Air conditioner windshield driving device

A driving device and wind baffle technology, applied in space heating and ventilation details, heating methods, lighting and heating equipment, etc., can solve the problems of difficult adjustment of motion trajectory, high production cost, and high design difficulty, and achieve opening and closing The effect of easy angle, simple structure and reduced design cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

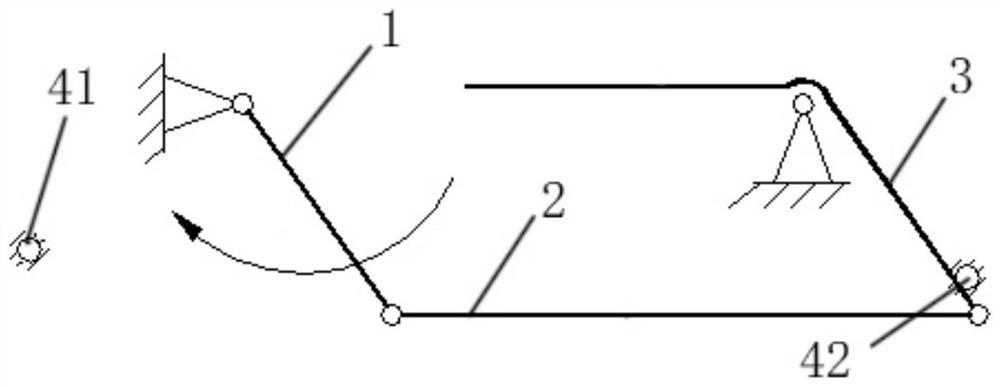

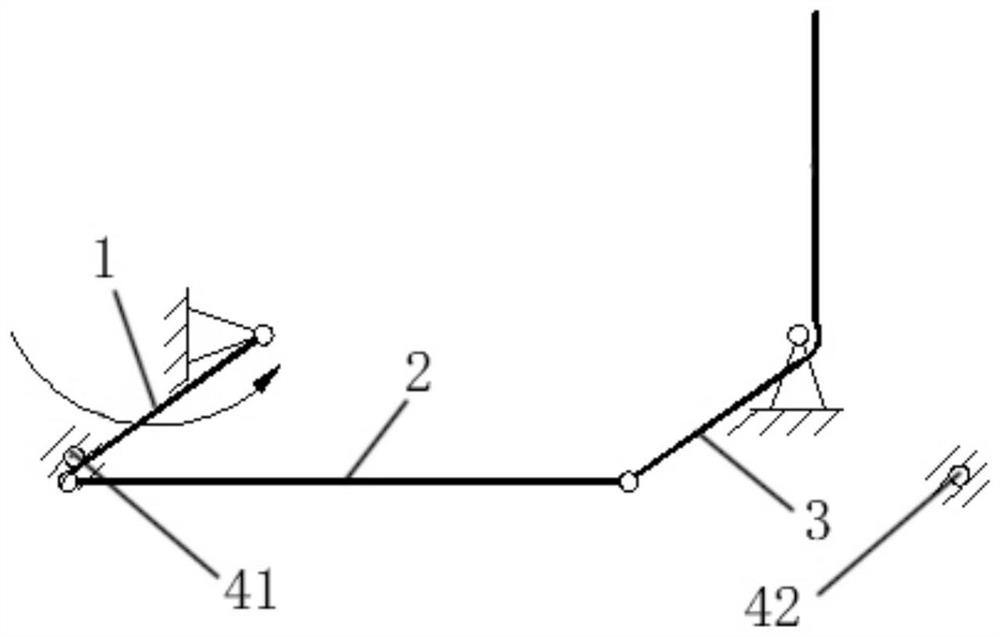

[0029] refer to figure 1 and figure 2 , the present embodiment provides a driving device for the wind baffle of an air conditioner, the driving device includes a driving motor, fixedly installed on a fixed frame, and has a drive shaft with a fixed position relative to the fixed frame; the baffle shaft is wound around the The tuyere rotates relative to the fixed axis of the fixed frame, the baffle shaft is parallel to the drive shaft; and a transmission device is arranged between the drive shaft and the baffle shaft to move the The rotational torque of the drive shaft is transmitted to the flap shaft. Wherein, the transmission device includes a first connecting rod 1 whose one end is fixedly connected with the drive shaft, a second connecting rod 2 whose one end is fixedly connected with the wind baffle and the baffle shaft, and the two ends are respectively hinged to the first connecting rod through the first hinge point. The connecting rod 2 and the third connecting rod 2 ...

Embodiment approach

[0033] An alternative embodiment is to change the positions of the first limiter 41 and the second limiter 42, so as to realize the function of adjusting the unfolded and closed positions of the windshield, for example, to move the position of the first limiter 42 toward figure 1 Move the middle left side horizontally to increase the deployment angle of the wind deflector. Similar alternative implementation manners will not be described in detail.

[0034] Another alternative embodiment is to shorten the length of the second connecting rod 3 without changing the position of the baffle axis, while extending the length of the third connecting rod 2 to increase the rotation rate of the wind baffle. Similar alternative implementation manners will not be described in detail.

[0035] It should be noted that, when driving a wind baffle, one wind baffle driving device of an air conditioner described in the above-mentioned embodiment may be used, or multiple same wind baffle driving de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com