Processing and firing method of purple clay green mud with natural pottery clay as raw material

A technology of pottery clay and purple sand, applied in the field of purple sand green clay processing and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

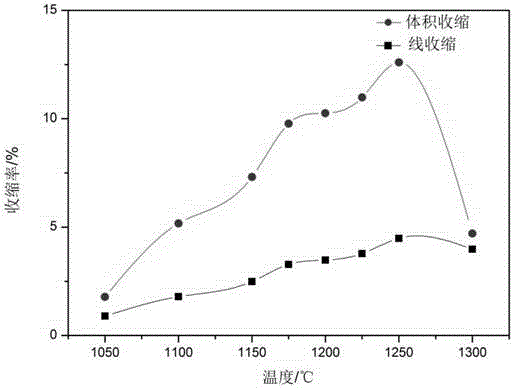

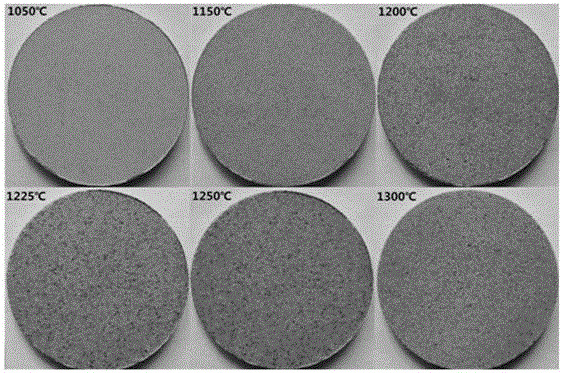

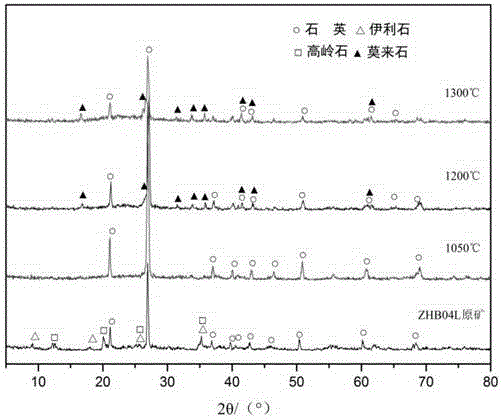

[0073] Example 1: A kind of purple sand green mud processing and firing method using natural pottery clay as raw material

[0074] This example uses natural clay as raw material without adding any chemical raw materials and artificial pigments, and uses dry method + wet method to process the purple sand green clay with particle sizes of -20 mesh, -40 mesh, -60 mesh, -80 mesh, and -100 mesh respectively. , using the optimized process to burn green clay purple sand, the processing and firing process is carried out according to the following 9 steps:

[0075] (1) Selection of pottery clay: select soil-agglomerate natural pottery ore, whose chemical composition is w(SiO 2 )50%~70%, w(Al 2 o 3 )22%~33%, w(Fe 2 o 3 )1%~3%, w(K 2 O)1%~4%, w(CaO)<1%;

[0076] (2) Drying and crushing: After the pottery clay is naturally dried, crushing equipment is used to process the pottery clay into powdery materials;

[0077] (3) Material screening: Use screening equipment to pass all the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com