Crosslinkable polyethylene composition, crosslinked polyethylene, preparing method, product and application

A cross-linked polyethylene and composition technology, applied in the application of the cross-linked polyethylene in polymer welding, cross-linked polyethylene and its preparation, cross-linkable polyethylene composition field, can solve the problem of not being able to have both Welding, high impact resistance and other issues to achieve the effect of improving impact performance, improving impact performance, and improving impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The present invention also provides a preparation method of the cross-linked polyethylene of the present invention, comprising: mixing 100 parts by weight of polyethylene, 0.01-0.03 parts by weight of a cross-linking agent and 0.05-0.2 parts by weight of a cross-linking assistant It is a cross-linkable polyethylene composition, and then cross-linked by heating at 180-200°C for 10-20 minutes; wherein, the polyethylene includes 25-55 parts by weight of linear low-density polyethylene and 45-75 parts by weight of high-density polyethylene polyethylene.

[0047] Preferably, the linear low density polyethylene has a density of 0.91 to 0.925 g / cm 3 , the melt index is 1-5g / 10min; the density of the high-density polyethylene is 0.94-0.96g / cm 3 , The melt index is 5-10g / 10min.

[0048] Preferably, said high density polyethylene has a greater melt index than said linear low density polyethylene.

[0049] According to the present invention, preferably, the effective oxygen con...

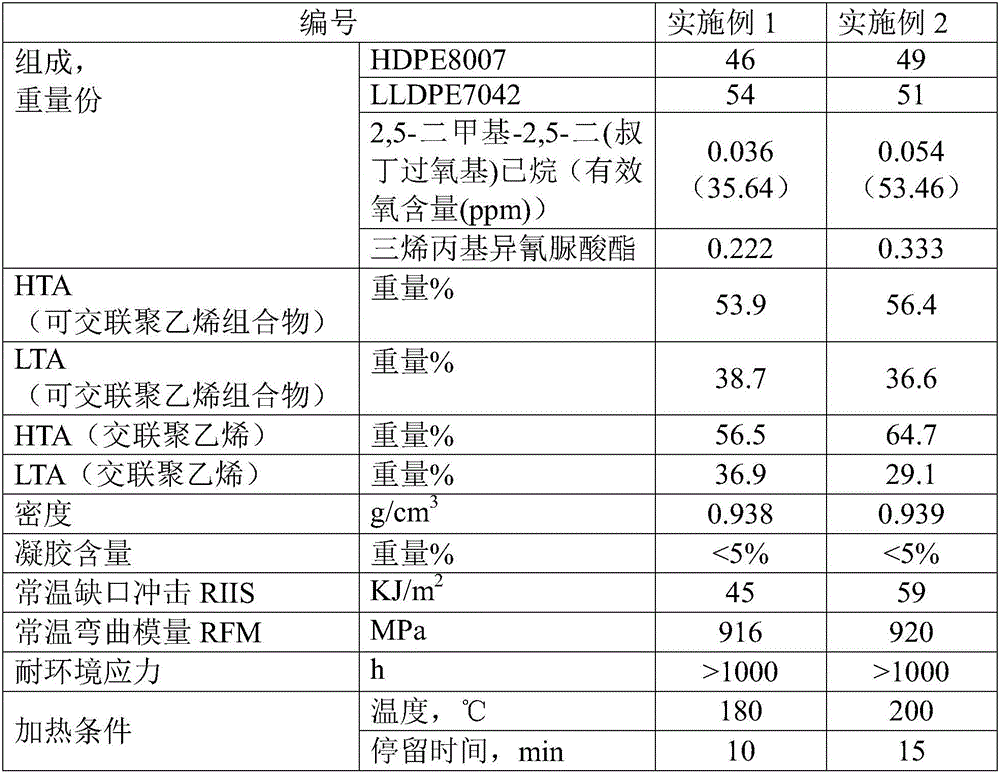

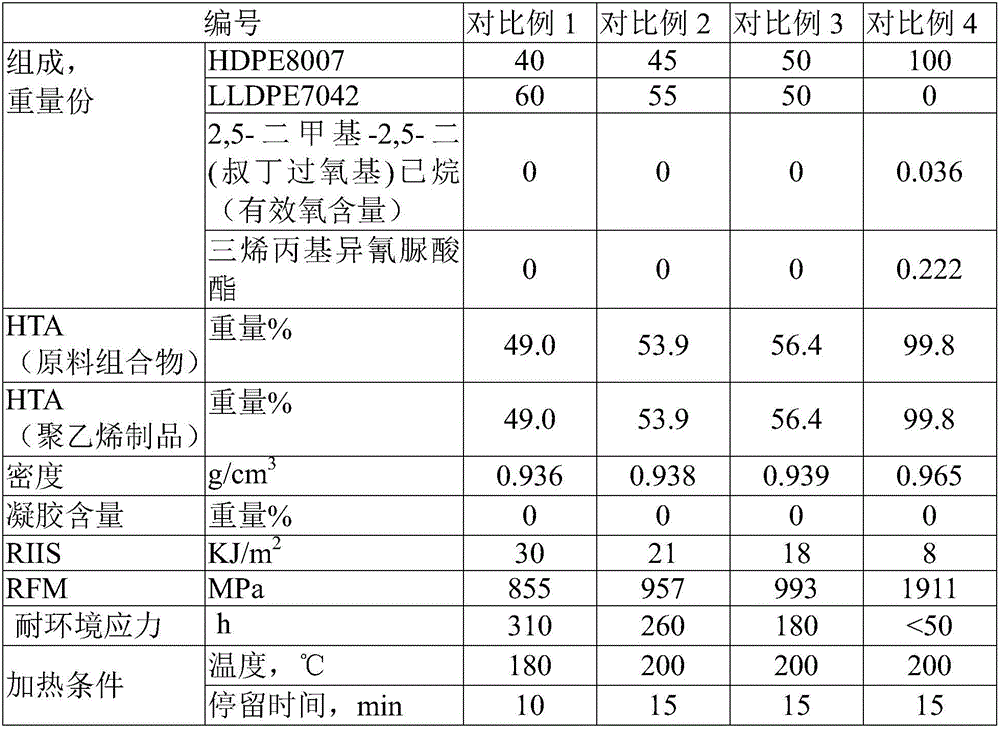

Embodiment 1-2

[0075] This example illustrates the preparation of the crosslinked polyethylene of the present invention.

[0076] Feed materials according to the composition listed in Table 1, and stir with a high-speed mixer for 5 minutes until the mixture is uniform, and then melt, cross-link, blend and granulate through a low-shear twin-screw extruder to obtain cross-linked polyethylene. The screw aspect ratio of the twin-screw extruder is 18 / 1, the screw speed is 100rpm, the temperature of the twin-screw extruder is 180-200°C, and the material residence time is 10-20min.

[0077] The cross-linked polyethylene was measured, HTA, LTA, gel content, impact performance, flexural modulus, environmental stress, the results are shown in Table 1.

[0078] Table 1

[0079]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com