Single phase sewage cutting pump

A sewage, single-phase technology, used in pumps, pump components, pump devices, etc., can solve the problems of reduced impeller service life, high energy consumption and high cost of high-power motors, reducing manufacturing costs, improving work efficiency, and prolonging use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

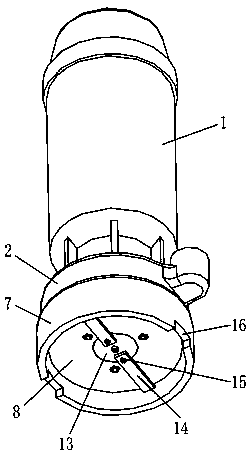

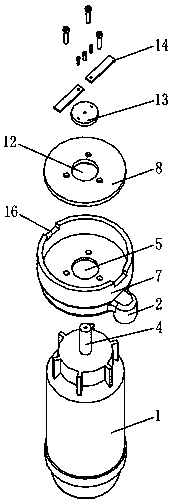

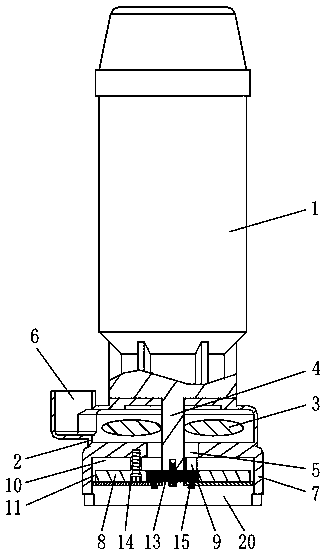

[0021] see Figure 1 to Figure 4 , the present invention provides a single-phase sewage cutting pump, comprising a motor 1 and a pump body 2, the motor 1 is a single-phase low-power motor, the pump body 2 is provided with an impeller 3, the impeller 3 is connected to the motor shaft 4, A water inlet 5 is provided at the bottom of the pump body 2, and a water outlet 6 is provided at the side of the pump body 2. A cutting device is provided at the bottom of the pump body 2, and the cutting device includes a circle formed by extending downward from the bottom of the pump body 2. An annular casing 7 concentric with the motor shaft 4, a fixed plate 8 fixed on the bottom of the pump body 2 concentric with the casing 7, a spacer 9 is arranged between the fixed plate 8 and the bottom of the pump body 2, and the spacer 9. An overhead layer 10 is formed between the fixed plate 8 and the bottom of the pump body 2; there is a gap 11 between the outer periphery of the fixed plate 8 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com