Water block removing agent and preparation method thereof

A technology for releasing water lock agent and water agent, which can be used in chemical instruments and methods, drilling compositions, etc., and can solve problems such as difficulty in damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment provides a dehydrating and locking agent, which is composed of the following substances in weight percentage: 10-12% of weak hydrophilic agent, 8-10% of acid-soluble oxidizing agent, 0.5-1.5% of corrosion inhibitor, and the balance is water.

[0027] The preparation method comprises the following steps:

[0028] Step 1) Weigh the weak hydrophilic agent, acid-soluble oxidant, corrosion inhibitor of formula quantity, or prepare the weak hydrophilic agent, acid-soluble oxidant of formula quantity, and fill the weak hydrophilic agent and acid-soluble oxidant respectively into cans ;

[0029] Step 2) During on-site construction, add the formulated amount of water into the preparation tank, add the prepared weak hydrophilic agent and acid-soluble oxidant into the water at room temperature while stirring, and finally add the corrosion inhibitor and stir evenly to obtain the water-blocking agent.

[0030] Principle of the present invention:

[0031] The weak h...

Embodiment 2

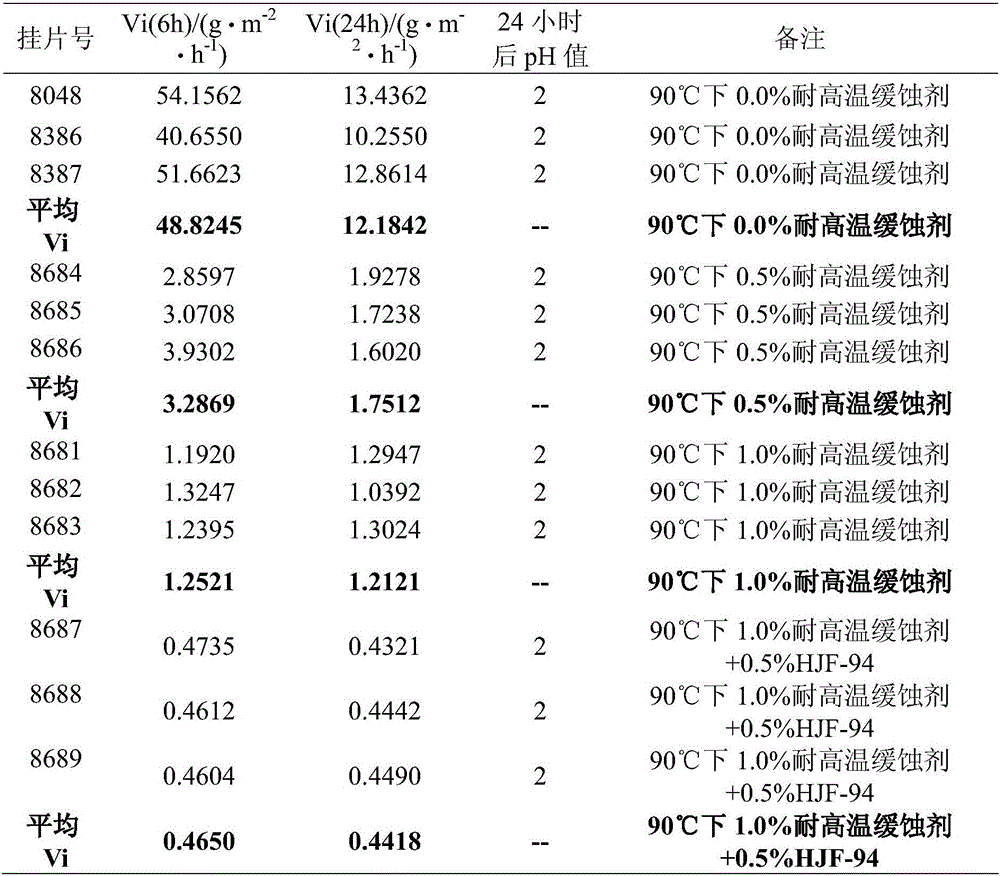

[0033] On the basis of Example 1, the present embodiment has prepared corrosion inhibitors (0.5-1.5%) of different weight percentages, and the consumption of corrosion inhibitors is optimized, wherein, weak hydrophilic agent 11%, by the following weight percentages Material composition, ethylene glycol methyl ether 1.0%, fluoroalkyl quaternary ammonium salt surfactant 0.05%, volume fraction is 95% ethanol 78%, the balance is water; Acid-soluble oxidizing agent 9%, consists of the following substances in weight percentage It consists of 16% sodium nitrate, 14% potassium fluoride, 40.0% HCL with a mass concentration of 37%, and the balance being water.

[0034] Fluoroalkyl quaternary ammonium salt surfactants are extremely difficult to dissolve in water. Ethylene glycol methyl ether must be added to dissolve the surfactant. At the same time, ethanol can increase the gas permeability, and fluoroalkyl quaternary ammonium salt surfactants can Surface tension, the function of releas...

Embodiment 3

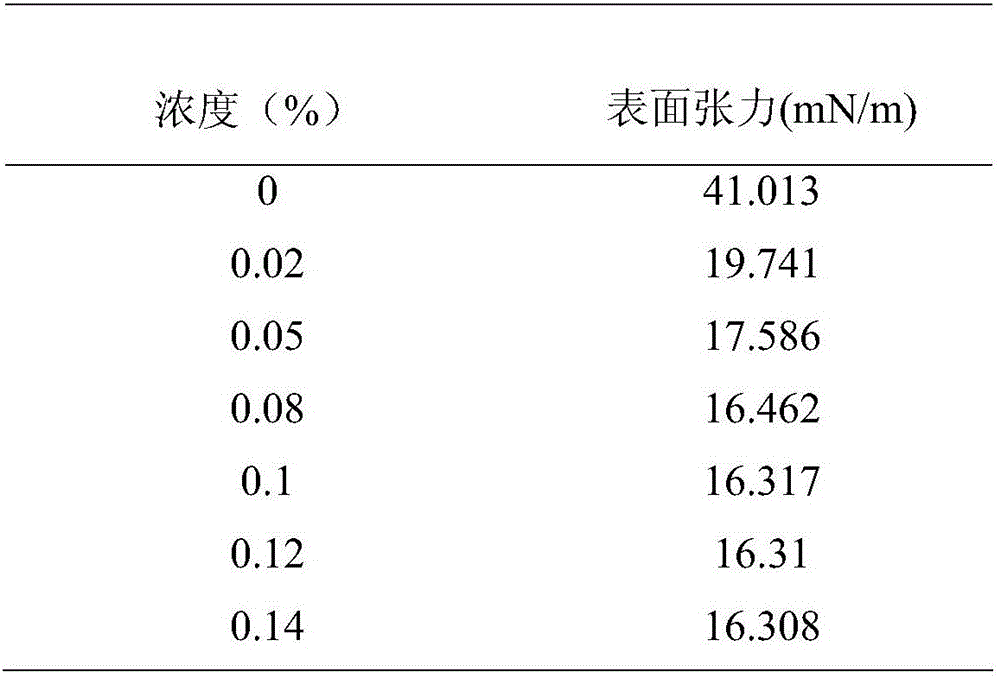

[0041] This embodiment provides a dehydrating and locking agent, which is composed of the following substances in weight percentage: 11% of weakly hydrophilic agent, 9% of acid-soluble oxidant, 1.5% of corrosion inhibitor, and the balance is water. Among them, the corrosion inhibitor is 1.0% nitrogen-containing imidazoline + 0.5% HJF-94 corrosion inhibitor.

[0042] Wherein, the weak hydrophilic agent is composed of the following substances by weight percentage, 1.0% of ethylene glycol methyl ether, 0.05% of fluoroalkyl quaternary ammonium salt surfactant, 78% of ethanol with a volume fraction of 95%, and the balance is water; The soluble oxidizing agent is composed of the following substances in weight percentage, 16% of sodium nitrate, 14% of potassium fluoride, 40.0% of HCL with a mass concentration of 37%, and the balance is water.

[0043] In this example, different weight percentages of fluoroalkyl quaternary ammonium salt surfactants (0.02-0.16%) were prepared to optimize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average corrosion rate | aaaaa | aaaaa |

| Average corrosion rate | aaaaa | aaaaa |

| Average corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com