Wheel service machine with compact sensing device

A sensing device and wheel technology, applied in the field of determining the geometric dimensions of wheels, such as wheels, can solve problems affecting the accuracy of measurement or positioning results, complex structures, impurity sensitivity, etc., to reduce the risk of measurement errors and damage, structure Smaller, simpler effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

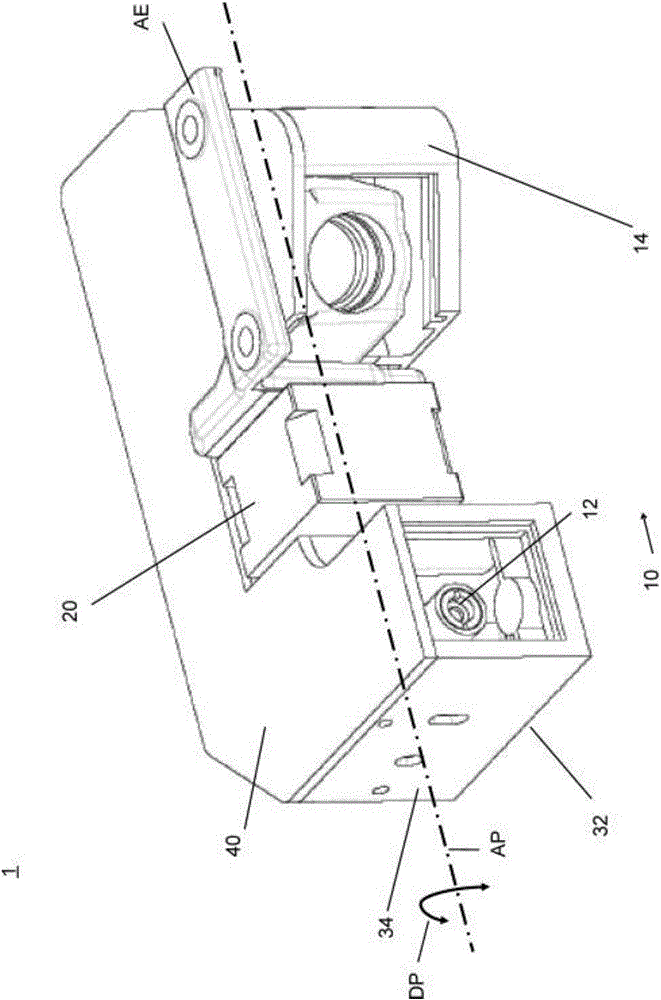

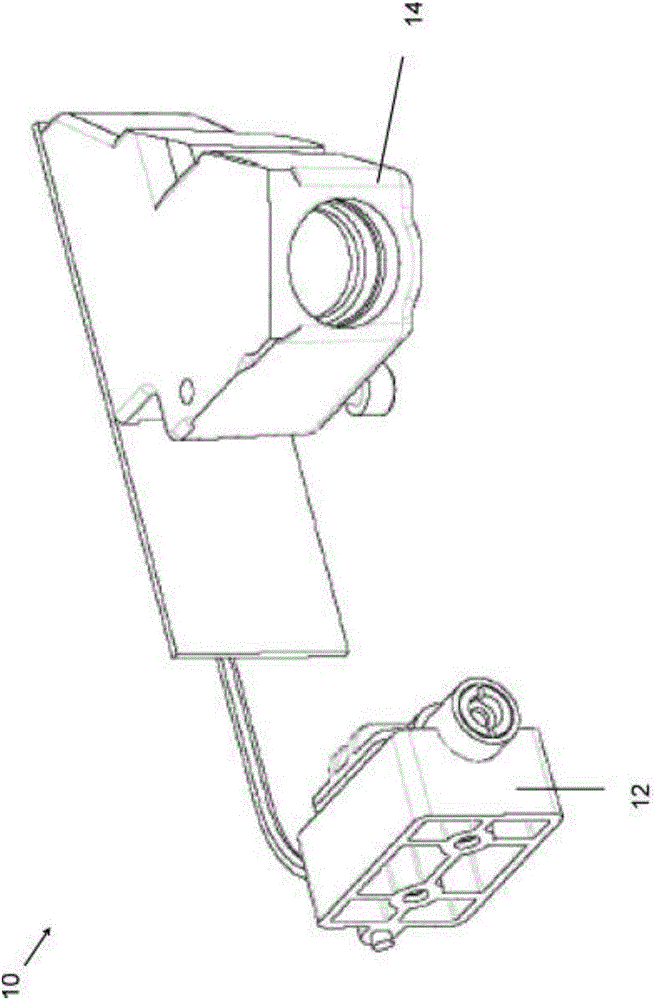

[0034] figure 1 is a schematic perspective view of a sensing device 1 according to an embodiment of the present invention. The sensing device 1 includes, as its main components, a first sensing unit 10 and a second sensing unit (not shown), the first sensing unit is preferably an optical sensing unit, and the second sensing unit Includes position sensitive components. The sensing device 1 also includes a housing 30 and a cover 40 provided at an upper end of the housing 30 .

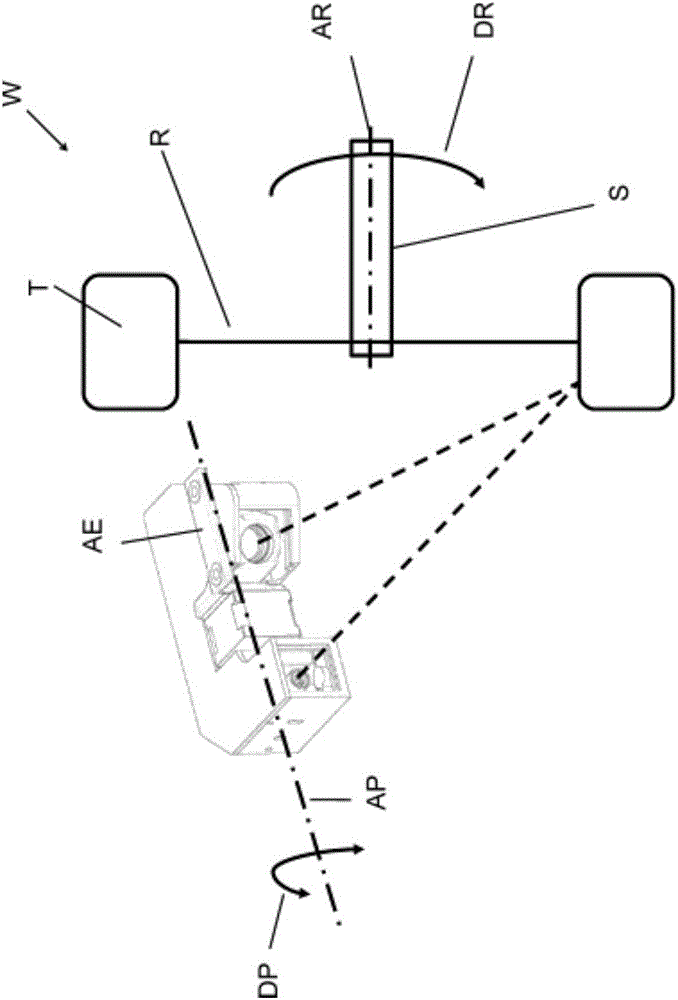

[0035] exist figure 1 , the drive device 20 is also shown, which can be coupled to the frame of the wheel repairing machine 50 via attachment elements AE (cf. figure 2 ). The drive means 20 , which is a micro-stepping motor, comprises a motor shaft to which the sensing means 1 is coupled so as to perform a pivoting movement. The motor shaft of the drive means or motor 20 provides a pivot axis AP about which the sensing means 1 pivots in a pivot direction DP.

[0036] In this example, the drive me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com