A device for ultrasonically peeling graphite oxide

An ultrasonic wave and graphite technology, which is applied in the field of ultrasonic stripping graphite oxide devices, can solve the problems of difficult large-scale industrial promotion and high production costs, achieve the effect of improving the stripping speed and stripping effect, and ensuring product quality and characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing.

[0028] from Figure 1-11 As shown, the ultrasonic stripping graphite oxide device involved in the present invention is divided into two parts, which are respectively an ultrasonic control cabinet and an ultrasonic reaction kettle.

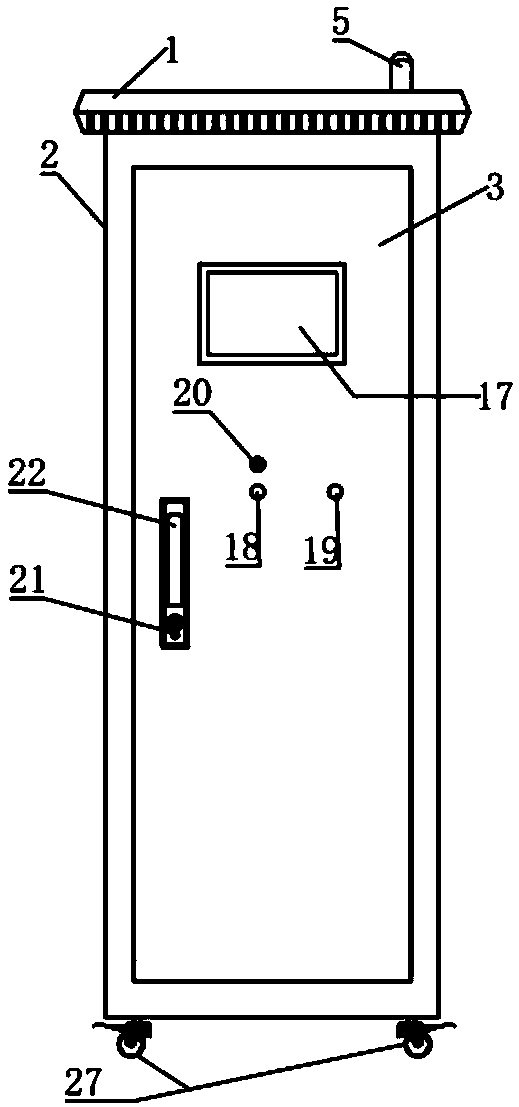

[0029] The ultrasonic control cabinet includes a dust cover 1, a cabinet body 2 and a cabinet door 3.

[0030] like Figure 1~6 As shown, there is a card slot on the edge of the dust cover 1 to be embedded with the top of the cabinet body 2, and is fixed on the top of the cabinet body 2 by bolts. A cooling fan 4 is fixed inside, and a warning light 5 is installed on the right side of the top. Both the edge 6 and the lower edge 7 have a plurality of vents 8 .

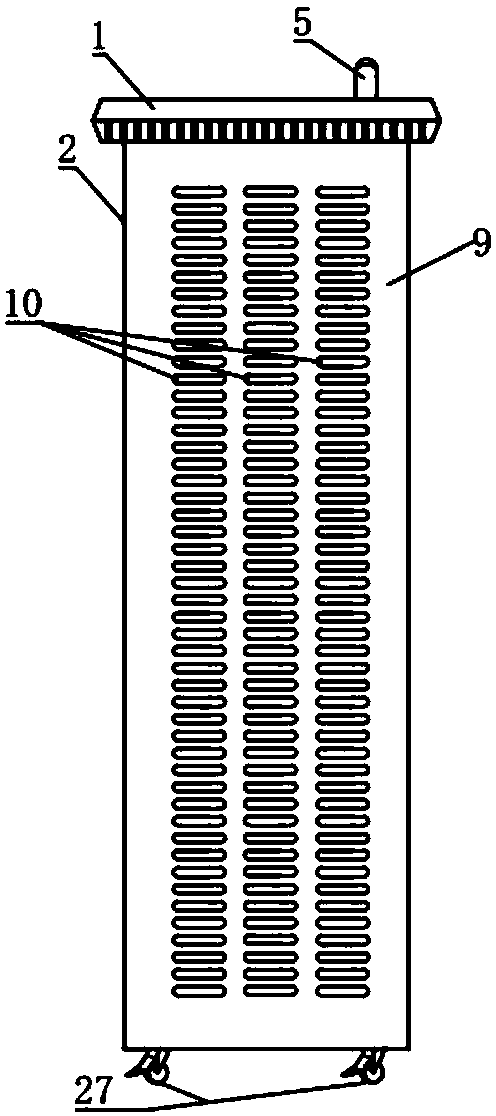

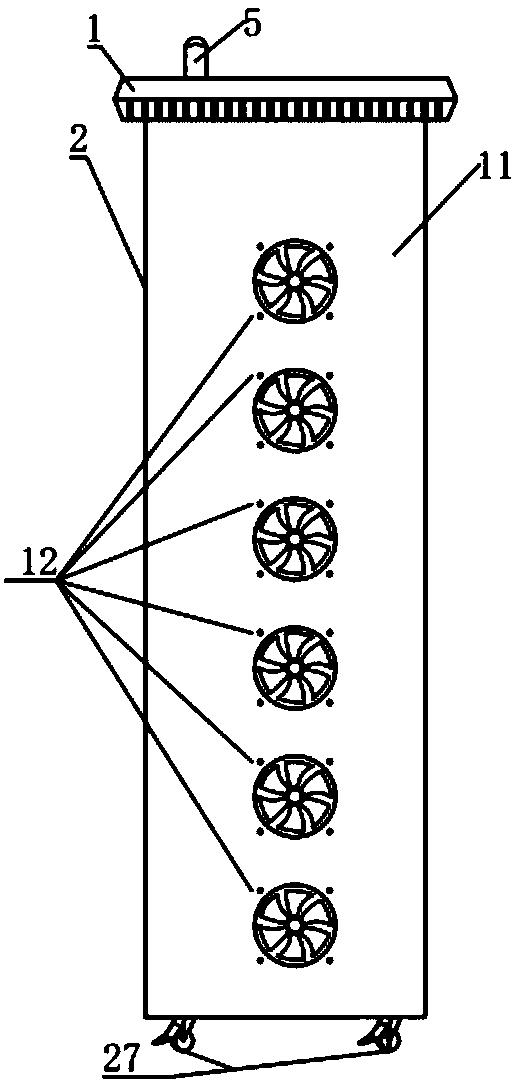

[0031] like figure 2 Shown, the left panel 9 of cabinet body 2 has three rows of shutters 10, and the right panel 11 is equipped with six cooling fans 12, as image 3 As shown, these...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com