A U-shaped microchannel dehumidification heat pipe and its application method

A micro-channel, dehumidification heat technology, applied in the field of heat pipes, can solve the problems of inflexible overall size design of dehumidification heat pipes, high production and maintenance costs, inconvenient installation and use, etc., and achieves flexible and convenient design, simple structure, and high degree of automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

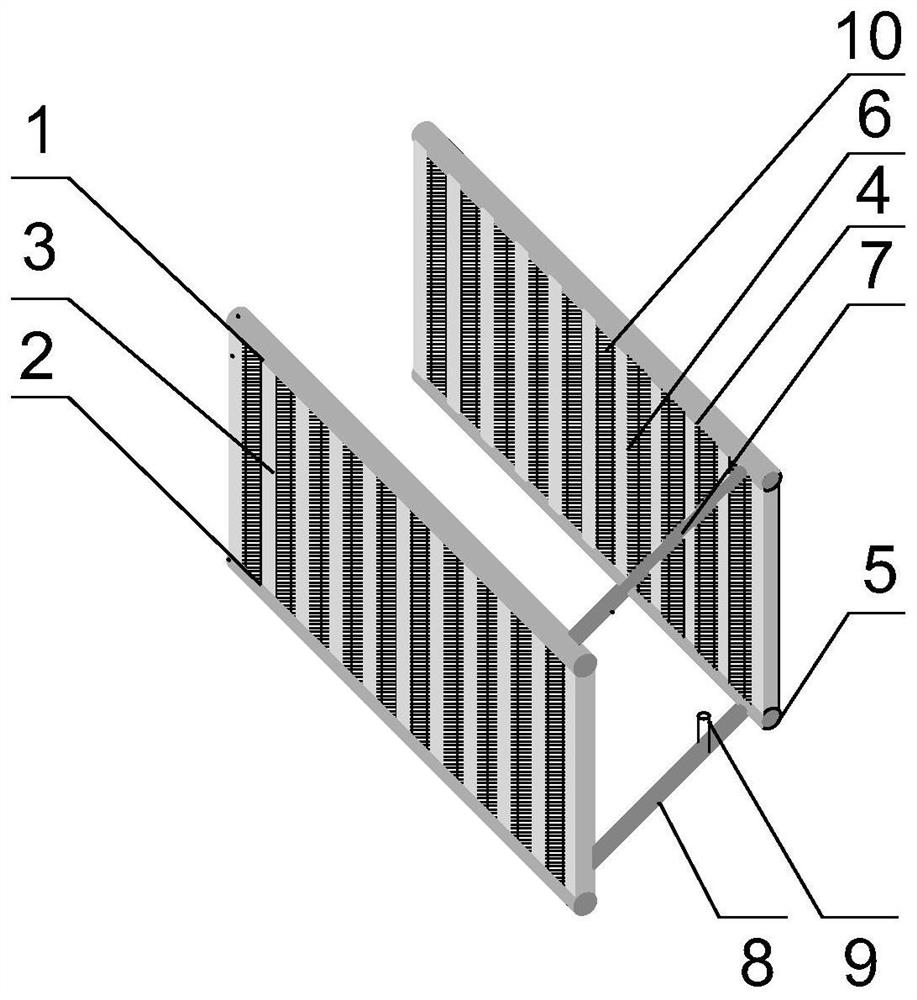

[0020] Attached below figure 1 A U-shaped microchannel dehumidification heat pipe of the present invention and its application method are described in detail.

[0021] A U-shaped microchannel dehumidification heat pipe, the U-shaped microchannel dehumidification heat pipe includes a first part arranged on the front side of the surface cooler, a second part arranged on the rear side of the surface cooler, and connecting the first part and the second part The third part; wherein, the first part includes the first gas pipe 1 and the refrigerant liquid inlet pipe 2, and also includes the first microchannel branch pipe 3 communicated with the first gas pipe and the refrigerant liquid inlet pipe respectively; The second part includes the second gas pipe 4 and the refrigerant liquid return pipe 5, and also includes the second microchannel branch pipe 6 communicated with the second gas pipe and the refrigerant liquid return pipe; the third part includes the first gas pipe and the refr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com