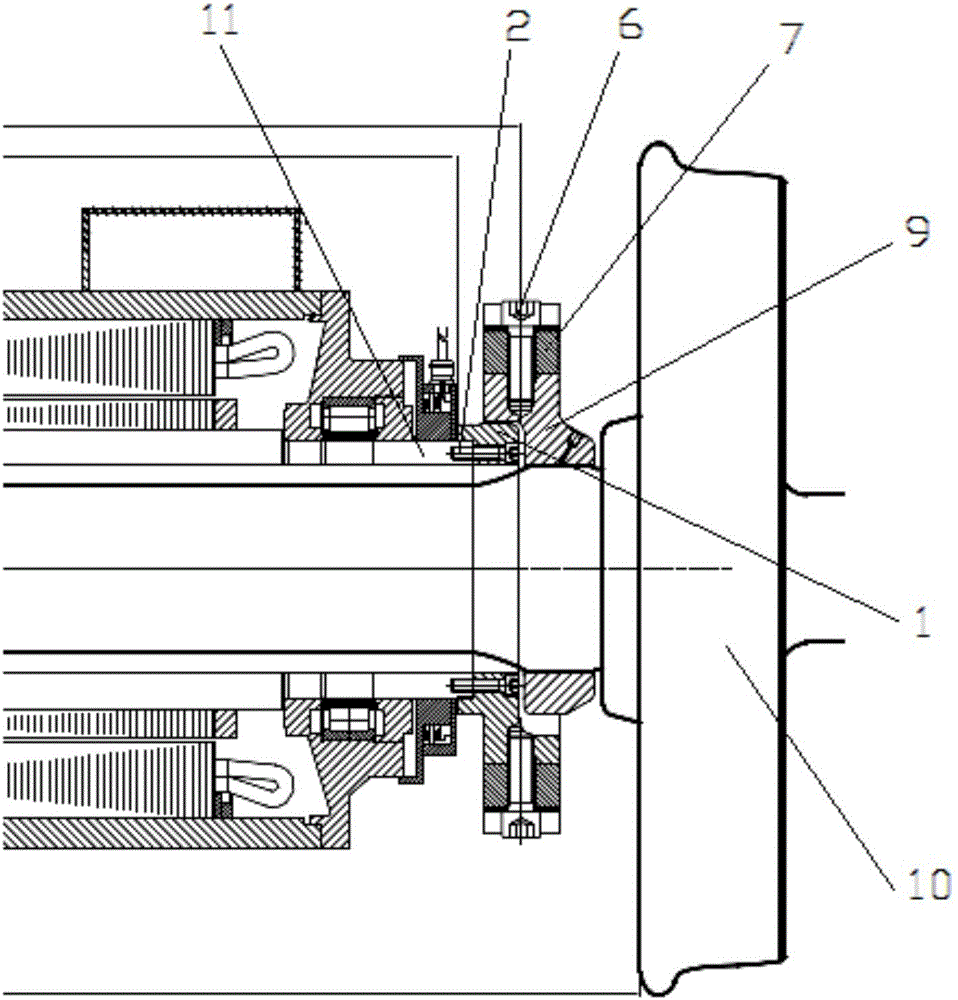

[0016] Such as figure 1 , figure 2 As shown, the elastic suspension device for the shaft-mounted motor in this embodiment includes the motor end connecting ring 1 connected to the output end 11 of the shaft-holding motor rotor through the axial bolt 2, the axle end connecting ring 9 that is well matched with the axle, and the ring shaped elastic element 7, the peripheral walls of the motor end connecting ring 1 and the axle end connecting ring 9 are provided with bosses 3 and 4 at intervals, the bosses 3 of the motor end connecting ring 1 and the bosses 4 of the axle end connecting ring 9 are alternately distributed, The elastic element 7 is wrapped and fixed on the periphery of the bosses 3, 4, and the elastic element 7 has a wedge-shaped block 8 inserted into the gap between adjacent bosses. The outer surfaces of the bosses 3 and 4 offer radial screw holes, and the bolts 5 and 6 pass through the elastic elements to fix the elastic elements and the bosses 3 and 4, and pads ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com