Corrugated board lifting and stacking mechanism beneficial to transferring

A technology of corrugated cardboard and lifting mechanism, which is applied in the direction of stacking receiving device, thin material processing, transportation and packaging, etc., can solve the problem of low work efficiency and achieve the effect of solving extremely low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

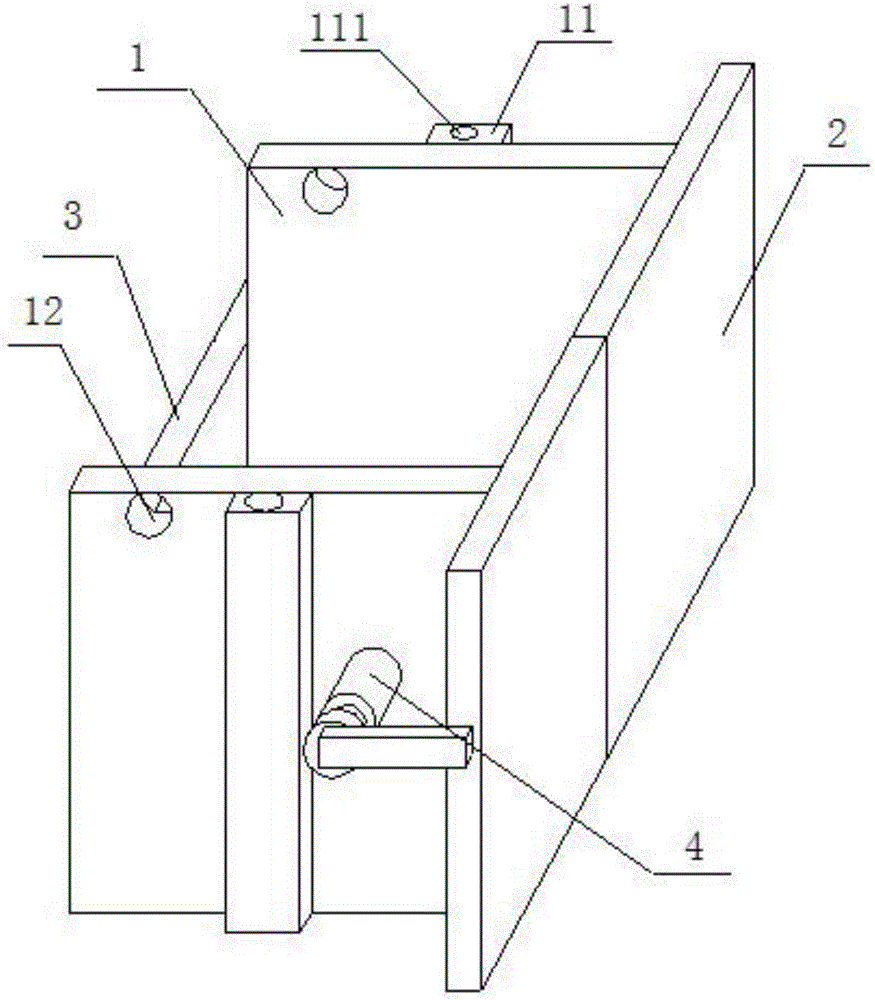

[0021] Such as figure 1 As shown, a corrugated cardboard lifting and stacking mechanism that is convenient to move is connected to a conveyor belt and a lifting mechanism, and includes two side plates 1, a sliding plate 2 and a fixed plate 3 consisting of a rectangular frame with open upper and lower ends. The two side plates 1 is arranged in parallel, the side plate 1 is provided with a sliding cylinder 4 for pulling the sliding plate 2 to slide, the sliding cylinder 4 is equipped with an electromagnetic switch, and the bottom of the sliding plate 2 is provided with a pressure sensor plate 21 facing into the rectangular frame. The pressure sensing plate 21 is connected with the switch of the lifting mechanism and the electromagnetic switch; the sliding plate 2 is provided with two, and the two sliding plates 2 slide inward or outward along the groove 13, and the pressure sensing plate 21 is arranged on two The side of the sliding plate 2 that is close to each other; the height ...

Embodiment 2

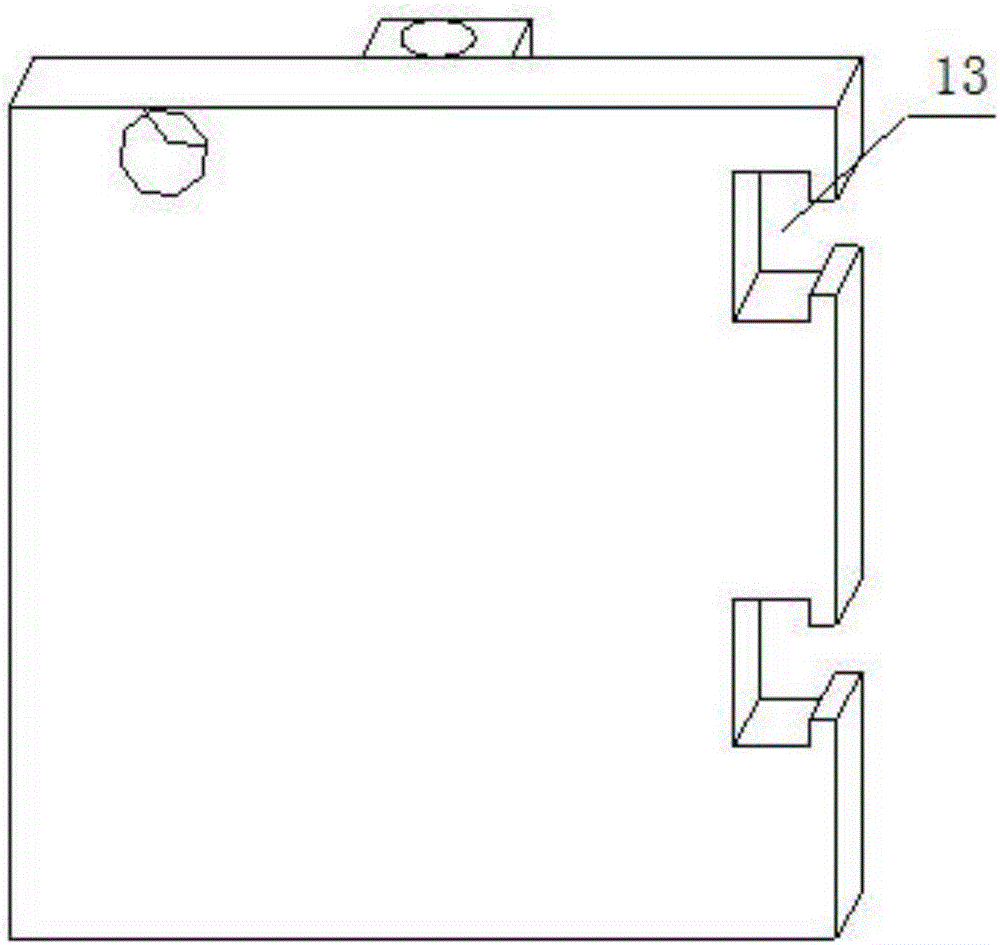

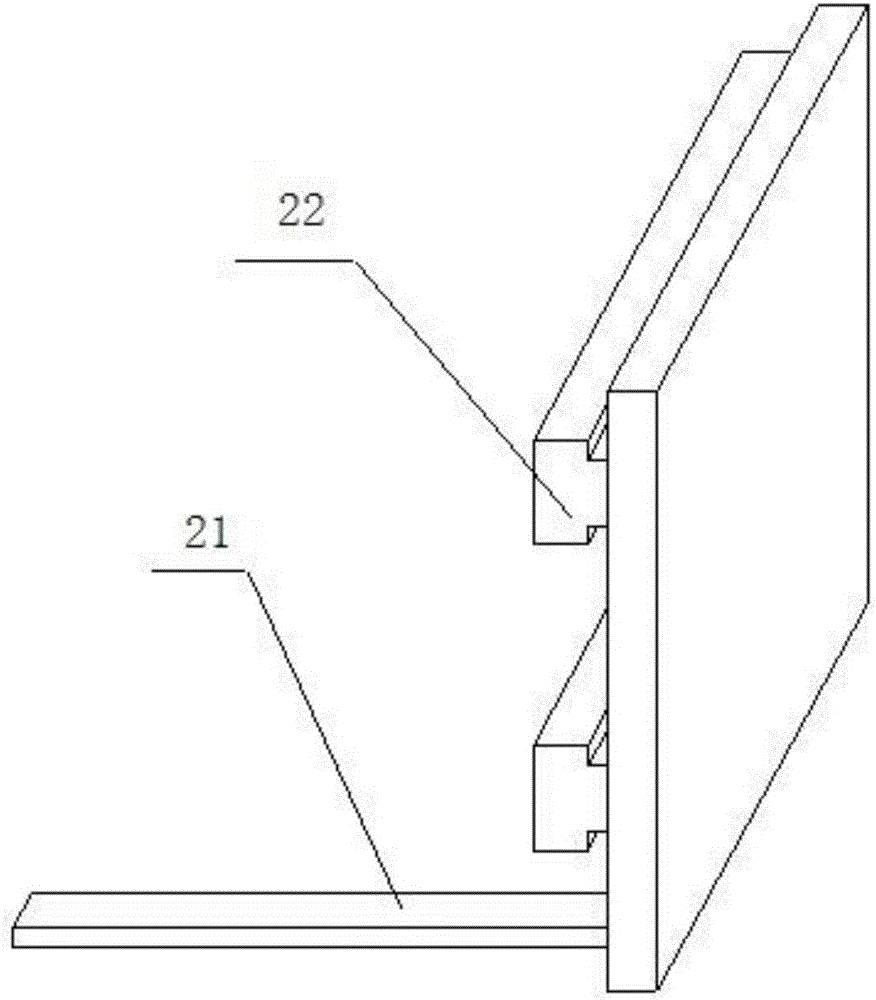

[0026] Such as figure 2 , image 3 As shown, on the basis of a corrugated cardboard lifting and stacking mechanism that is convenient to move described in embodiment 1, a groove 13 is provided on the side where the side plate 1 and the sliding plate 2 are connected, and the sliding plate 2 A sliding protrusion 22 corresponding to the groove 13 is provided at the corresponding position.

[0027] The arrangement of this embodiment limits the sliding track of the sliding plate 2, and has a simple structure and is easy to implement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com