Patents

Literature

35results about How to "Improve scan accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multi-azimuth mobile scanner

InactiveCN106412369AImprove general performanceSmooth motionPictoral communicationEngineeringBlock match

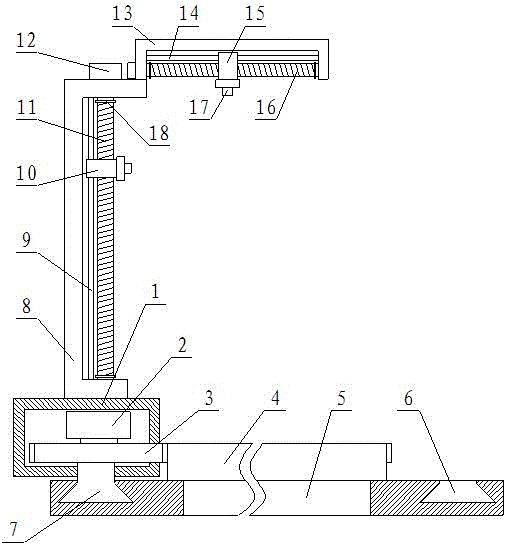

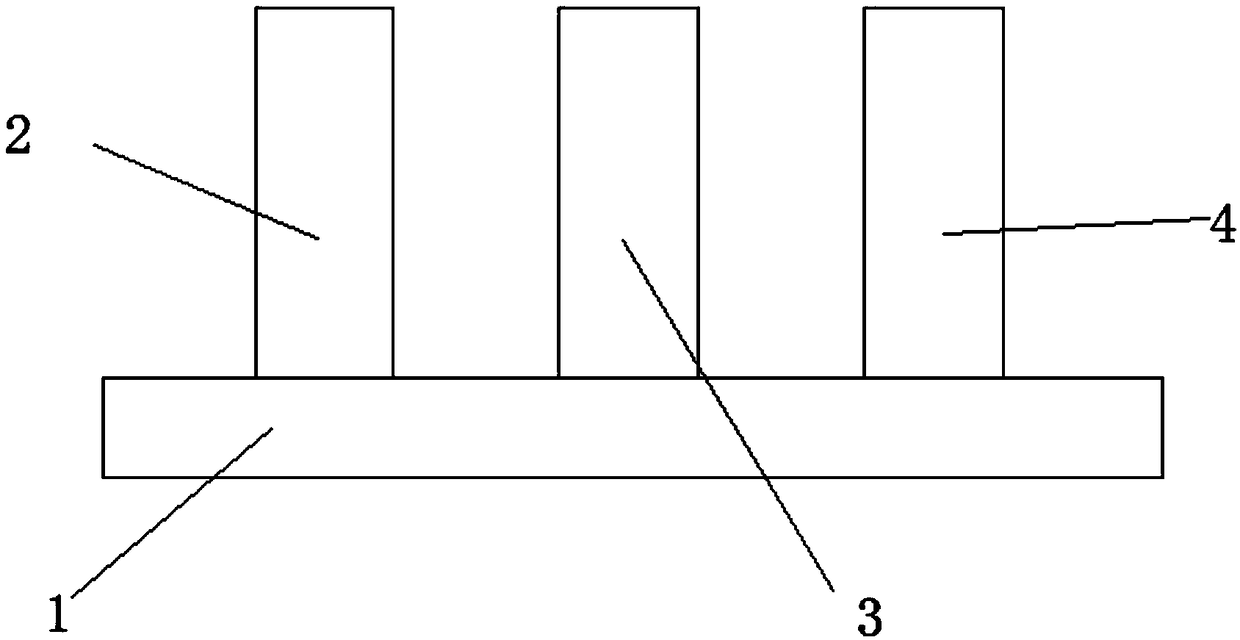

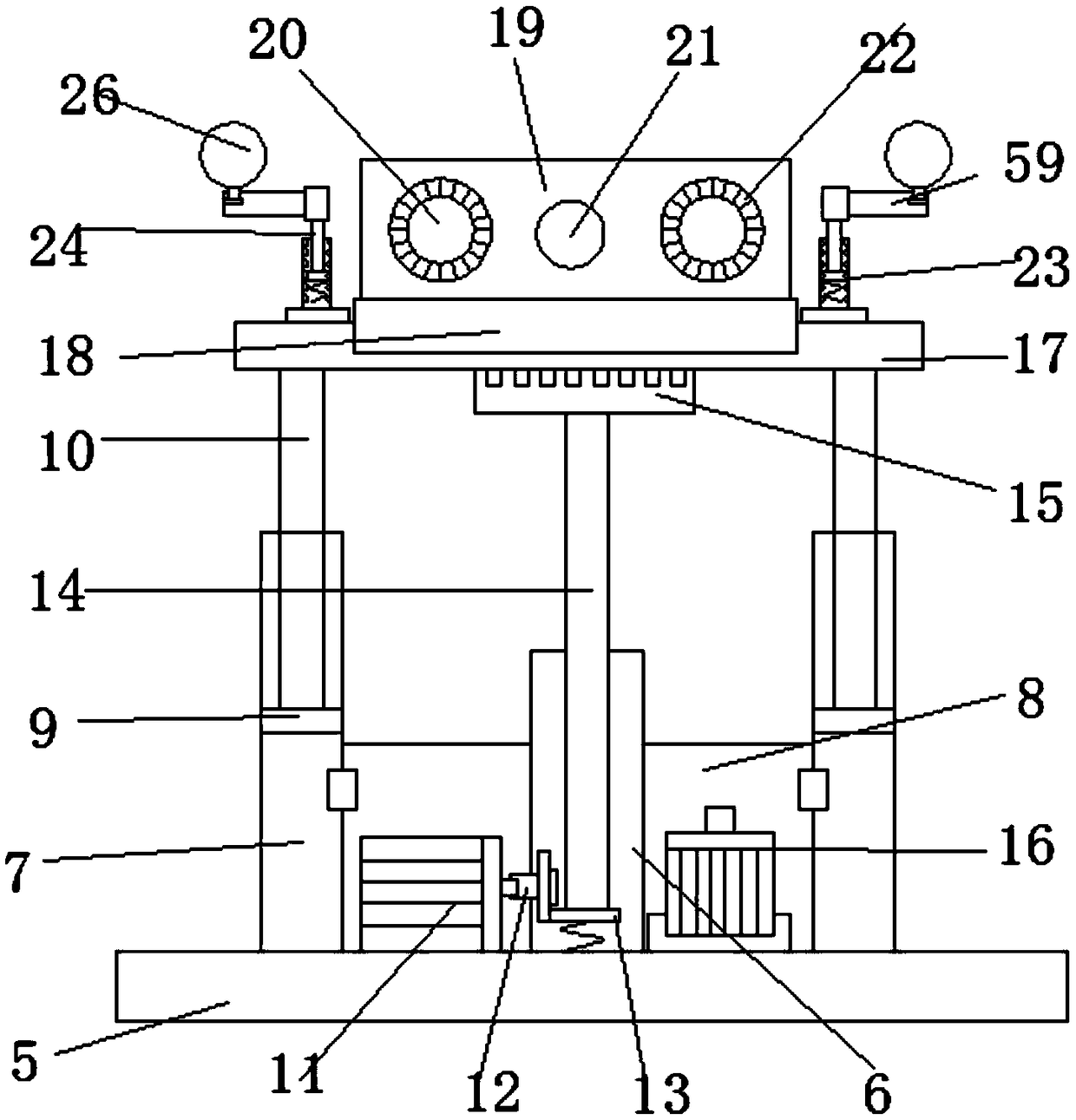

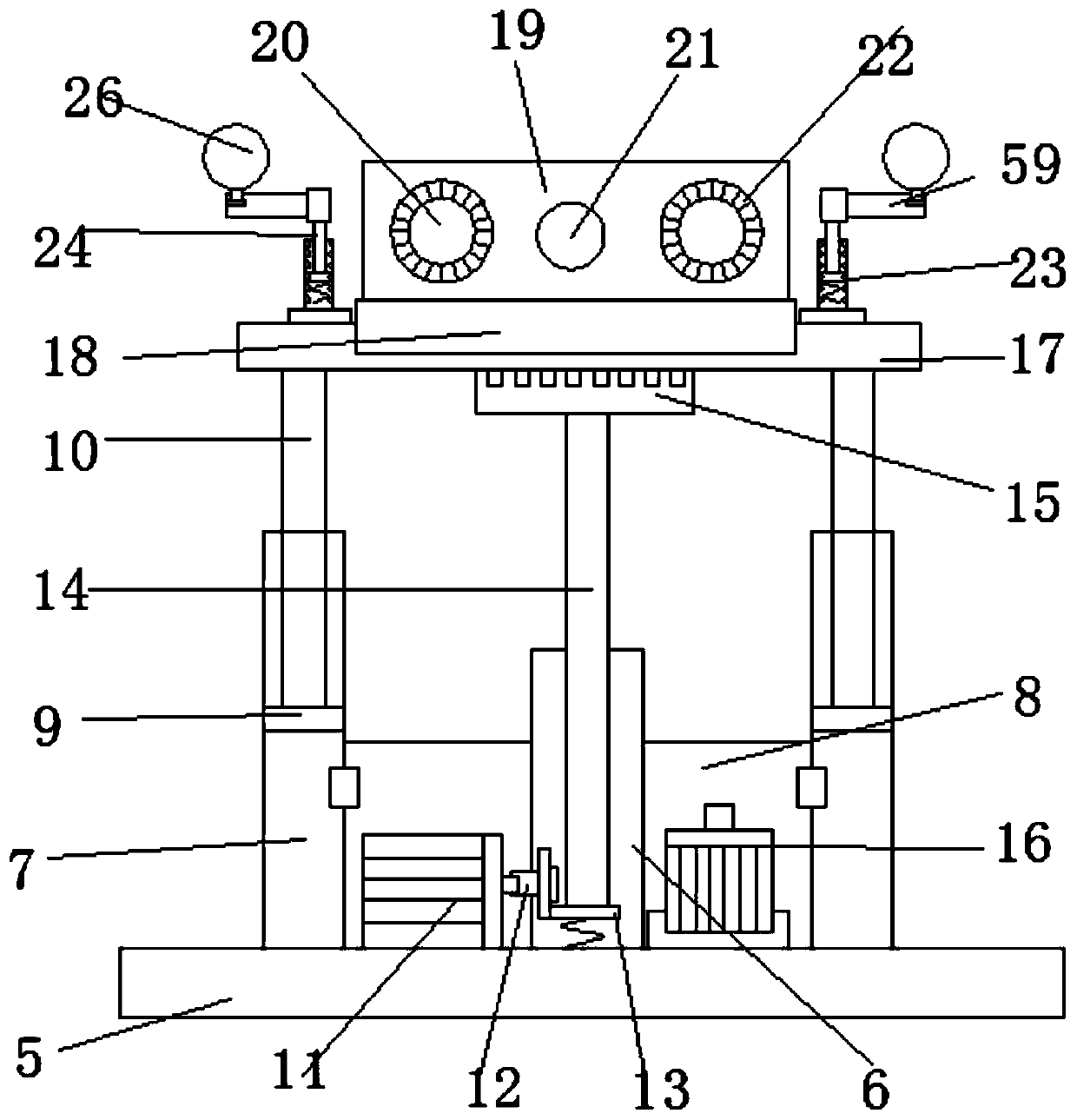

The invention relates to a multi-azimuth mobile scanner comprising a base, wherein a driving device A is arranged in the base, a gear is connected to an output shaft to the driving device A, the gear is engaged with a gear ring on a right side of the gear, the gear ring is fixed to an upper surface of a supporting platform, an annular chute is formed in an outer side of the gear ring on the upper surface of the supporting platform, a slide block matched with the chute is arranged in the chute, a vertical supporting frame is arranged on the upper surface of the base, a horizontal supporting frame is fixed to the upper surface of the vertical supporting frame, a vertical guide rod and a horizontal guide rod are separately arranged on the vertical supporting frame and the horizontal supporting frame, a camera bracket A and a camera bracket B are separately arranged on the vertical guide rod and the horizontal guide rod in a sliding manner, scanning cameras are separately fixed to the camera bracket A and the camera bracket B, and the camera bracket A and the camera bracket B are separately connected with a vertical screw and a horizontal screw by threads; and in summary, the multi-azimuth mobile scanner provided by the invention has the advantages of reasonable structural design, high scanning accuracy and strong universality.

Owner:HENAN LONGJING TECH

Method for realizing fast page number identification based on template matching

ActiveCN107766854ASolve adhesionImprove accuracyCharacter and pattern recognitionContinuous scanningTemplate matching

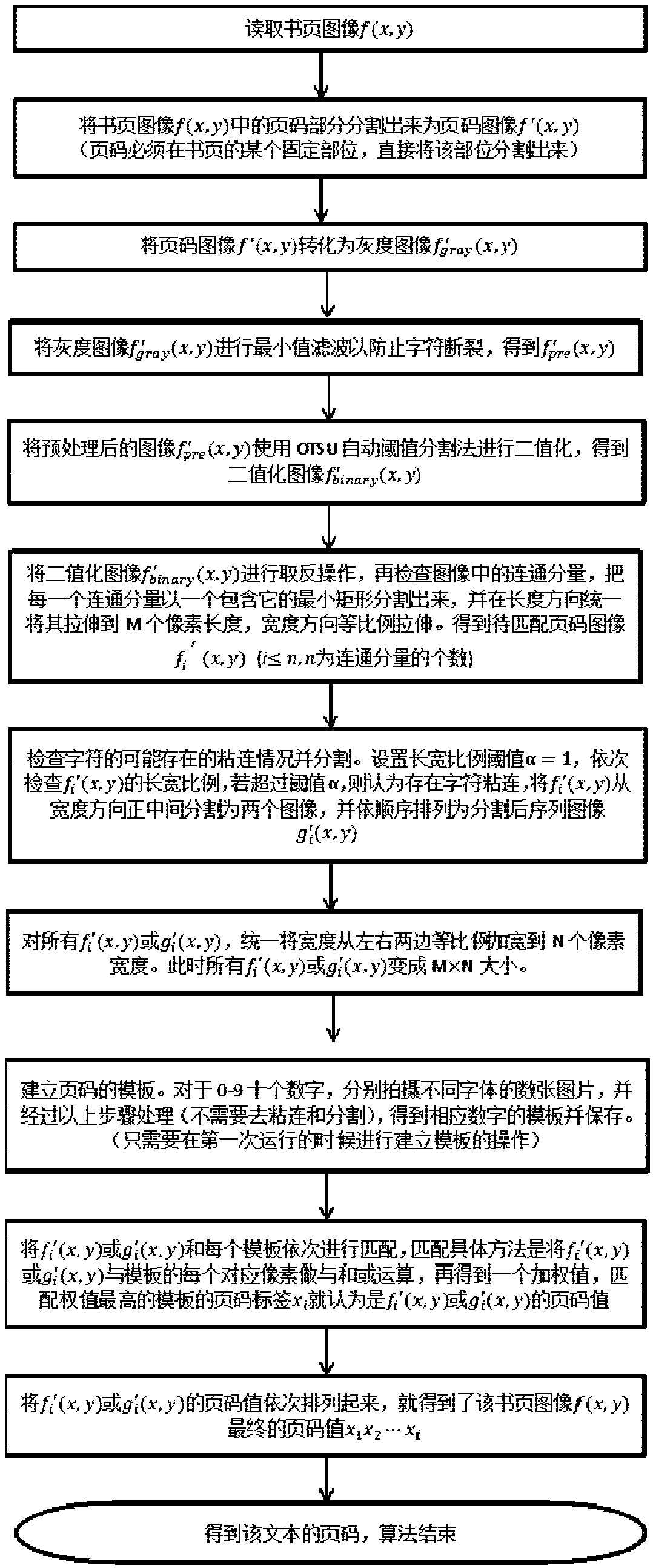

The invention discloses a method for realizing fast page number recognition based on template matching, and is aimed at the problem of low accuracy of page number recognition and scanning due to the failure to solve the problem of digit touching in page number recognition in the prior art. In this application, the page number segmentation and image normalization processing is skillfully performed,the problem of page number touching can be simply and quickly solved, the accuracy of page number recognition is improved, the accuracy of the entire scan is improved, meanwhile, the technical problems of wasting a large amount of scanning time and affecting the scanning efficiency and scanning accuracy in order to solve the problem of page number touching in the prior art are overcome, a template and a page number image to be detected are both subjected to normalization processing at the same time, the efficiency of the matching between the two at the later stage is increased, and the scanning efficiency is thus improved; in the meantime, the method in the application skillfully combines the page number of a next page with the page number of the current page, thereby avoiding the cases of mistakes in page turning and omissions of scanning and overcoming the technical difficulties of the continuous scanning of books in the prior art; and the method in the application is applicable tothe field of intelligent recognition in machine vision industrial applications.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

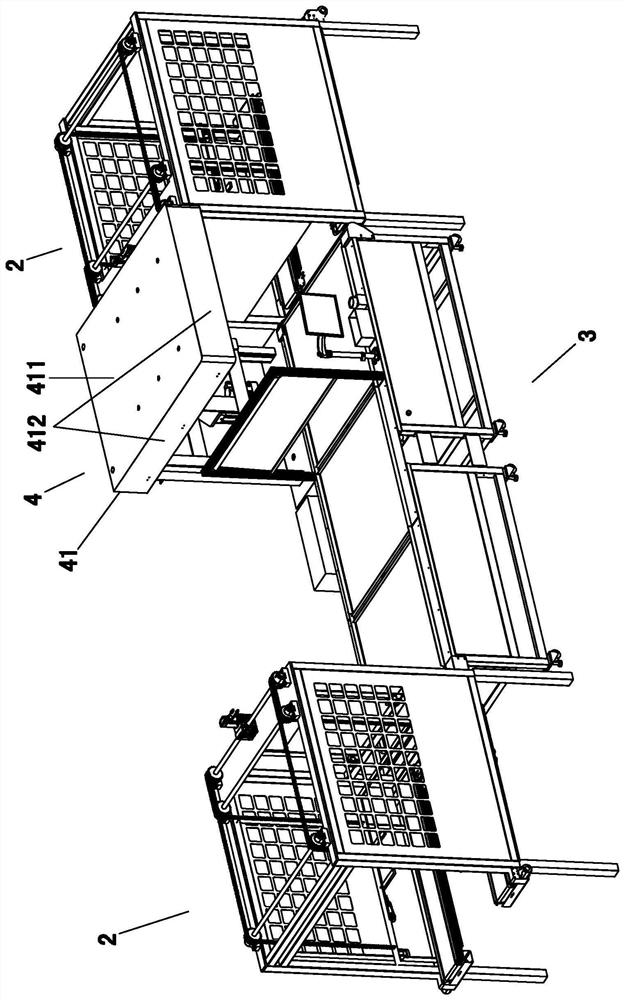

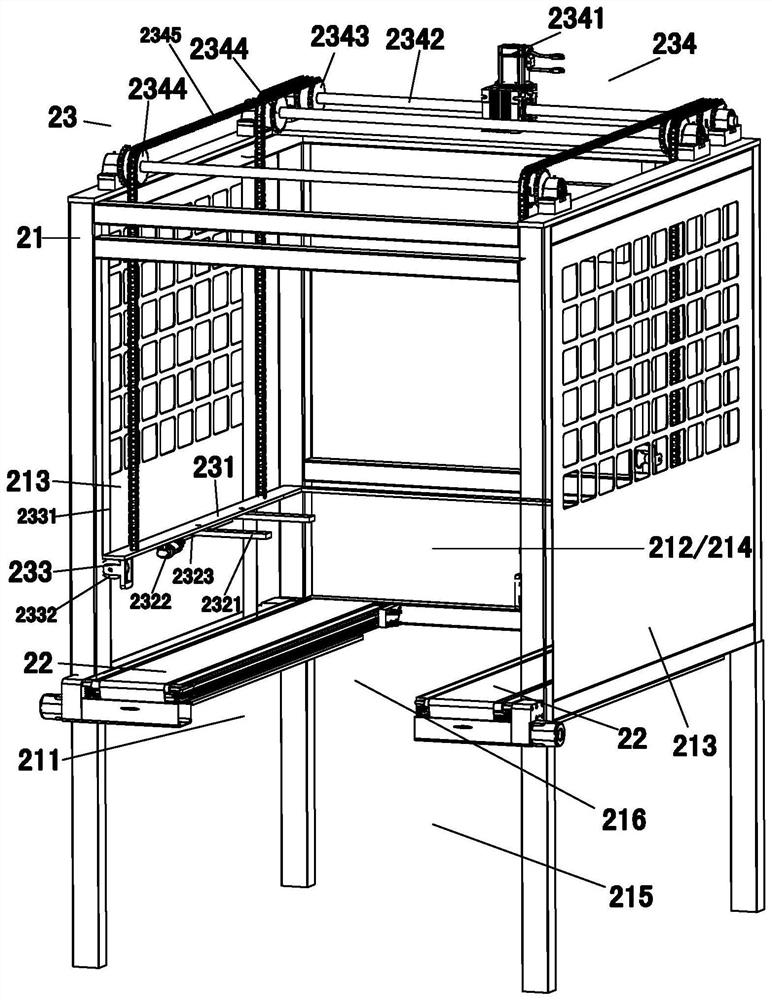

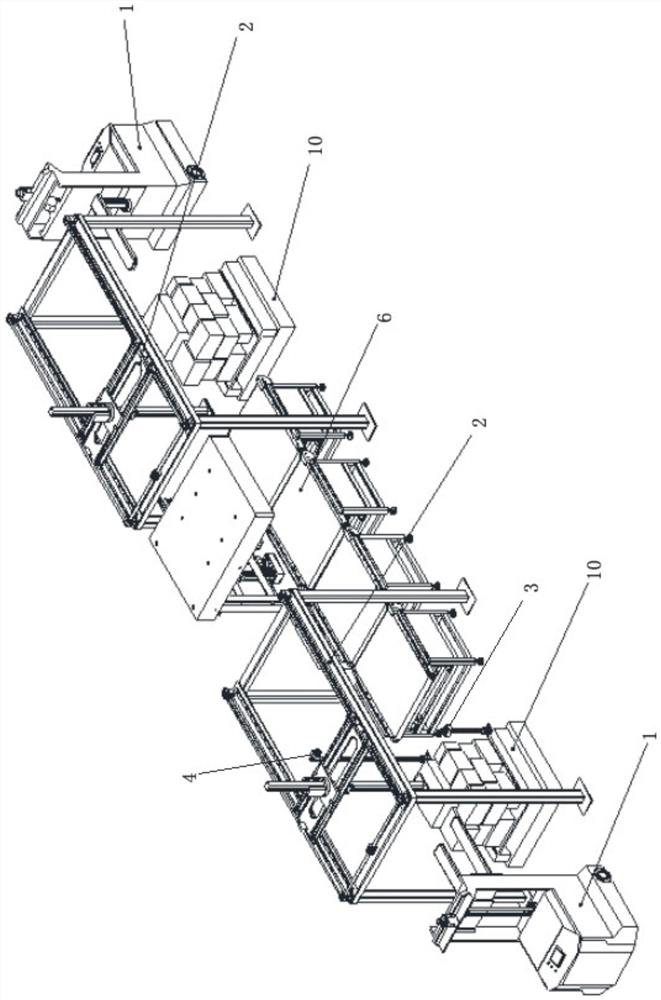

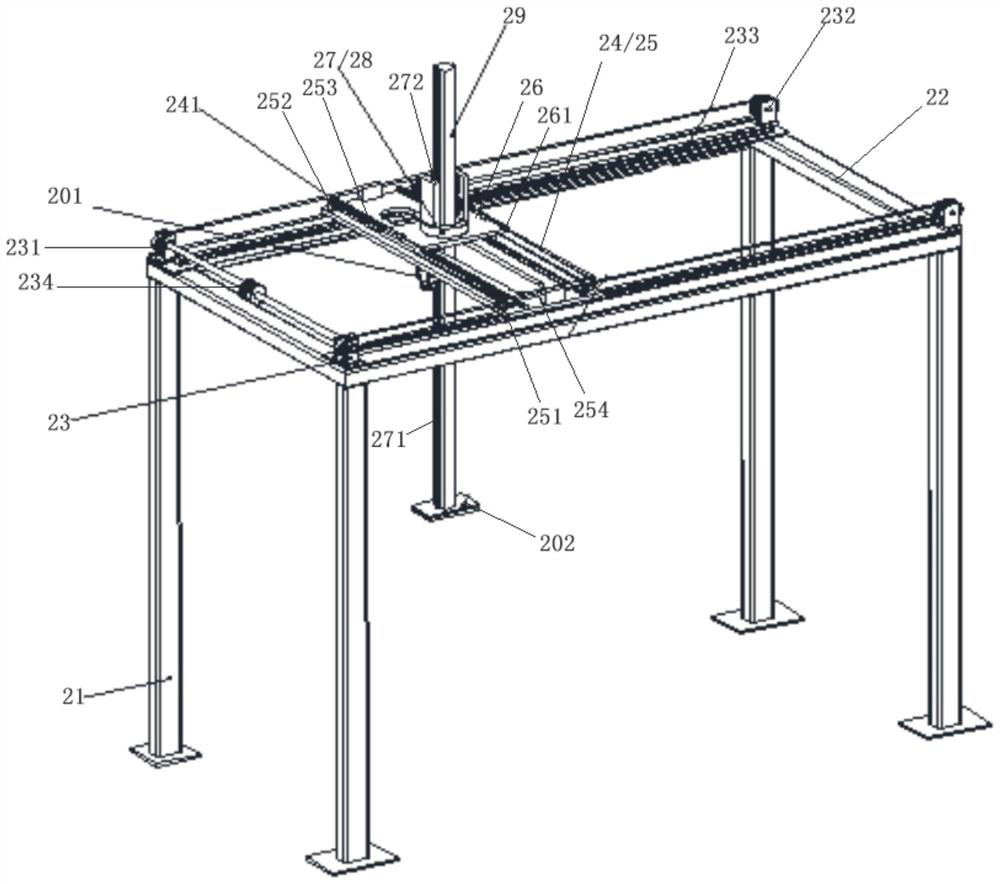

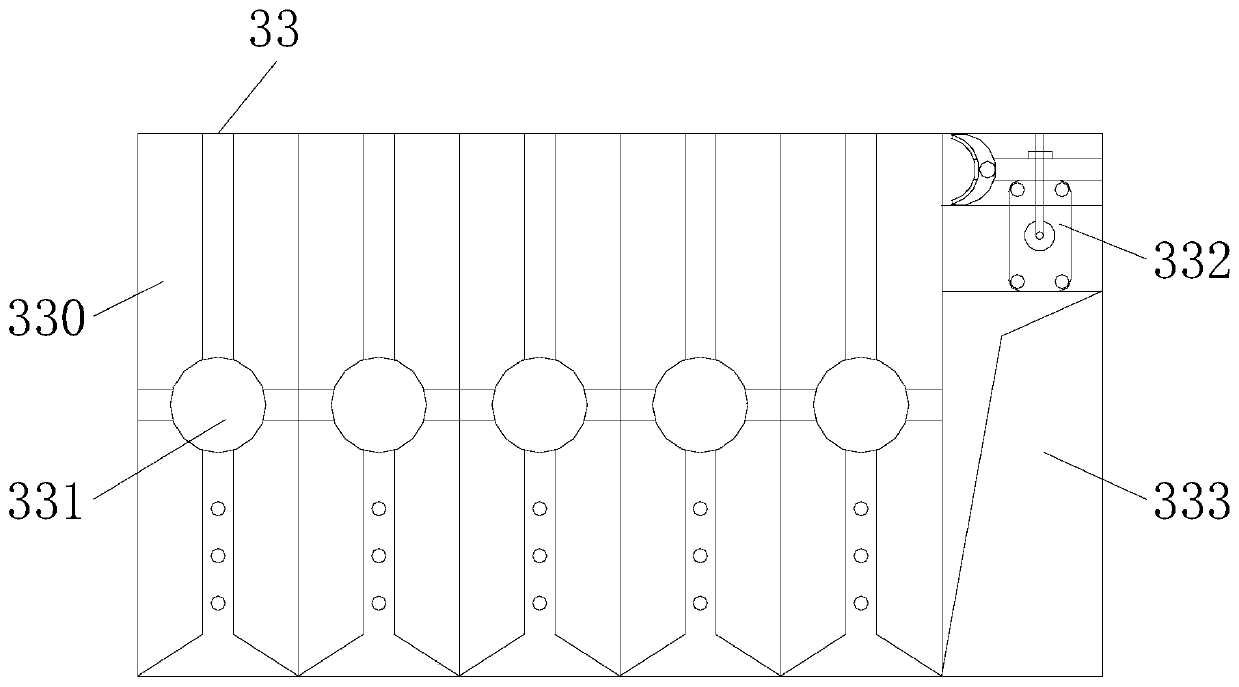

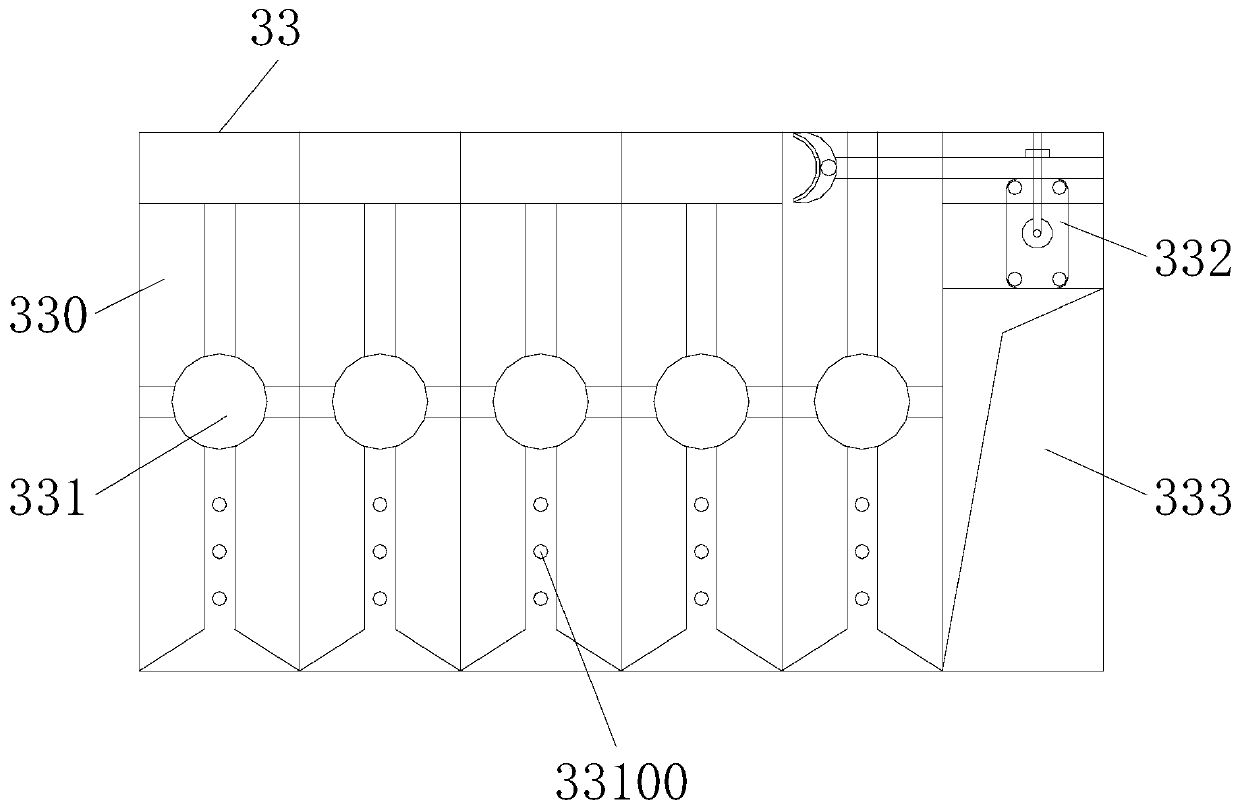

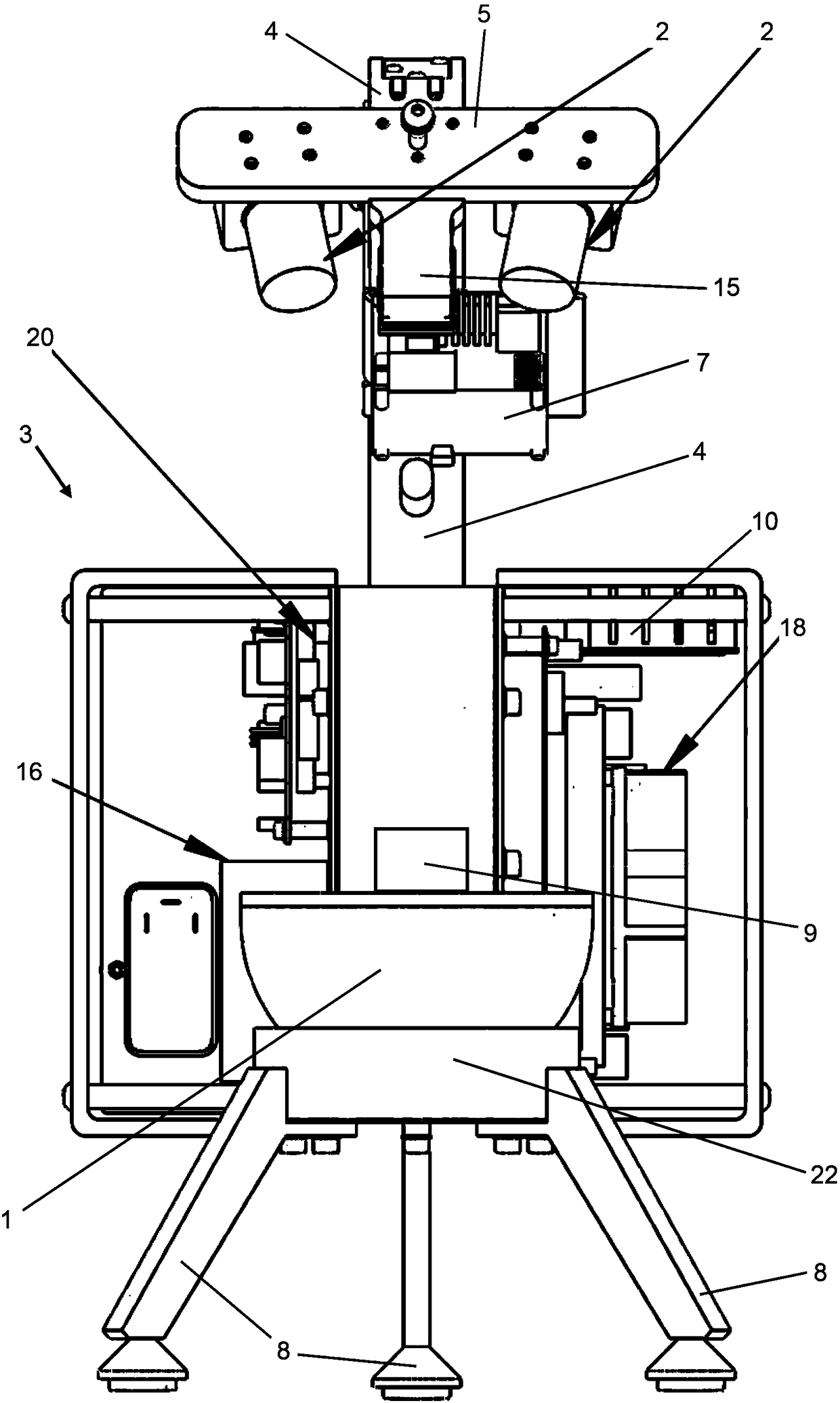

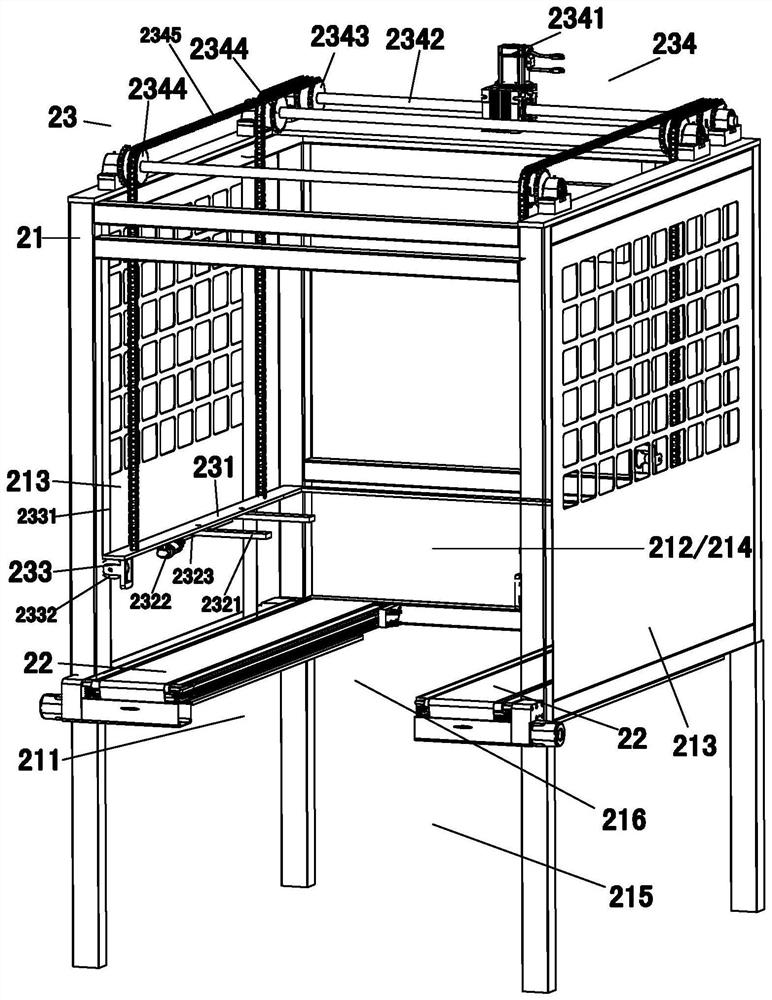

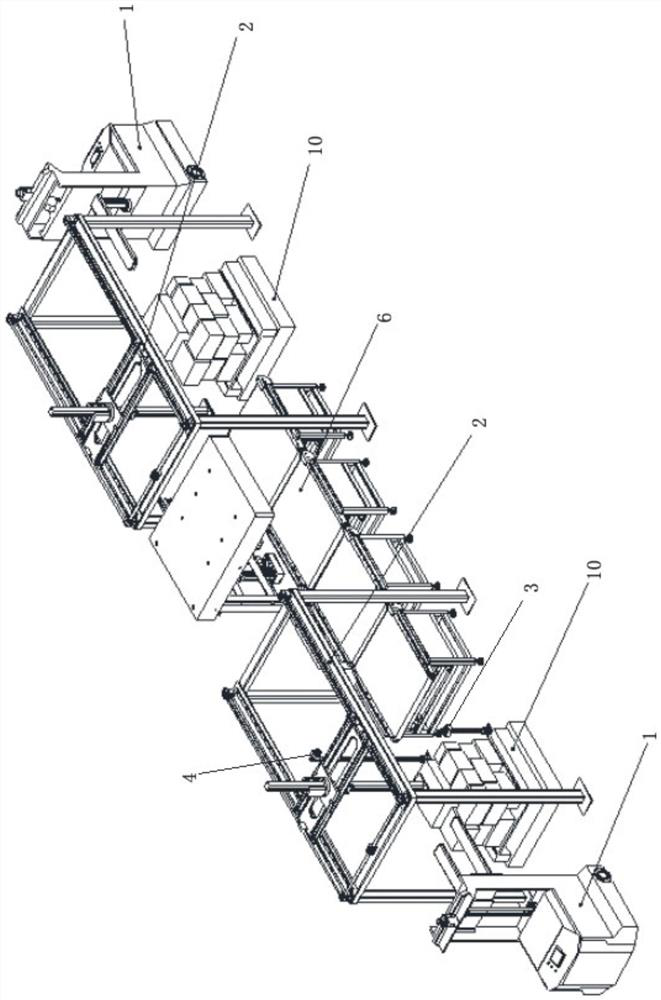

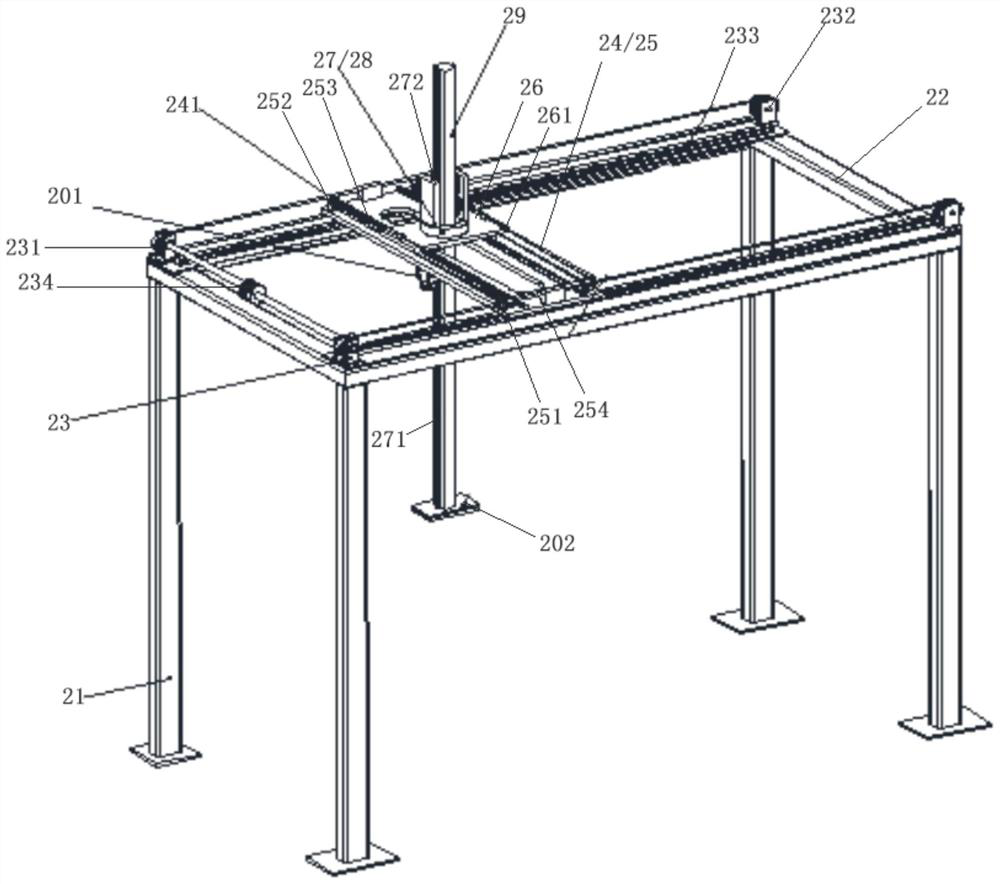

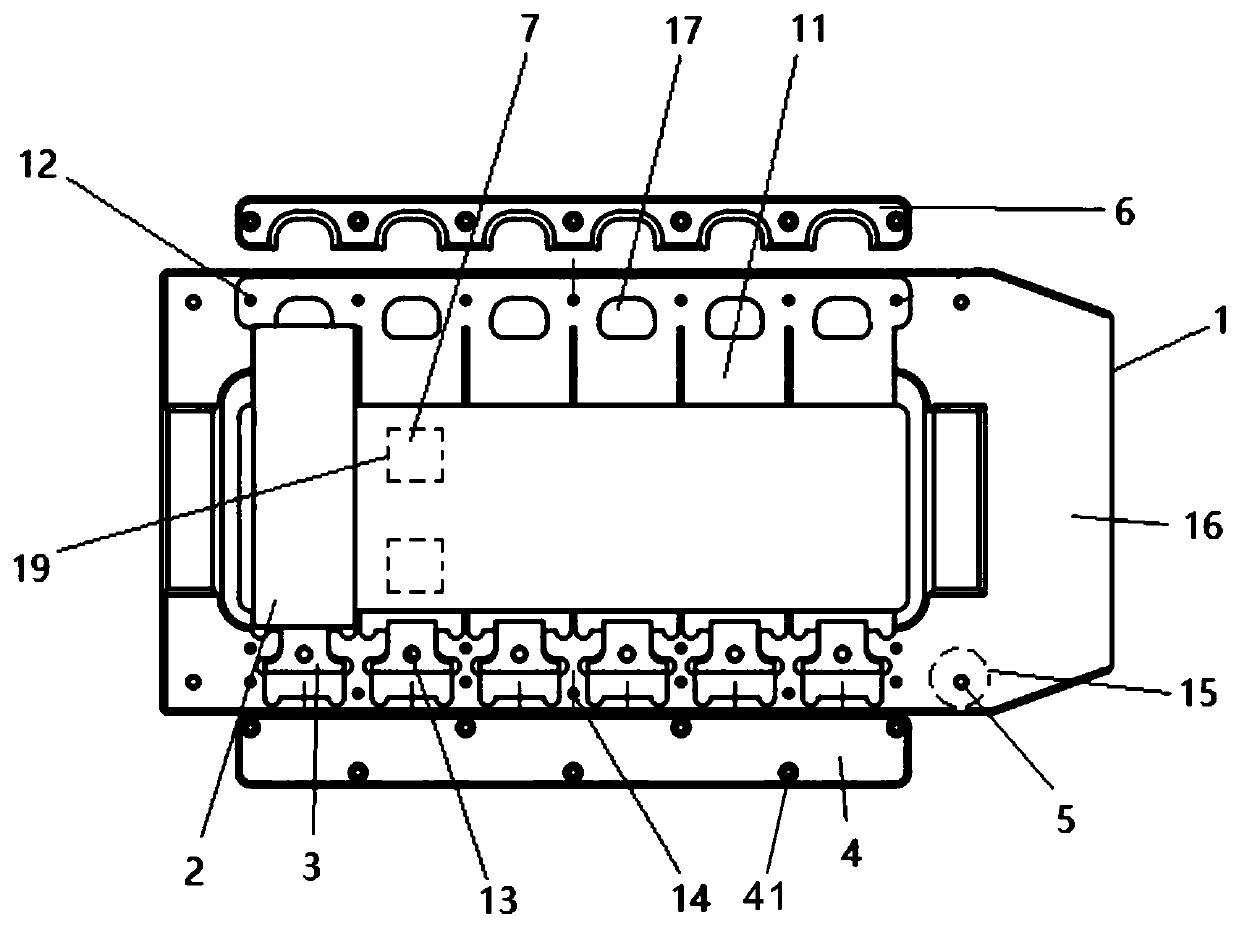

Automatic rapid batch code scanning assembly line for small express items and processing method thereof

ActiveCN112093442ACompact structureEasy to useImage analysisGeometric image transformationControl systemProcess engineering

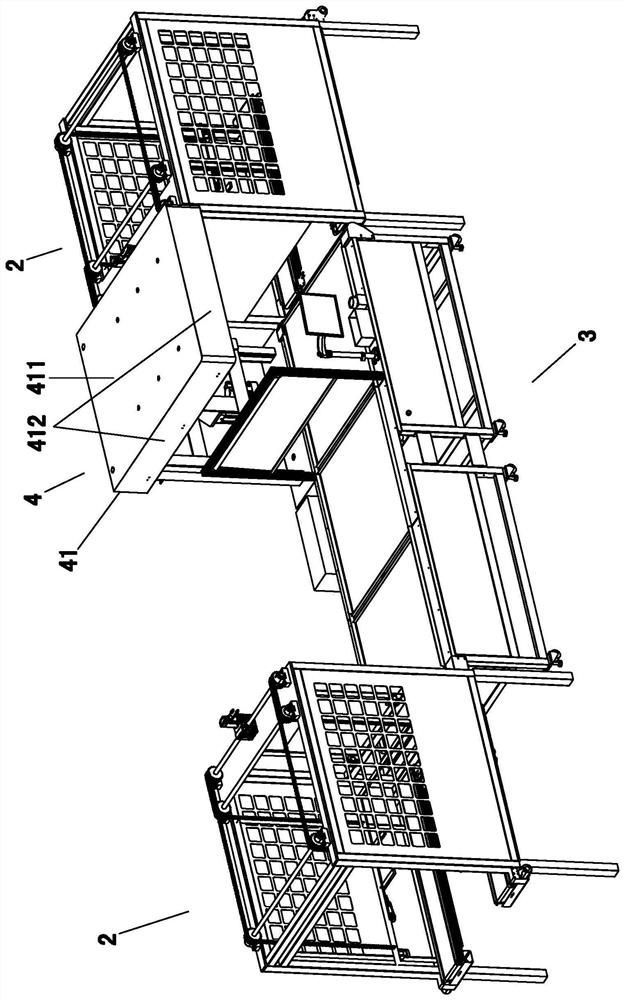

The invention discloses an automatic rapid batch code scanning assembly line for small express items and a processing method thereof. The automatic rapid batch code scanning assembly line comprises anautomatic transport vehicle, tray feeders, a conveying line, a batch code scanning machine and a control system; the batch code scanning machine comprises a camera mounting framework which is correspondingly arranged above the output end of the conveying line and a supporting connecting device which is arranged on the side edge of the conveying line and is connected with the camera mounting framein a supporting mode; the automatic transport vehicle is used for bearing and transporting a stacking tray fed into or output from the tray feeder; the automatic transport vehicle is provided with alifting material supporting bearing platform used for erecting the stacking tray; and the control system controls work operation and code scanning recognition control of the whole machine. The assembly line is high in automation level, high in work efficiency, compact in mechanical structure and stable in work.

Owner:SF TECH +1

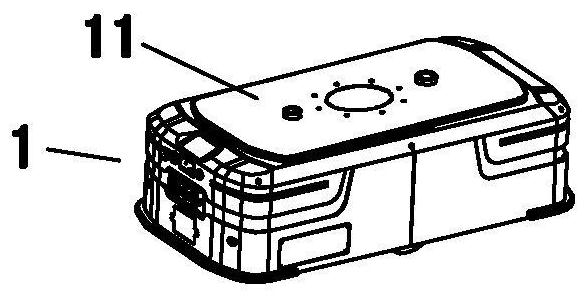

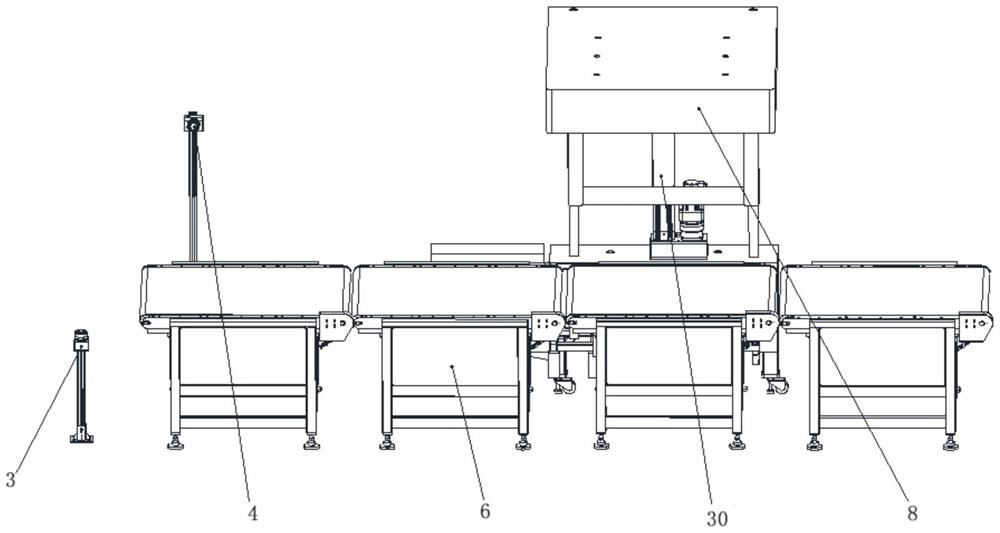

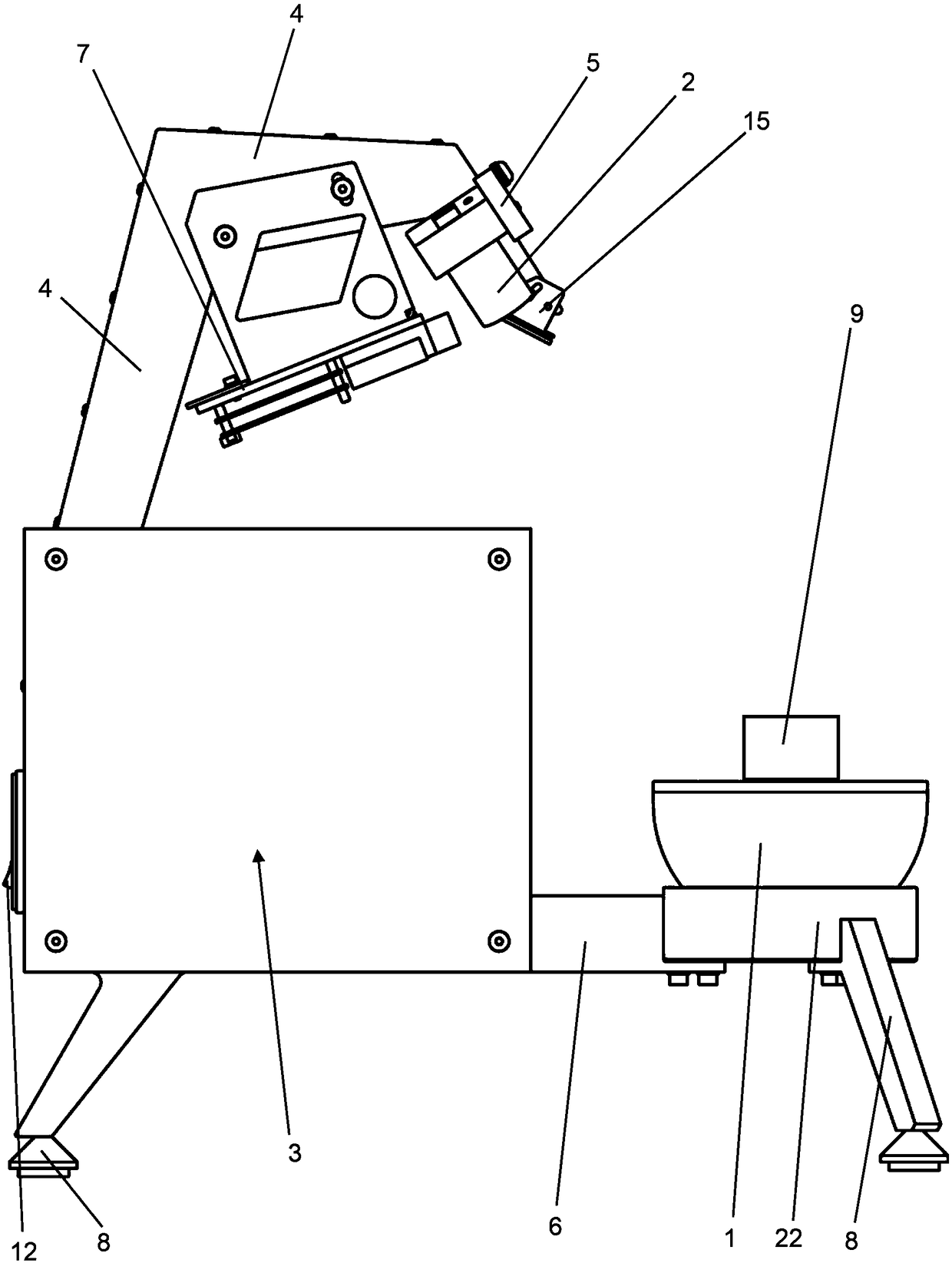

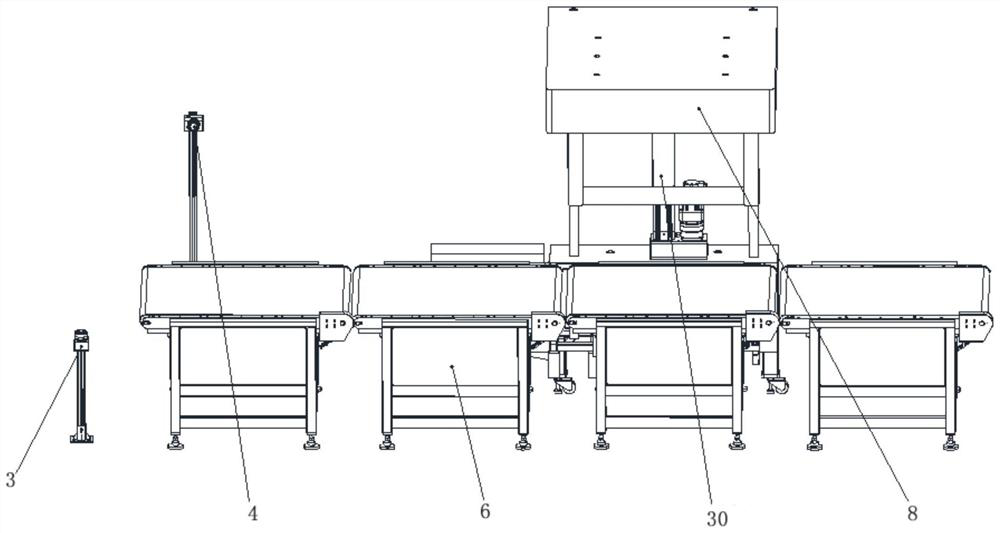

Express full-automatic multi-surface code scanning, weighing and volume measuring system and processing method thereof

ActiveCN112179272AReduce investmentSave operating timeUsing optical meansStacking articlesControl systemEngineering

The invention relates to the field of express full-automatic code scanning and measuring systems, and particularly discloses an express full-automatic multi-surface code scanning, weighing and volumemeasuring system and a processing method thereof, and the system comprises an automatic transportation forklift, multi-axis manipulators, a bottom surface code scanning camera, a side surface code scanning camera, a top surface code scanning and volume measuring camera, a code scanning and weighing conveying line and a control system. The multi-axis manipulators are arranged at the two ends of thecode scanning and weighing conveying line respectively, the automatic transportation forklift is used for conveying stacking trays for stacking express items, the bottom surface code scanning camerais arranged below the working end movement range of the multi-axis manipulators, and the side surface code scanning camera is arranged corresponding to the side edge of the working end movement rangeof the multi-axis manipulators. The top surface code scanning and volume measuring camera is correspondingly arranged above the code scanning and weighing conveying line, the control system controls work and operation of the whole machine, and a gravity sensor is arranged on the code scanning and weighing conveying line. According to the system, a traditional conveying method is changed, automaticexpress item processing such as multi-face code scanning, weighing and volume measuring is achieved, the working efficiency is high, the mechanical structure is compact, and work is stable.

Owner:SF TECH +1

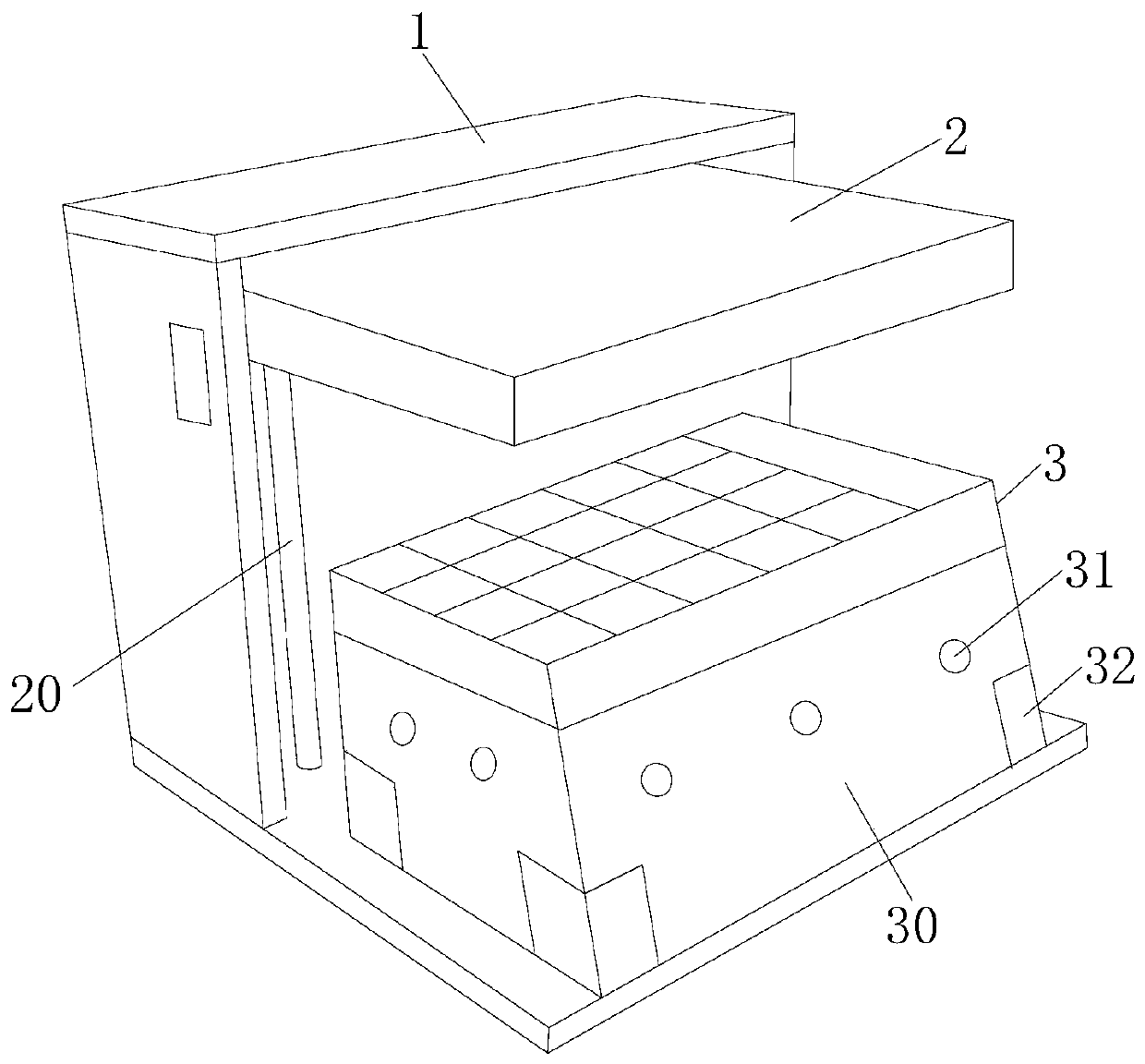

Wafer flow sheet surface flatness detection device capable of avoiding false flaws

ActiveCN110021534AEasy to process and scanThe scanning distance is shortenedSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingTest frameAssembly line

The invention discloses a wafer flow sheet surface flatness detection device capable of avoiding false flaws. The wafer flow sheet surface flatness detection device structurally comprises a test frame, a scanning plate and a conveying table; the test frame is in track connection with the scanning plate; the scanning plate is in threaded connection with a threaded rod, and the threaded rod is arranged on the test frame; the test frame is locked with the conveying table; the conveying table is composed of a surrounding frame, a lock hole, a lock plate and an internal device; the surrounding frame is provided with the lock hole and the lock plate; the internal device is arranged on the surrounding frame; when the wafer is in assembly line processing and passes through a detection device, thescanning plate is adopted for scanning detection; if the products are qualified products, the qualified products are continuously conveyed to the next procedure on the conveying table; and if defective products are detected, the internal device operates, and secondary scanning detection is carried out by the internal scanning device; the side scanning of the internal scanning device can judge whether the flaws are pseudo flaws or not more accurately, so that secondary overhauling of qualified products is avoided, the processing cost is lowered, and the production efficiency is improved.

Owner:SHENZHEN SMARTMORE TECH CO LTD +1

Equipment for automatically scanning bar codes of commodities

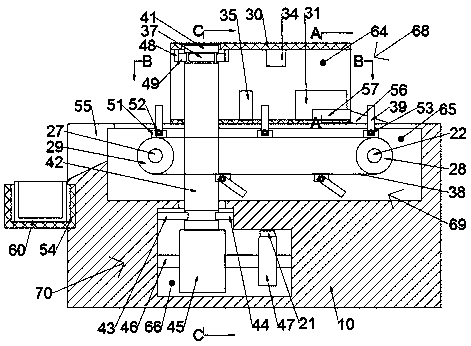

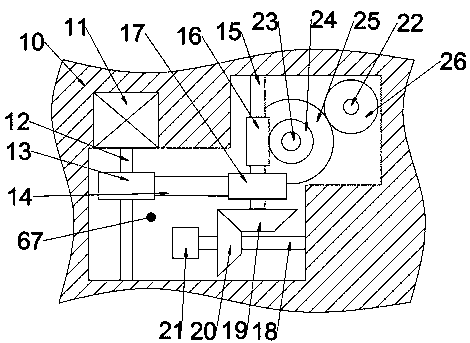

ActiveCN111126094AReduce laborImprove scan accuracySensing by electromagnetic radiationBarcodeEngineering

The invention discloses equipment for automatically scanning bar codes of commodities. The equipment comprises a machine body, a conveying cavity 65 is formed in the machine body 10, a rotary cavity 66 is formed in the lower side of the conveying cavity 65, a code-scanning housing 30 is fixedly arranged on the upper side surface of the machine body 10, a scanning cavity 64 is formed in the code-scanning housing 30, a transmission cavity 67 is formed in the rear side of the conveying cavity 65, and a scanning device 68 for scanning commodities is arranged in the scanning cavity 64. The equipment can automatically convey and scan the commodities, increase the scanning speed, increase the scanning efficiency, shorten the waiting time of people and reduce the labor amount of workers.

Owner:诸暨迅超工业设计有限公司

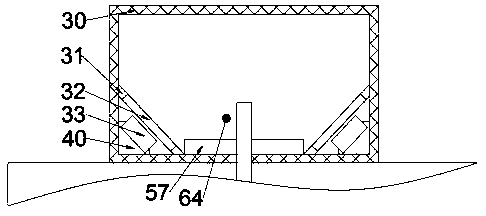

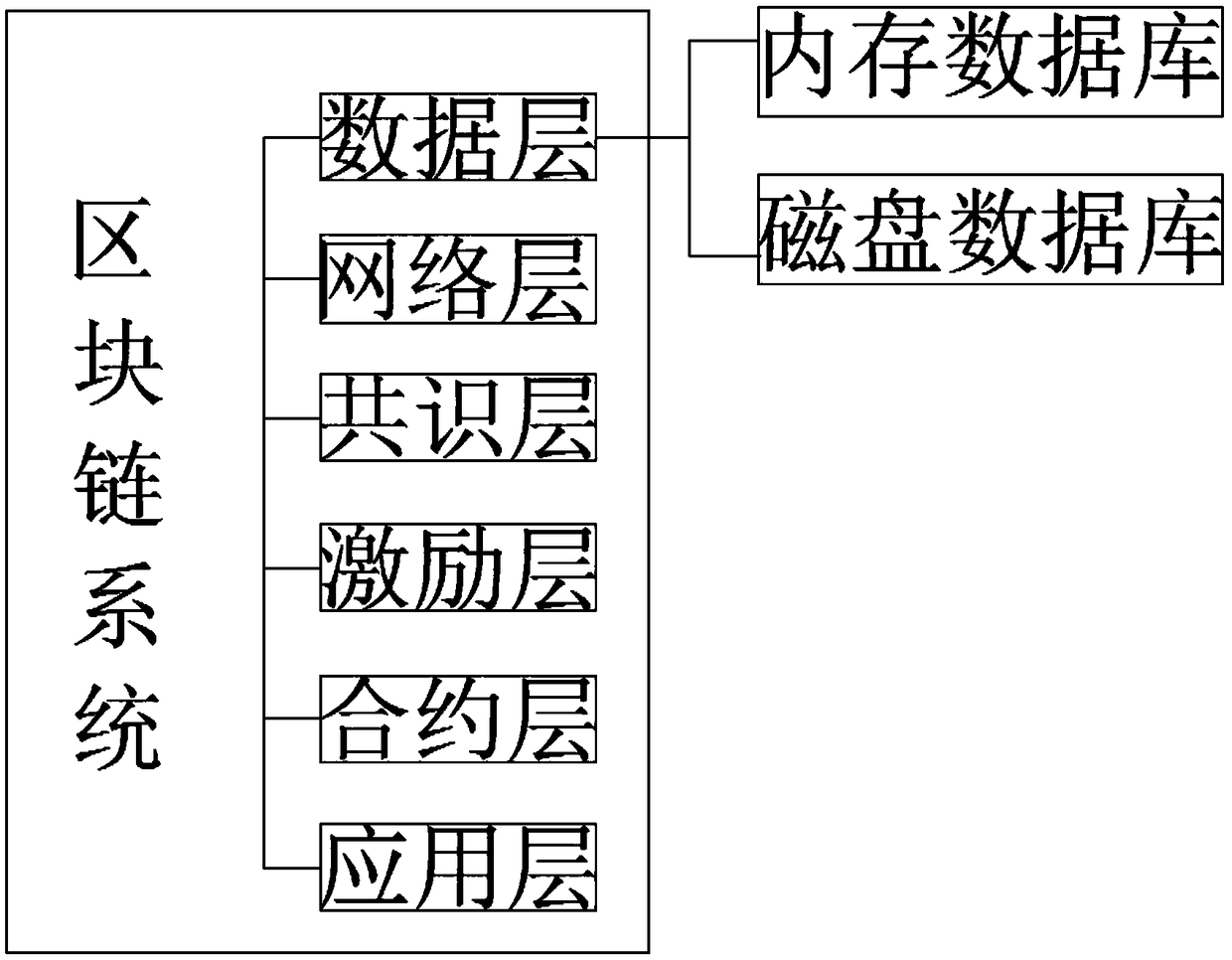

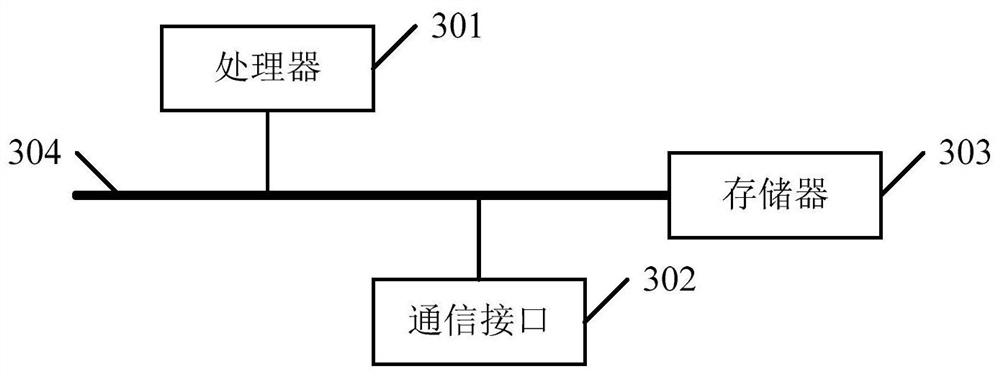

An anti-falling code scanning device based on the block chain technology

InactiveCN109376561AImprove scan accuracyAvoid damageSensing by electromagnetic radiationMechanical engineeringPiston

The invention relates to an anti-falling code scanning device based on the block chain technology The device includes a main body and an acquisition screen. A processor and a memory are arranged in the main body, A fixing mechanism is arranged in the main body; the fixing mechanism includes a drive assembly, a movable plate and two stationary assemblies; the fixing assembly includes an air suctionrod, a suction cylinder, a piston, connecting tubes and suction cups; a shield mechanism is arranged on that main body; the shielding mechanism includes a rotating assembly, two transmission assemblies and two lifting assemblies; the rotating assembly includes a shield box, A rotating shaft, a shielding cloth and a connetion rod are arranged in the shielding box, The anti-falling code sweeping device based on block chain technology can cover the collecting screen when the code sweeping device is idle, thereby reducing the probability of misoperation and avoiding dust covering on the collecting screen. The code sweeping device and the desktop can be fixed by the fixing mechanism to prevent the code sweeping device from falling and being damaged.

Owner:SHENZHEN XIAOKONG COMM TECH CO LTD

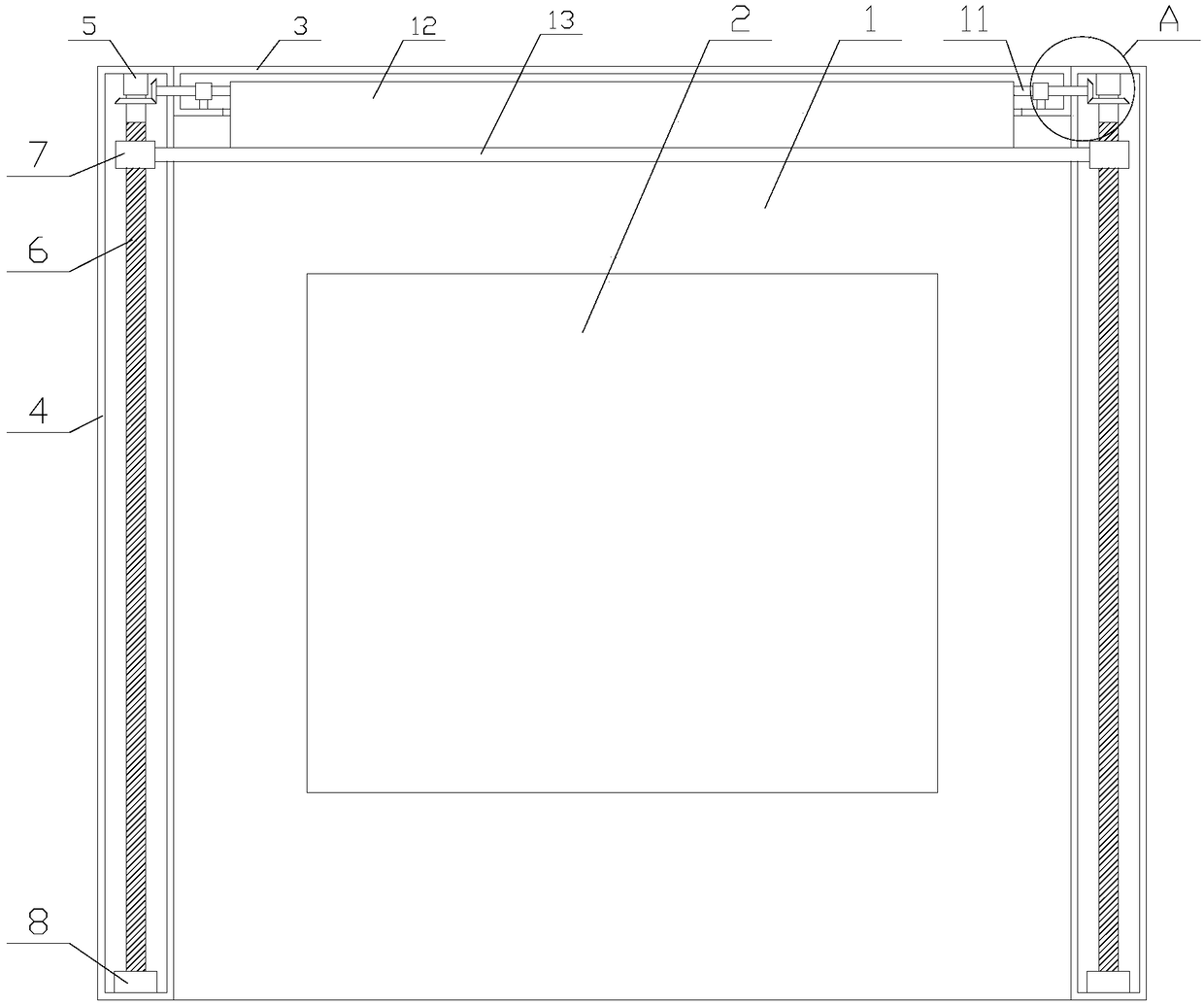

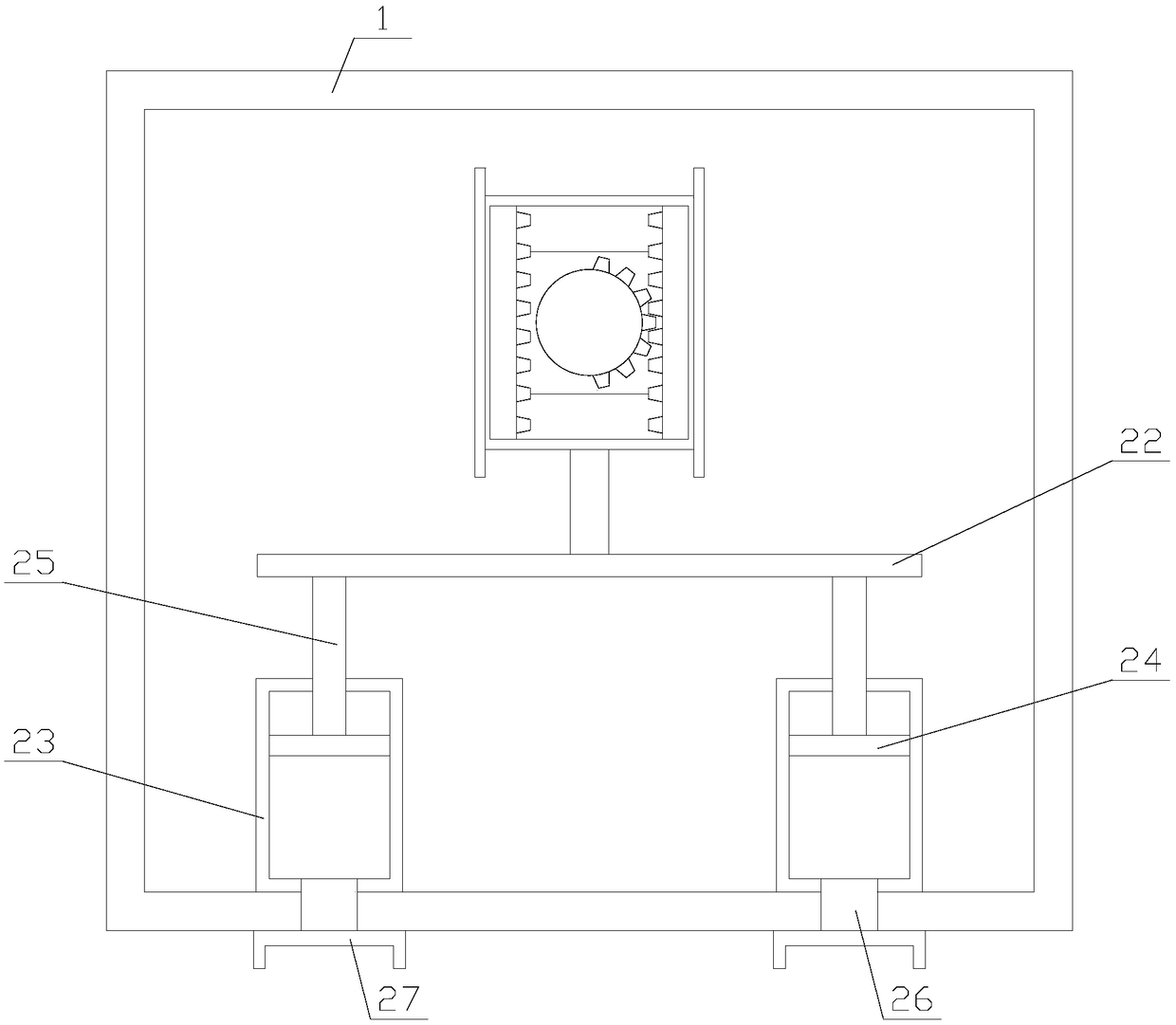

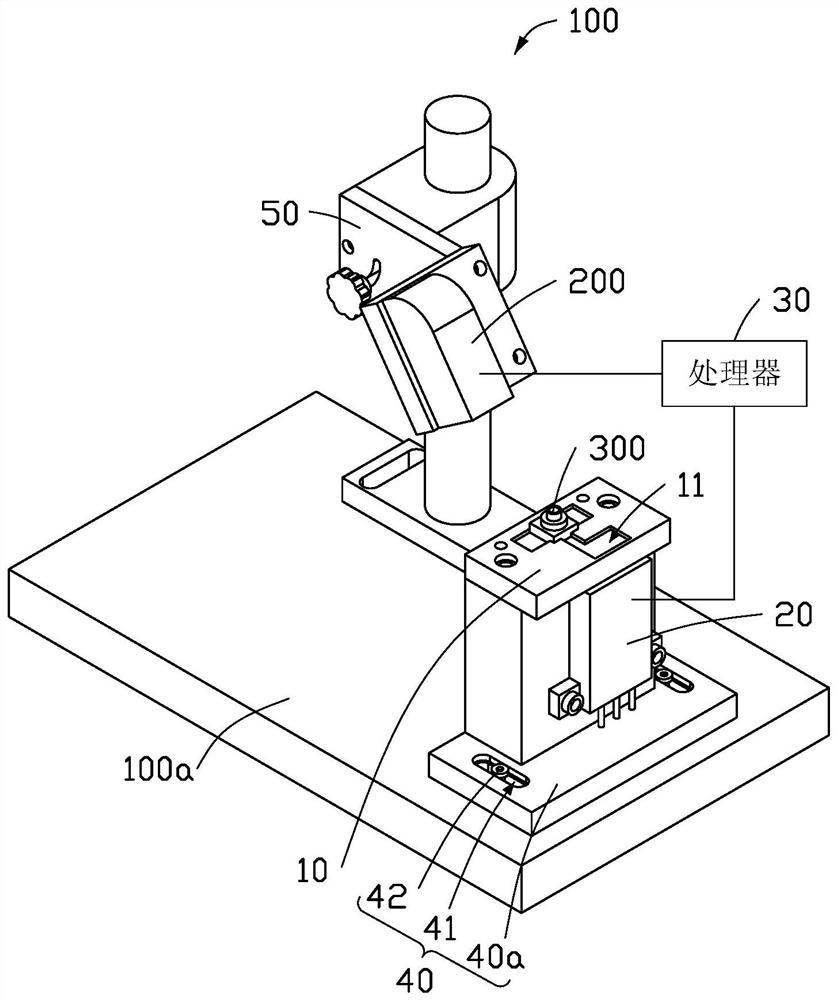

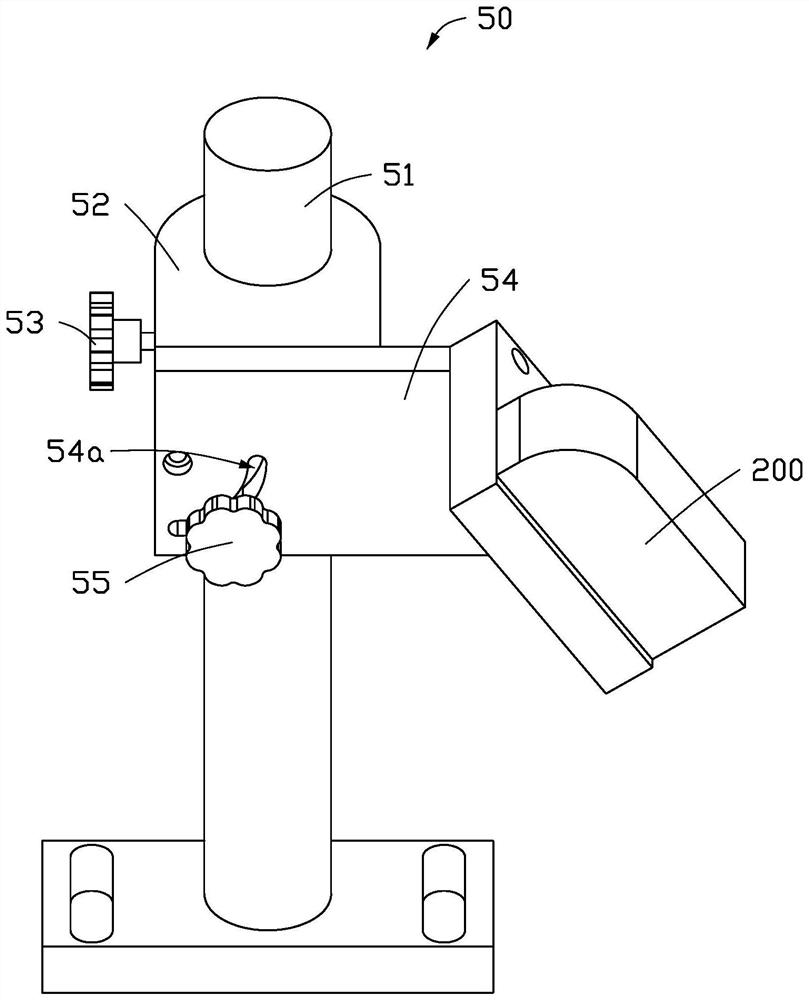

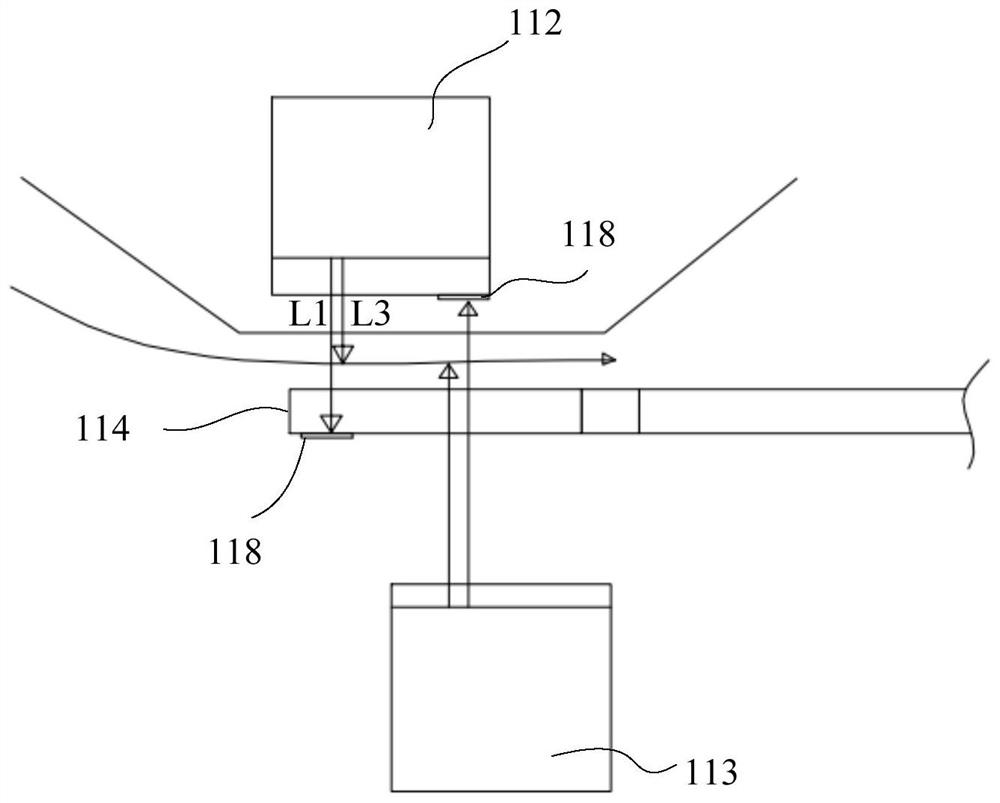

Three-dimensional scanning device and control method thereof

ActiveCN108775873ASimple and reasonable designImprove Scanning AccuracyUsing optical meansThree dimensional modelEngineering

Owner:ZHEJIANG SHUREN UNIV

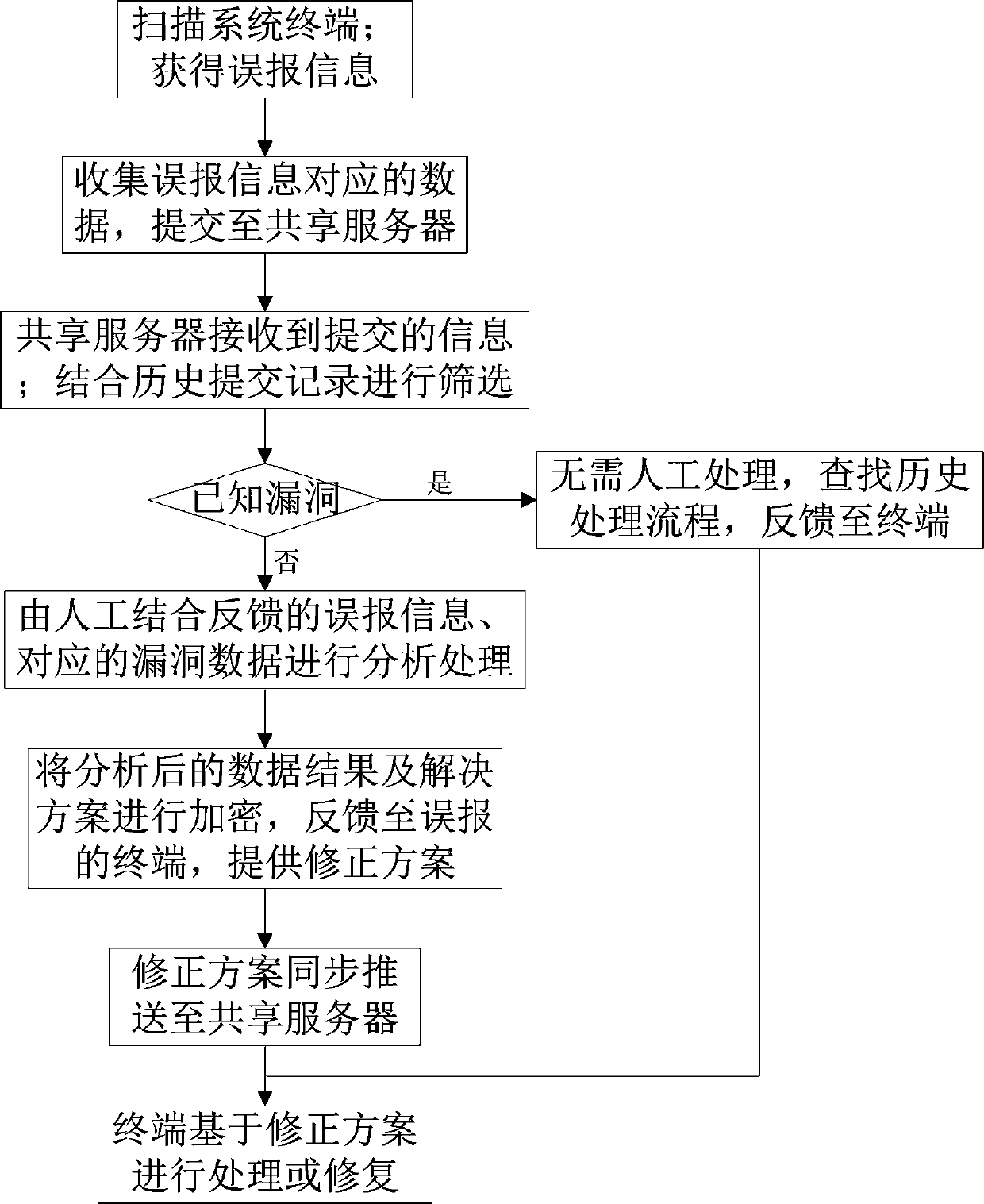

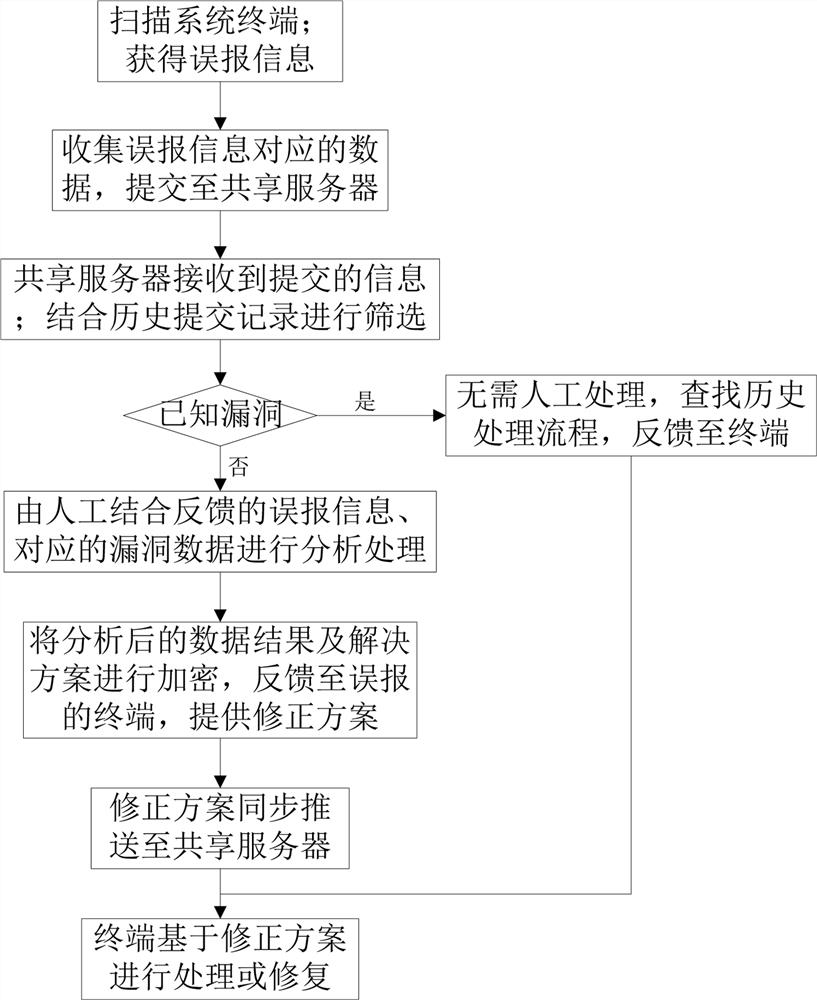

Method for reducing false alarm of vulnerability scanning

ActiveCN110753047AReduce false alarm rateReduce follow-up workloadPlatform integrity maintainanceTransmissionData setData mining

The invention relates to a method for reducing the false alarm of vulnerability scanning. The method comprises the following steps of: obtaining false alarm information and corresponding data by scanning a system terminal, submitting the false alarm information and the corresponding data to a shared server for manual auditing and affirmation, adjusting technical parameters, providing and synchronizing a correction scheme, and finally processing or repairing by the terminal based on the correction scheme. According to the invention, vulnerability types with high false alarm rate can be marked in a unified manner; determining a false alarm point, refining the collected false alarm items, then performing content analysis processing and refining in a unified manner, performing professional analysis on the collected false alarm content by a technician, performing misjudgment and corresponding correction, and performing correction processing on a database and a vulnerability library; data centralized processing and updating optimization processing are adopted to solve false alarm, the detection efficiency is improved, effective false alarm related data can be collected, the subsequent workload is reduced, qualitative improvement is brought to vulnerability scanning accuracy, the false alarm rate is reduced, and repeated work is greatly reduced.

Owner:HANGZHOU ANHENG INFORMATION TECH CO LTD

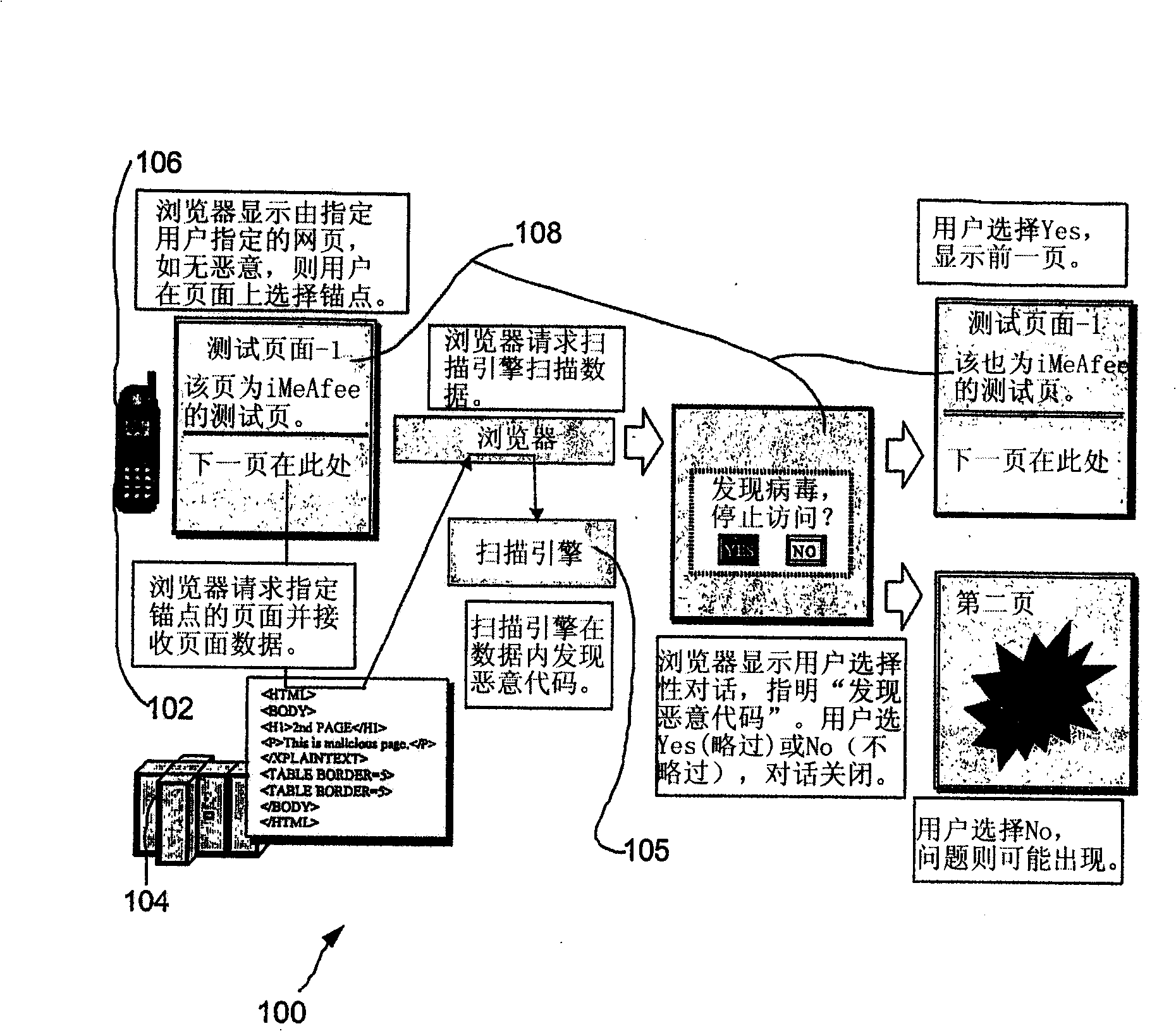

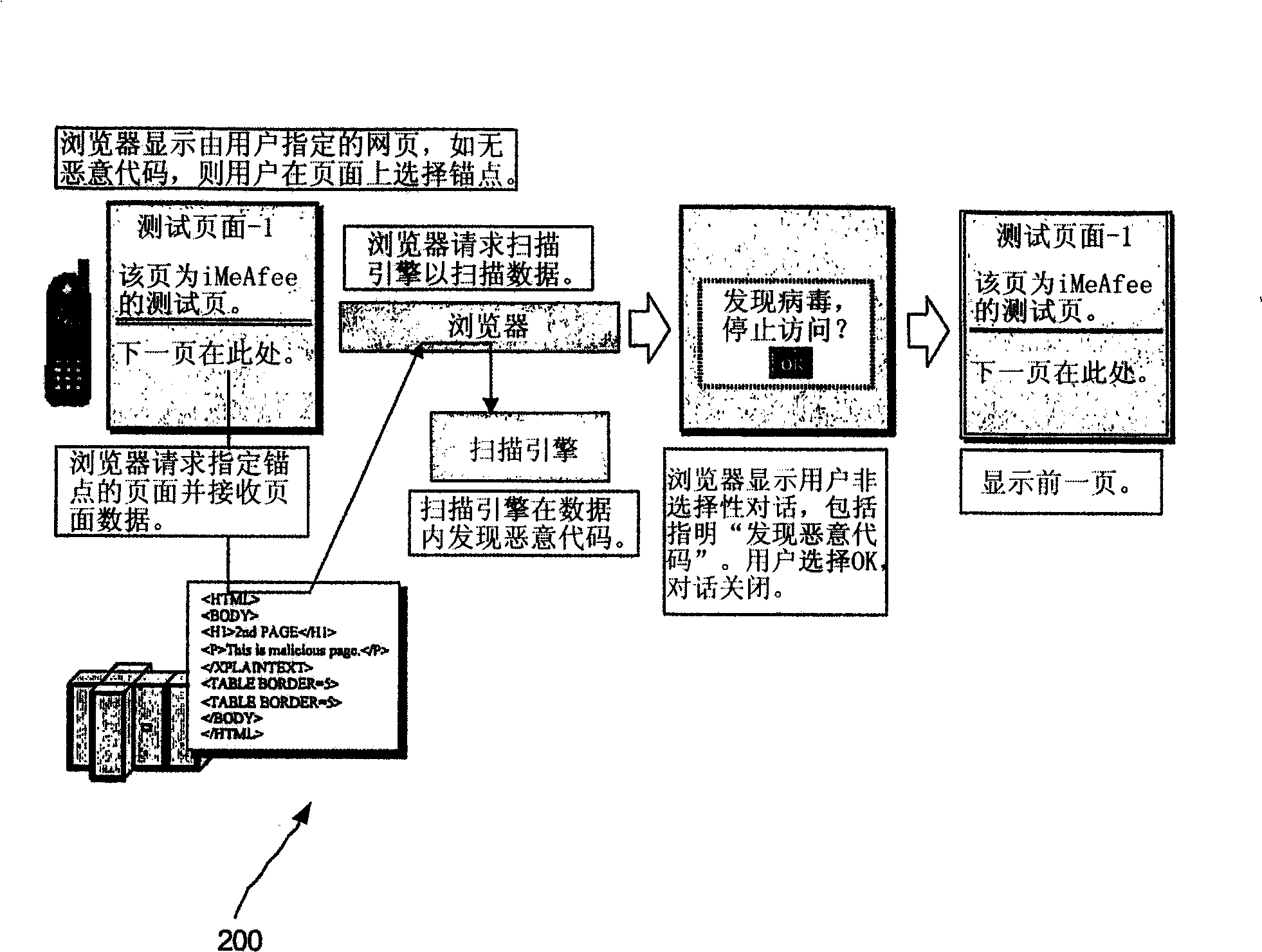

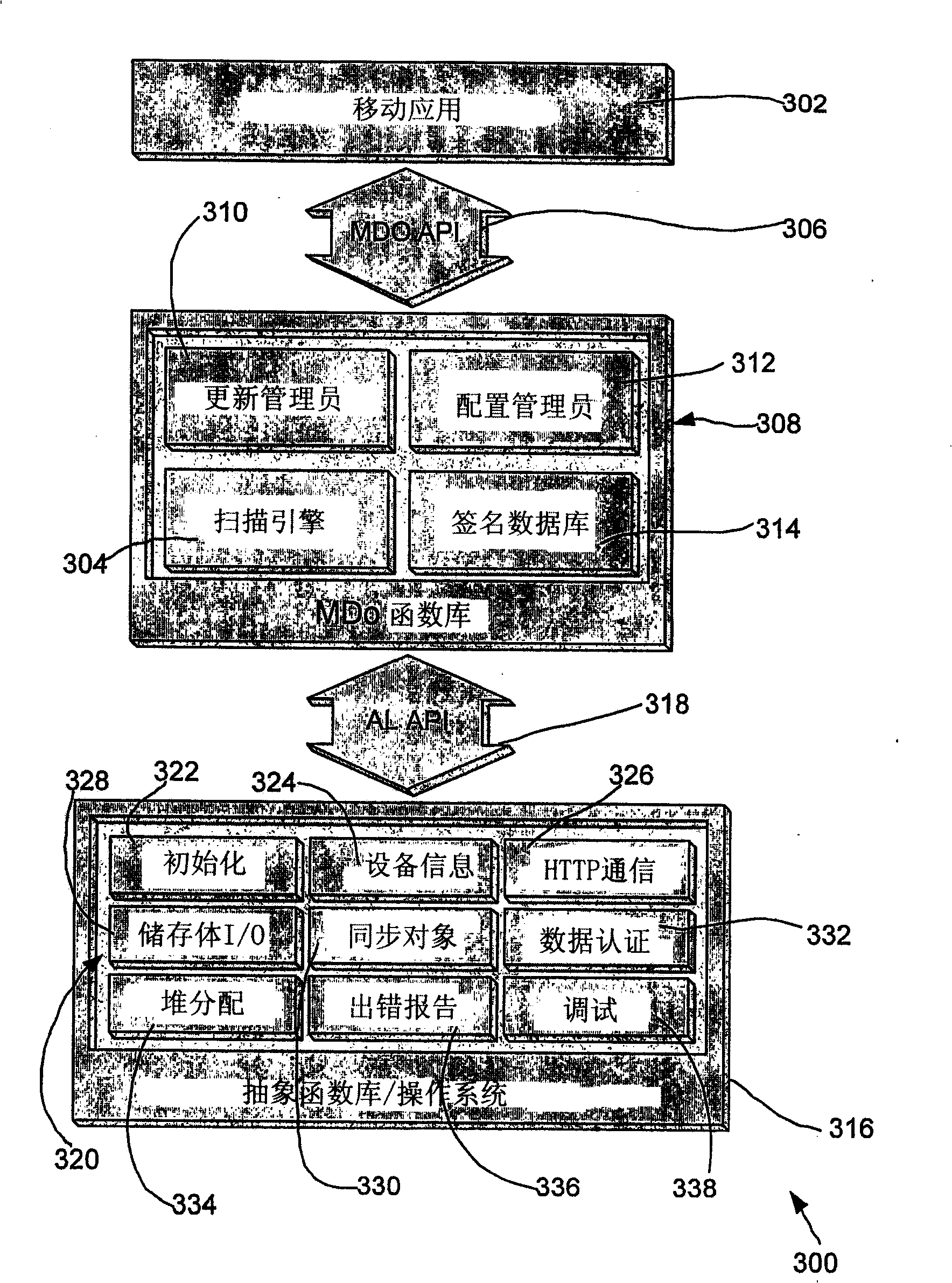

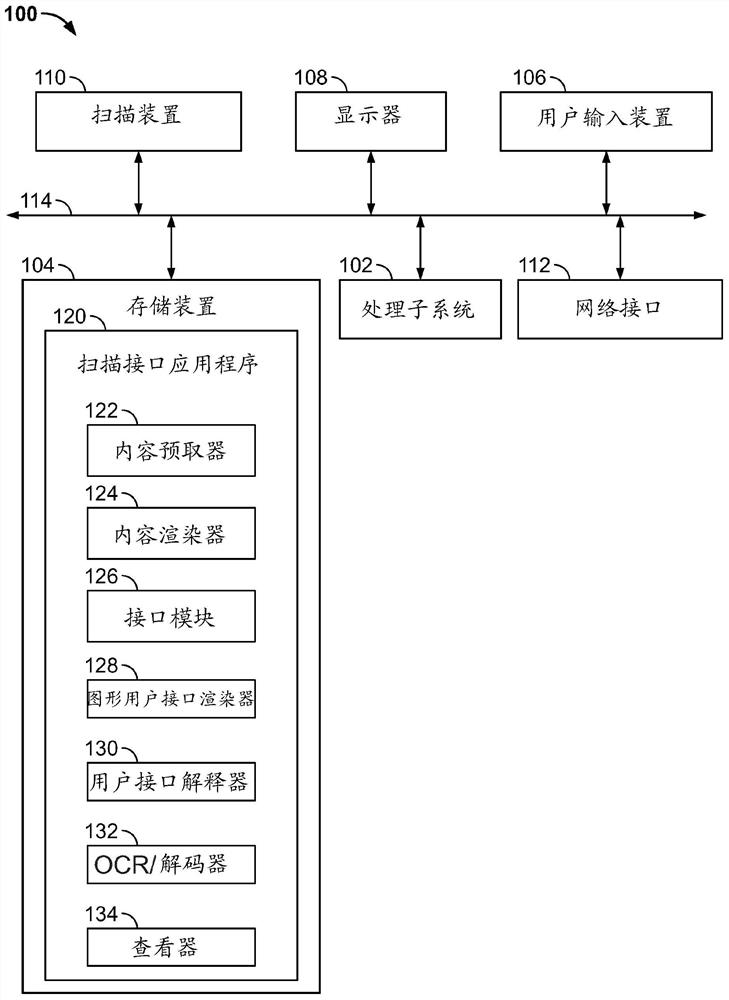

System, method and computer program product for content/context sensitive scanning utilizing a mobile communication device

ActiveCN101248427AImprove scan timeImprove scan accuracyUser identity/authority verificationDigital computer detailsApplication programming interfaceNetwork communication

A platform independent system for a mobile communication device and methods related thereto are provided. A mobile communication device capable of communicating over a wireless network is included. The mobile communication device is installed with an operating system. Associated with it is a platform-independent scanning subsystem that communicates with the operating system on the mobile communication device for scanning purposes. A platform-independent API is also provided for interfacing the operating system and scanning subsystem. The platform-independent application programming interface includes an abstraction library that acts as a port to install the platform-independent scanning subsystem to the mobile communication device and its associated operating system.

Owner:MCAFEE INC +1

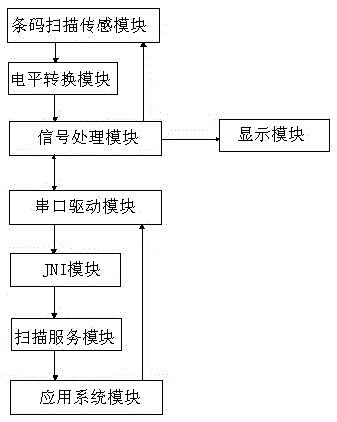

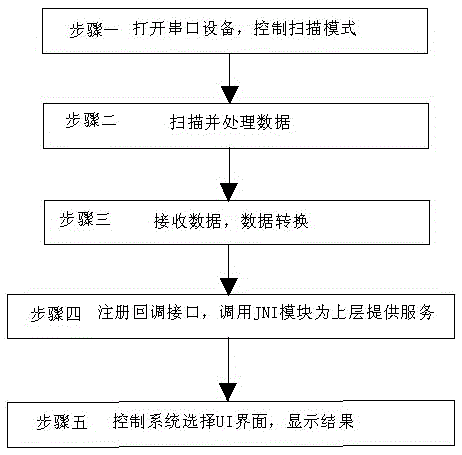

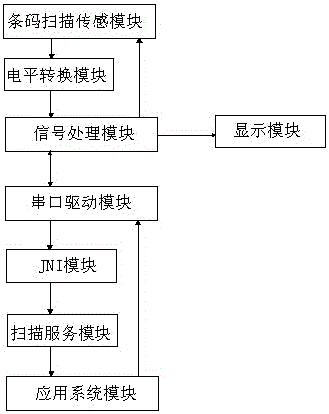

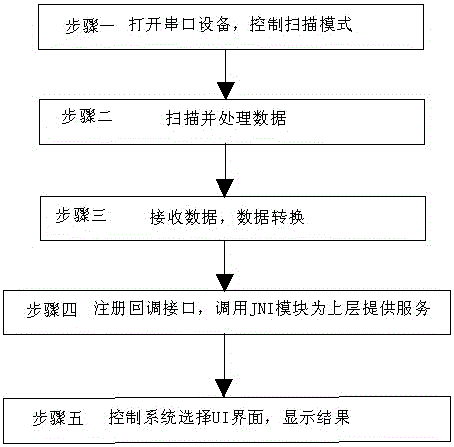

Laser barcode scanning system and method based on mobile intelligent terminal

ActiveCN105550621AImprove scan accuracyScan code error rate is zeroSensing by electromagnetic radiationControl systemBarcode

The invention discloses a laser barcode scanning system and method based on a mobile intelligent terminal, and belongs to the technical field of laser barcode scanning. The system comprises a barcode scanning sensing module, a level conversion module, a signal processing module, a serial port driving module, a JNI (Java Native Interface) module, a scanning service module, an application system module and a display module. The method comprises the following steps: 1) starting serial port equipment, and controlling a scanning mode; 2) scanning and processing data; 3) receiving the data, and carrying out data conversion; 4) registering a callback interface, and calling the JNI module to provide a service interface for an upper-layer application; and 5) controlling the system to select a UI (User Interface) display way, and displaying a result. The laser barcode scanning system and method are completely realized on the basis of the mobile intelligent terminal, scanning accuracy is improved, scanning is not restricted by environment, barcode scanning speed is quickened, and the equipment is convenient in carrying, is small and portable and is especially suitable for occasions of mobile office.

Owner:JIANGSU ZHILIAN TIANDI TECHNOLOGY CO LTD

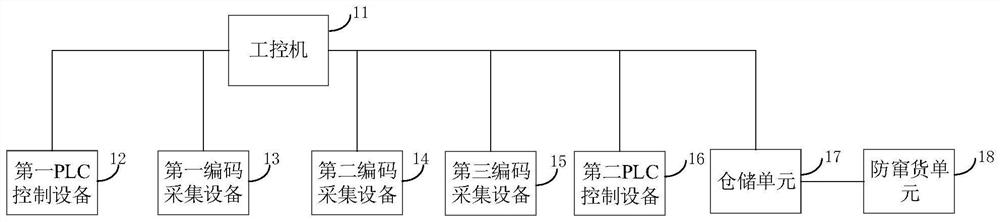

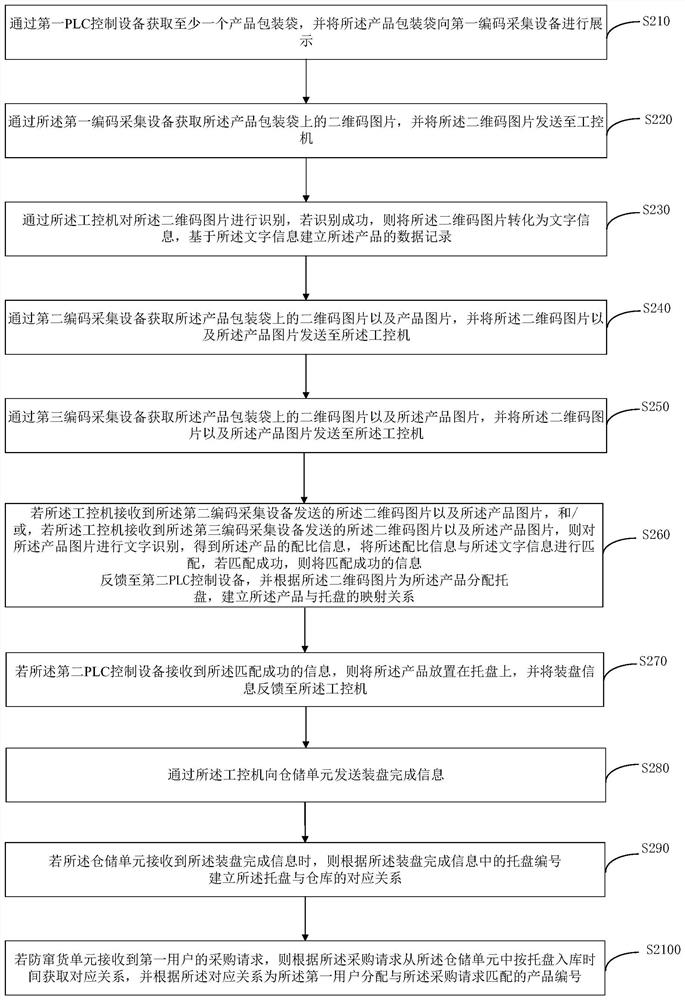

Production, storage and logistics integrated system and method

PendingCN113837339ARealize traceabilityImprove scan accuracyCo-operative working arrangementsLogisticsInformatizationLogistics management

The embodiment of the invention discloses a production, storage and logistics integrated system and a method. The system comprises a first code collection device used for collecting a two-dimensional code picture on a product packaging bag and sending the two-dimensional code picture to an industrial personal computer; an industrial personal computer is used for feeding back a successful recognition result to the first PLC control equipment if the two-dimensional code picture is recognized successfully; a second code collection equipment is used for sending the two-dimensional code picture and the product picture to the industrial personal computer; the industrial personal computer is also used for feeding back information indicating that the matching information is successfully matched with the character information to the second PLC control equipment; the second PLC control equipment is used for placing the product on the tray and feeding back the tray loading information to the industrial personal computer if the matching success information is received; and the industrial personal computer is further used for sending tray loading completion information to the storage unit. By executing the scheme, the code scanning accuracy can be improved, informatization management can be performed on the product, the product can be traced, the labor cost is saved, and the management efficiency is improved.

Owner:CHINA NAT OFFSHORE OIL CORP

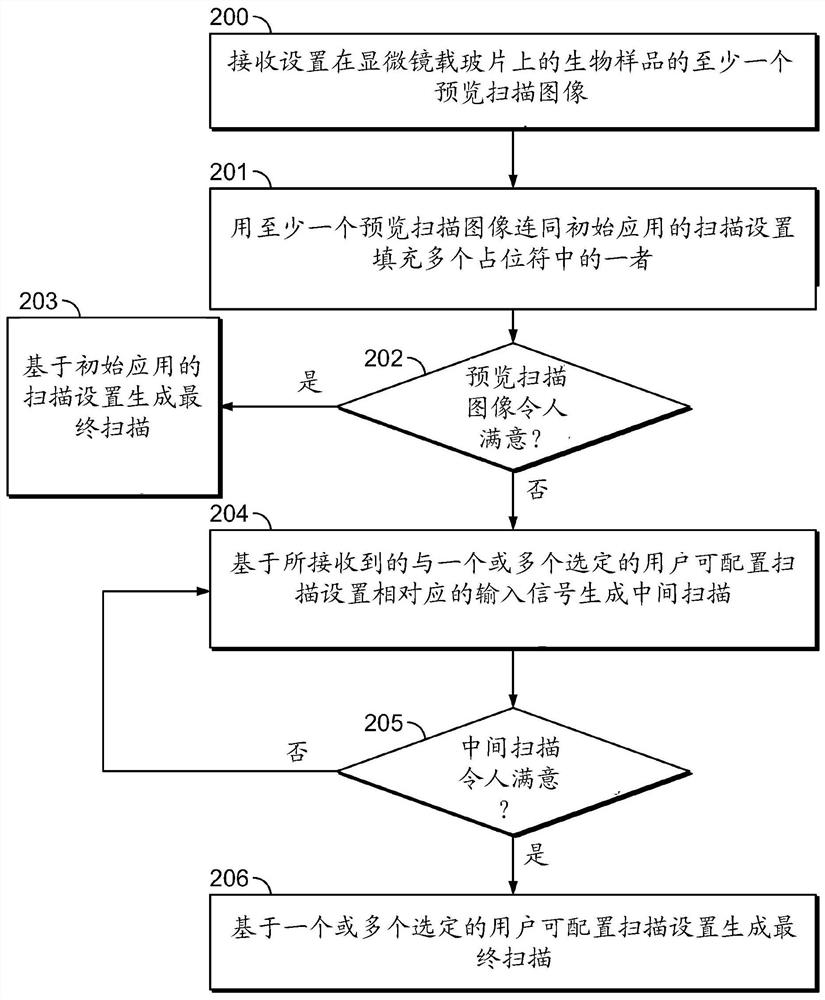

Digital pathology scanning interface and workflow

PendingCN111868833AEffective and Accurate ScanningImprove collection efficiencyMicroscopesMedical imagesGraphicsGraphical user interface

Disclosed herein is a method of acquiring a high-resolution scan of a biological sample disposed on a substrate with a scanning device, the method comprising: receiving, on a graphical user interface,a first user input corresponding to user configurable scanning settings; receiving, on a graphical user interface, a second user input to initiate scanning based on the received series of user inputscorresponding to user configurable scanning settings; and displaying, on the graphical user interface, a visualization of one or more placeholders populated with one or more of scanning operation status information, image data, and at least a portion of the user configurable scanning settings.

Owner:VENTANA MEDICAL SYST INC

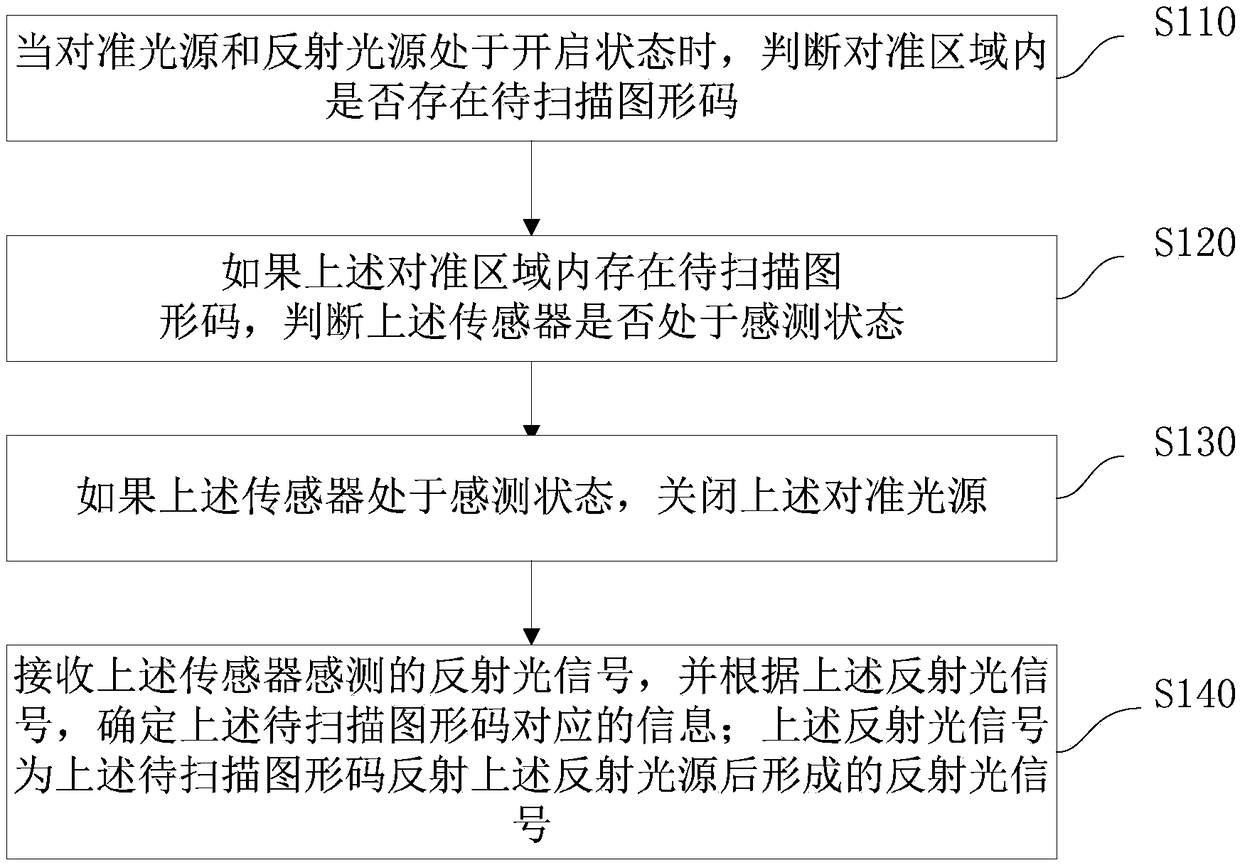

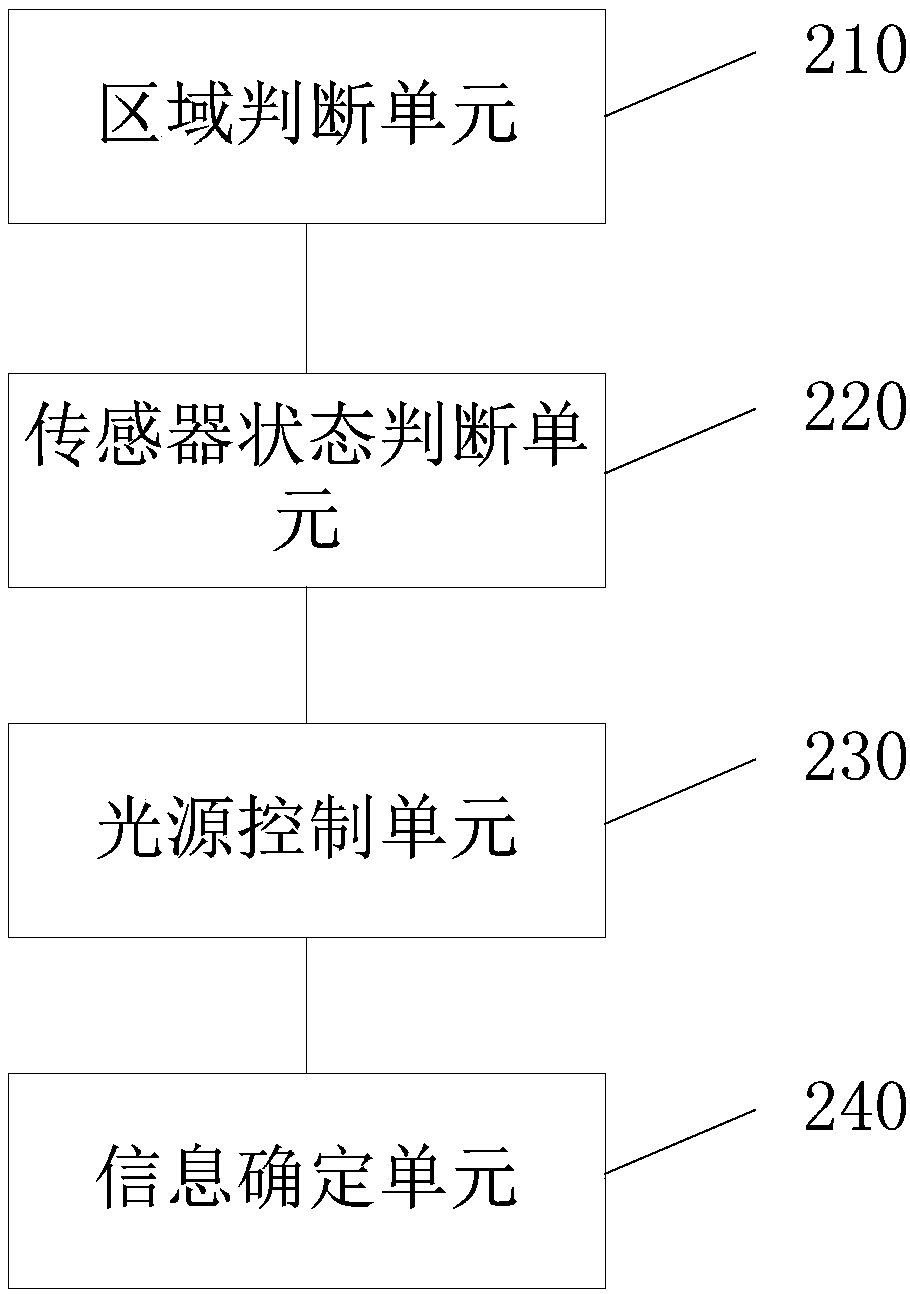

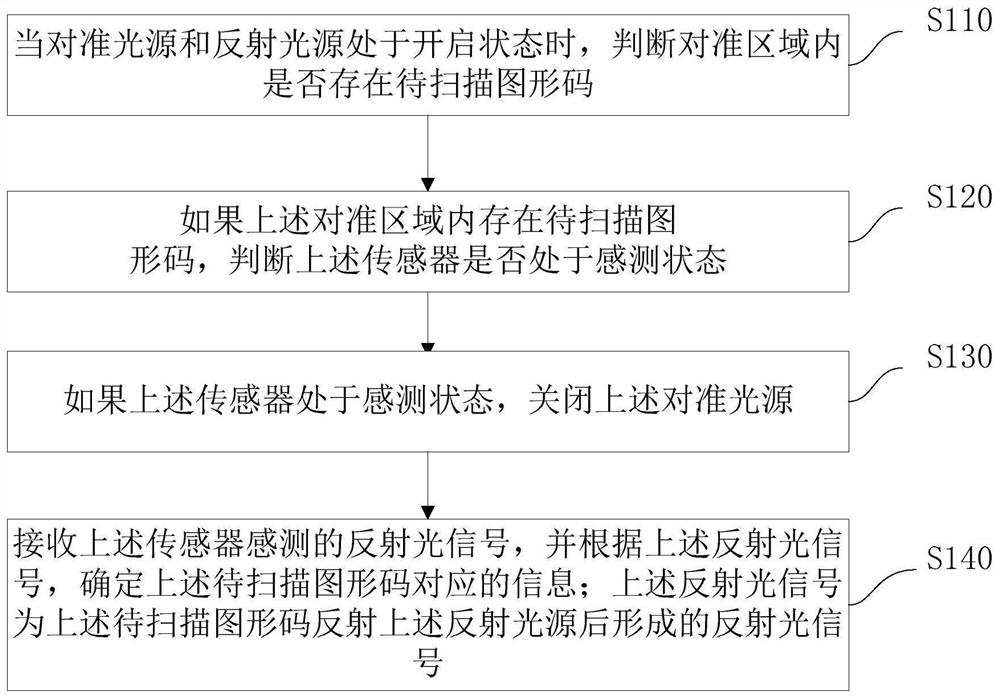

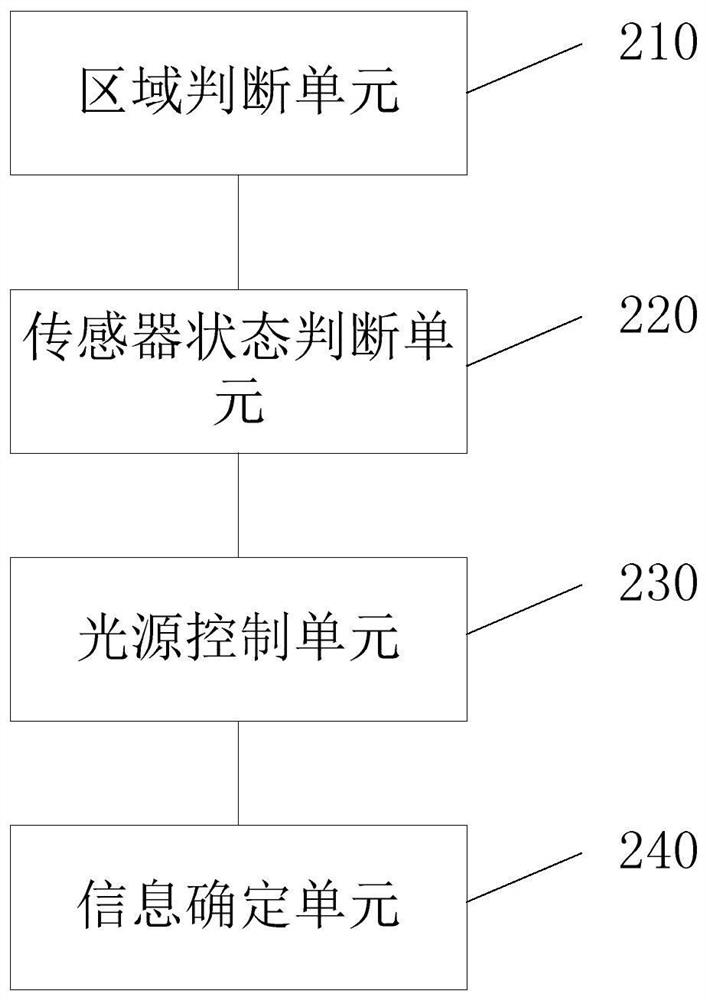

Graphic code scanning method and device and scanning gun

ActiveCN108920987AReduce optical signal errorImprove scan accuracySensing by electromagnetic radiationGraphicsLight signal

Embodiments of the present invention provide a graphic code scanning method and device, and a scanning gun. The method is applied to a processor in the scanning gun. The scanning gun further includesa sensor, an alignment light source, and a reflective light source. The method includes: determining whether there is a graphic code to be scanned in an alignment area when the alignment light sourceand the reflective light source are in an on state; determining whether the sensor is in a sensing state if there is the graphic code to be scanned in the alignment area; turning off the alignment light source if the sensor is in the sensing state; and receiving a reflective light signal sensed by the sensor, and determining information corresponding to the graphic code to be scanned according tothe reflective light signal. According to the technical scheme, an optical signal error of the reflected light source reflected by the graphic code received by the sensor is reduced, and the scanningaccuracy of the scanning gun is improved.

Owner:BEIJING D9ING INST OF INFORMATION ENG CO LTD +1

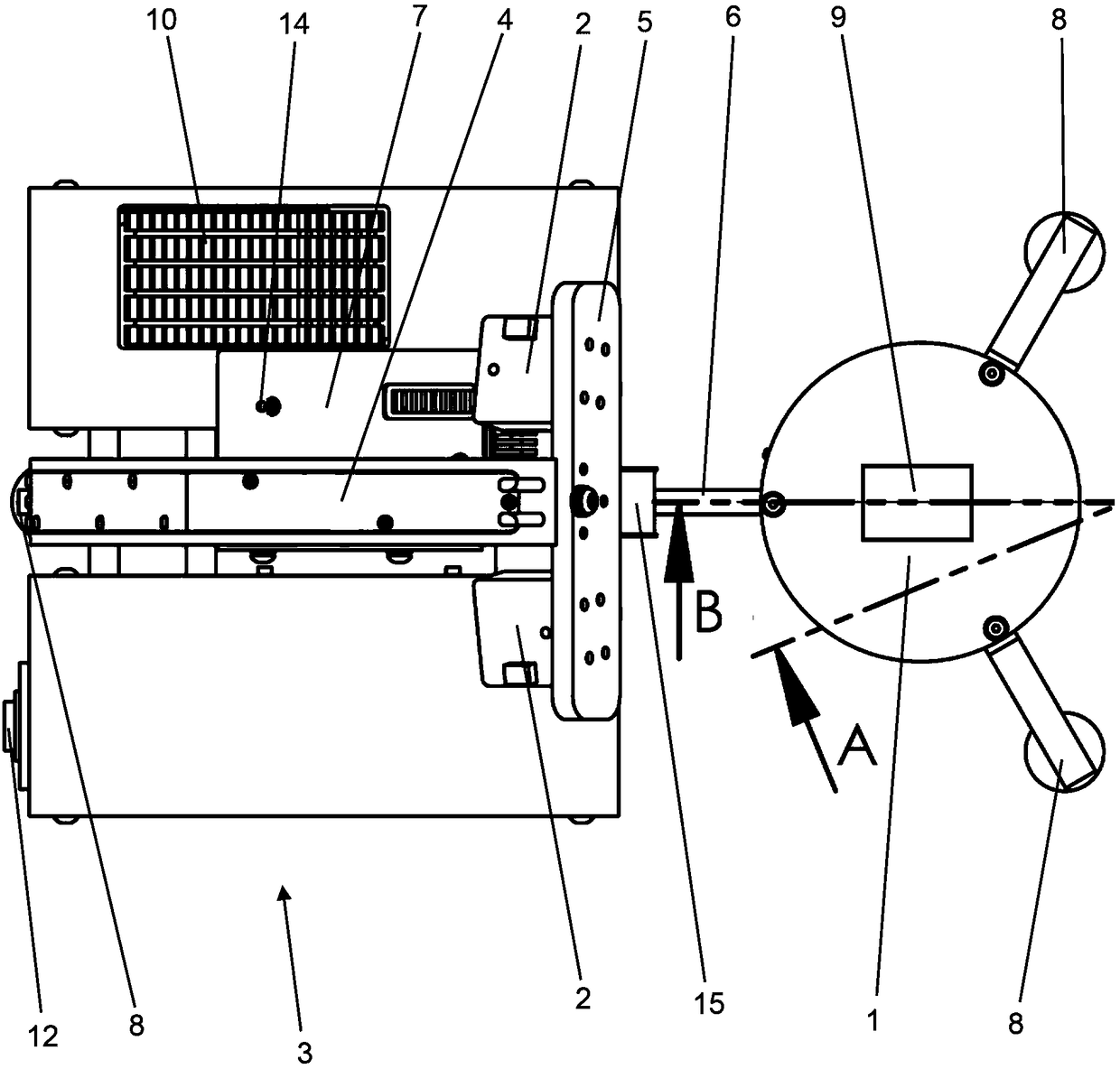

3D SCANNER WITH accelerometer

InactiveCN108507461ALow costReduce complexityImage analysisUsing optical meansAccelerometerComputer science

A 3D scanner with an accelerometer. The invention relates to a 3D scanner comprising at least one scanning module (2, 7) for acquiring three-dimensional (3D) coordinates of a surface of an object (9)and a positioning device (1) on which the object (9) is placeable or fixable, whereby the positioning device (1) is movable relative to the at least one scanning module (2, 7), and the 3D scanner further comprising at least one accelerometer, which is configured to measure a change of the position of the positioning device (1) relative to the scanning module (2, 7), and a first processing unit which is connected to the at least one scanning module (2, 7) and to the positioning device (1) for receiving data. The invention also relates to a method for scanning a surface of an object (9) to acquire three-dimensional (3D) coordinates of the surface.

Owner:库尔塞尔公司

A Method to Reduce False Positives in Vulnerability Scanning

ActiveCN110753047BReduce false alarm rateReduce follow-up workloadPlatform integrity maintainanceSecuring communicationData setEngineering

The invention relates to a method for reducing false alarms in vulnerability scanning. By scanning the system terminal, false alarm information and corresponding data are obtained, submitted to a shared server for manual review and identification, technical parameter adjustments, and synchronous correction schemes are provided. Finally, the terminal is based on Amendments are processed or repaired. The present invention can uniformly mark some types of vulnerabilities with a high false positive rate, clarify false positive points, refine the collected false positive entries, and then perform content analysis and refinement in a unified manner. The content of the report is professionally analyzed, whether it is misjudged and the corresponding correction is made, and the database and the vulnerability database are corrected; the present invention uses centralized data processing and update optimization processing to solve false positives, which not only improves the detection efficiency, but also collects effective Misreporting relevant data reduces follow-up workload, improves the accuracy of vulnerability scanning, reduces false positive rate, and greatly reduces duplication of work.

Owner:HANGZHOU ANHENG INFORMATION TECH CO LTD

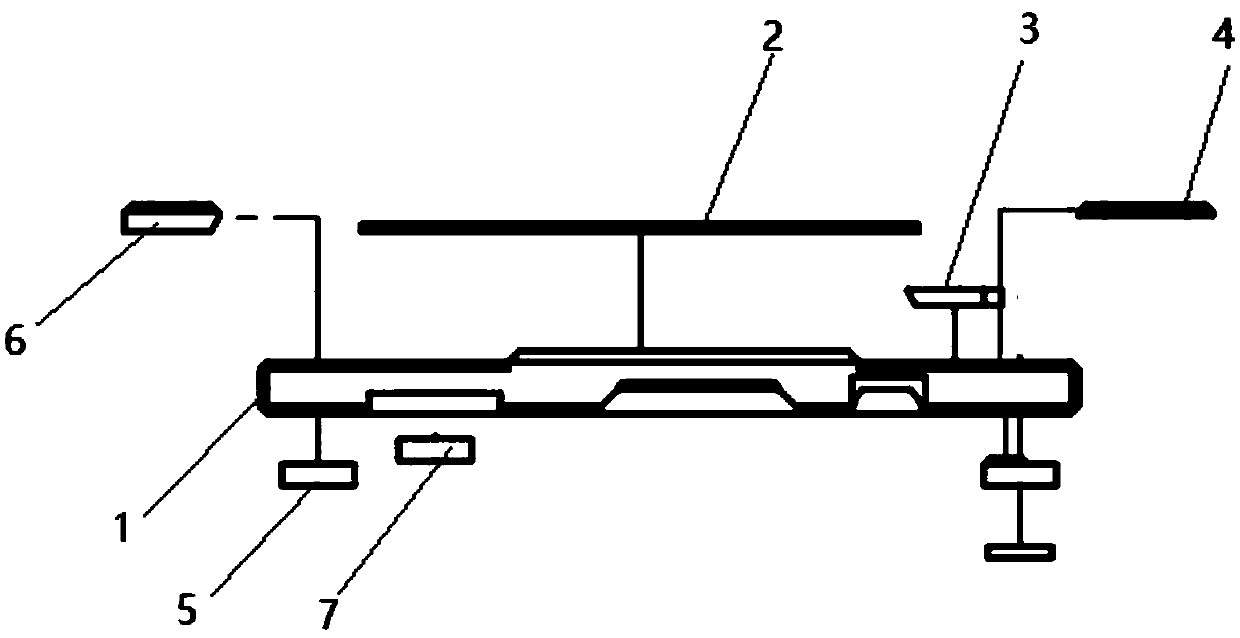

Portable desktop type white light three-dimensional scanner

PendingCN111464708AImprove work efficiencySimple structureMeasurement apparatus componentsPictoral communicationRotary stageEngineering

The invention provides a portable desktop type white light three-dimensional scanner, which belongs to the technical field of scanner equipment. The scanner comprises a scanning mechanism, a hydraulic telescopic rod and a base, the scanning mechanism is arranged above the base; the lower part of the scanning mechanism is connected with the base through a hydraulic telescopic rod; the scanning mechanism comprises three groups of scanners; a hydraulic mechanism is arranged in the base; the hydraulic mechanism is connected with the hydraulic telescopic rod; a storage table is arranged in the middle of the base; a rotating table is arranged in the middle of the storage table; the scanner is simple in structure, small in size, convenient to carry, easy and convenient to operate and high in automation degree, the three sets of the scanners are arranged to work at the same time to scan an object, the scanning precision is high, the scanning speed is high, and the working efficiency of three-dimensional scanning of the object is effectively improved.

Owner:上海玺太三维科技有限公司

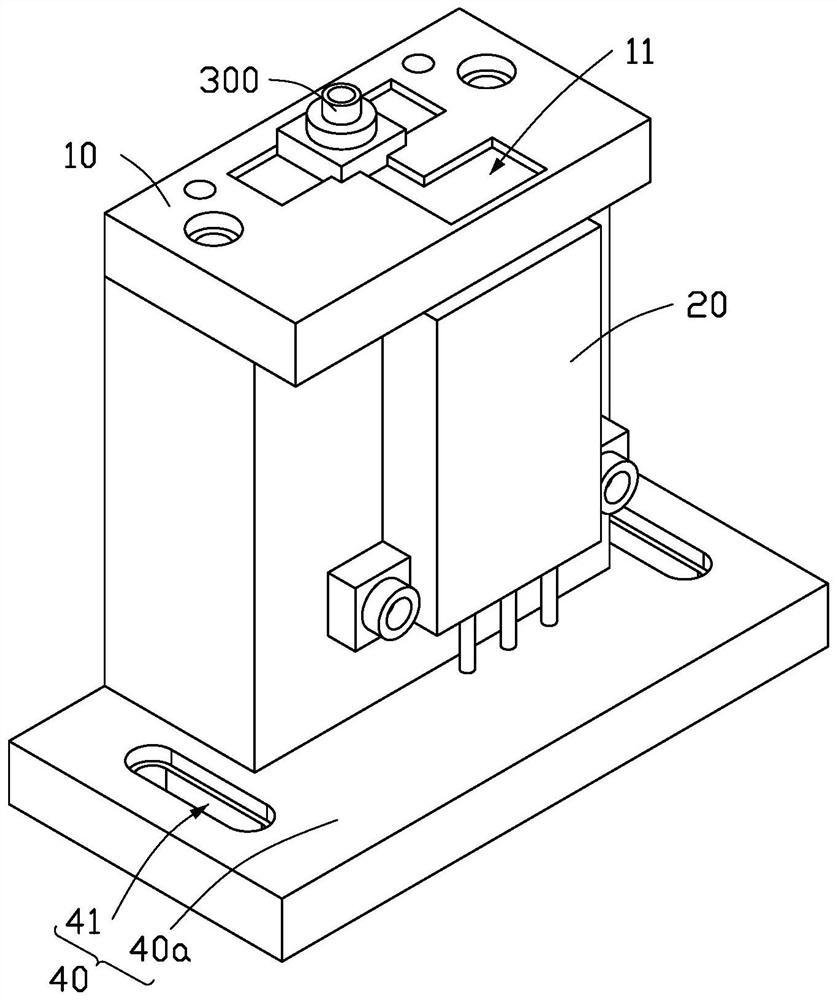

Scanning device

PendingCN114239617AAuto scanImprove scan accuracyMetal working apparatusSensing by electromagnetic radiationScannerAccuracy improvement

A scanning device comprises a scanner, a fixing seat, a sensor and a processor, the fixing seat is provided with a positioning groove, and the positioning groove is used for fixing a workpiece; the sensor is used for sensing whether workpieces exist on the fixed seat; the processor is in communication connection with the scanner and the sensor and is used for receiving signals of the sensor and sending instructions to the scanner; if the sensor senses that the workpiece is carried on the fixed seat, the processor controls the scanner to scan the identification code on the workpiece; and if the sensor senses that the fixed seat is vacant, the processor controls the scanner to stop scanning. According to the scanning device, after the height and the angle of the scanner are adjusted through the adjusting mechanism, the workpiece is placed on the fixing base, the sensor senses the workpiece and enables the processor to control the scanner to scan the identification code on the workpiece, after the workpiece is taken away, the processor controls the scanner to stop scanning, and the purposes of automatic scanning and scanning accuracy improvement are achieved.

Owner:TRIPLE WIN TECHSHENZHEN CO LTD

A three-dimensional scanning device and its control method

ActiveCN108775873BImprove scan accuracySimple designUsing optical meansRotational axisElectric machine

Owner:ZHEJIANG SHUREN UNIV

Automated fast batch scanning code assembly line for small express mail and its processing method

ActiveCN112093442BCompact structureEasy to useImage analysisGeometric image transformationControl systemControl engineering

The invention discloses an automated fast batch code scanning assembly line for small express mail and a processing method thereof, including an automatic transport vehicle, a pallet feeder, a conveyor line, a batch code scanner and a control system. The ends are set respectively, the batch code scanning machine includes a camera installation frame correspondingly arranged above the output end of the conveying line and a supporting connection device arranged on the side of the conveying line to support and connect the camera installation frame, and the automatic transport vehicle is used for The pallet feeder feeds in or outputs the loading and transporting of the coded pallets. The automatic transport vehicle is equipped with a lifting support platform for erecting the coded pallets. The control system controls the working operation of the whole machine and the code scanning identification control. The assembly line has high level of automation, high work efficiency, compact mechanical structure and stable work.

Owner:SF TECH +1

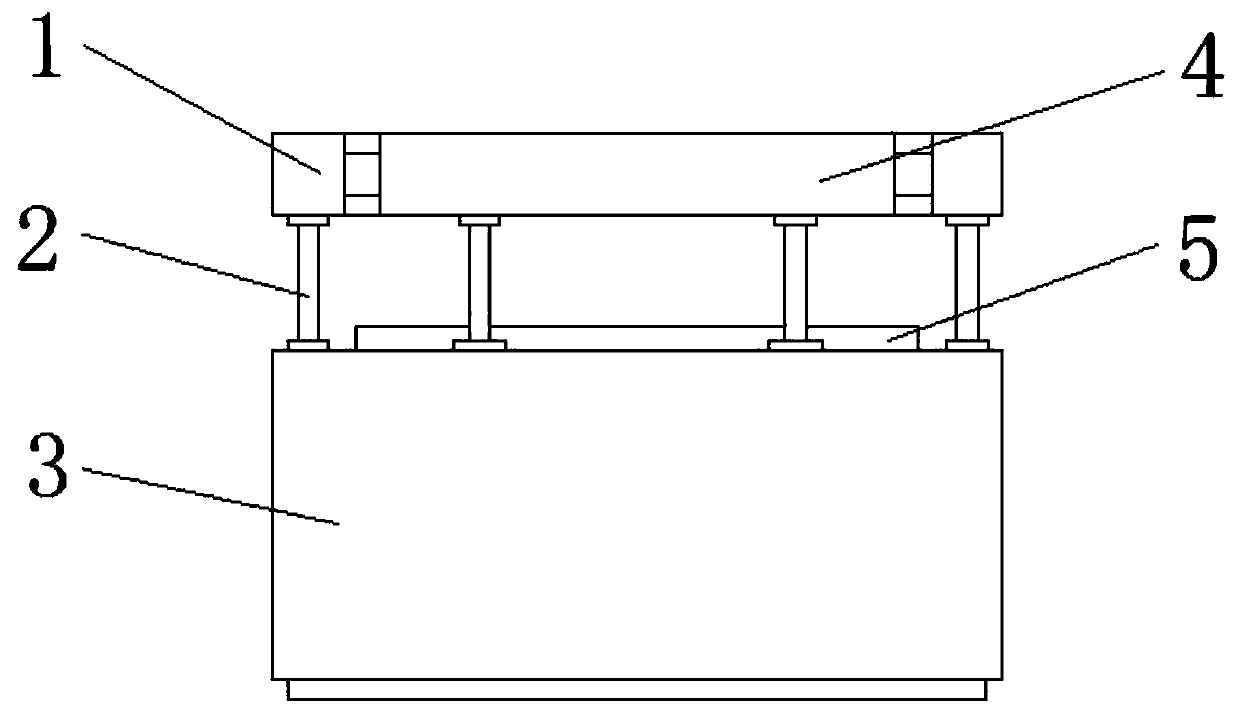

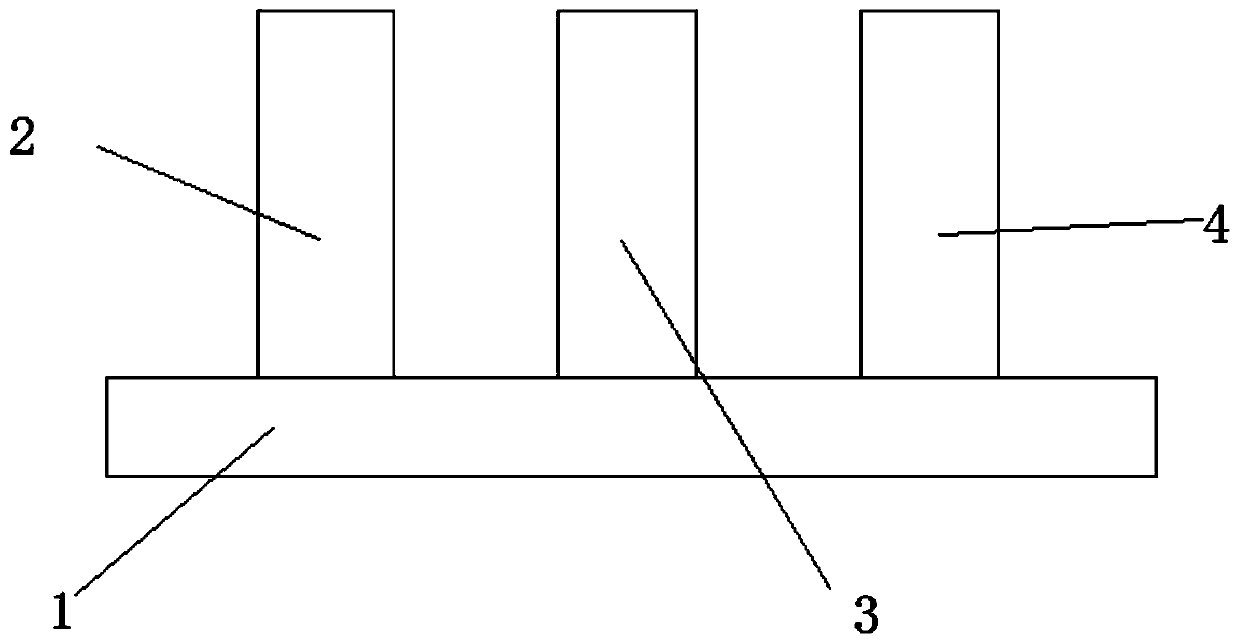

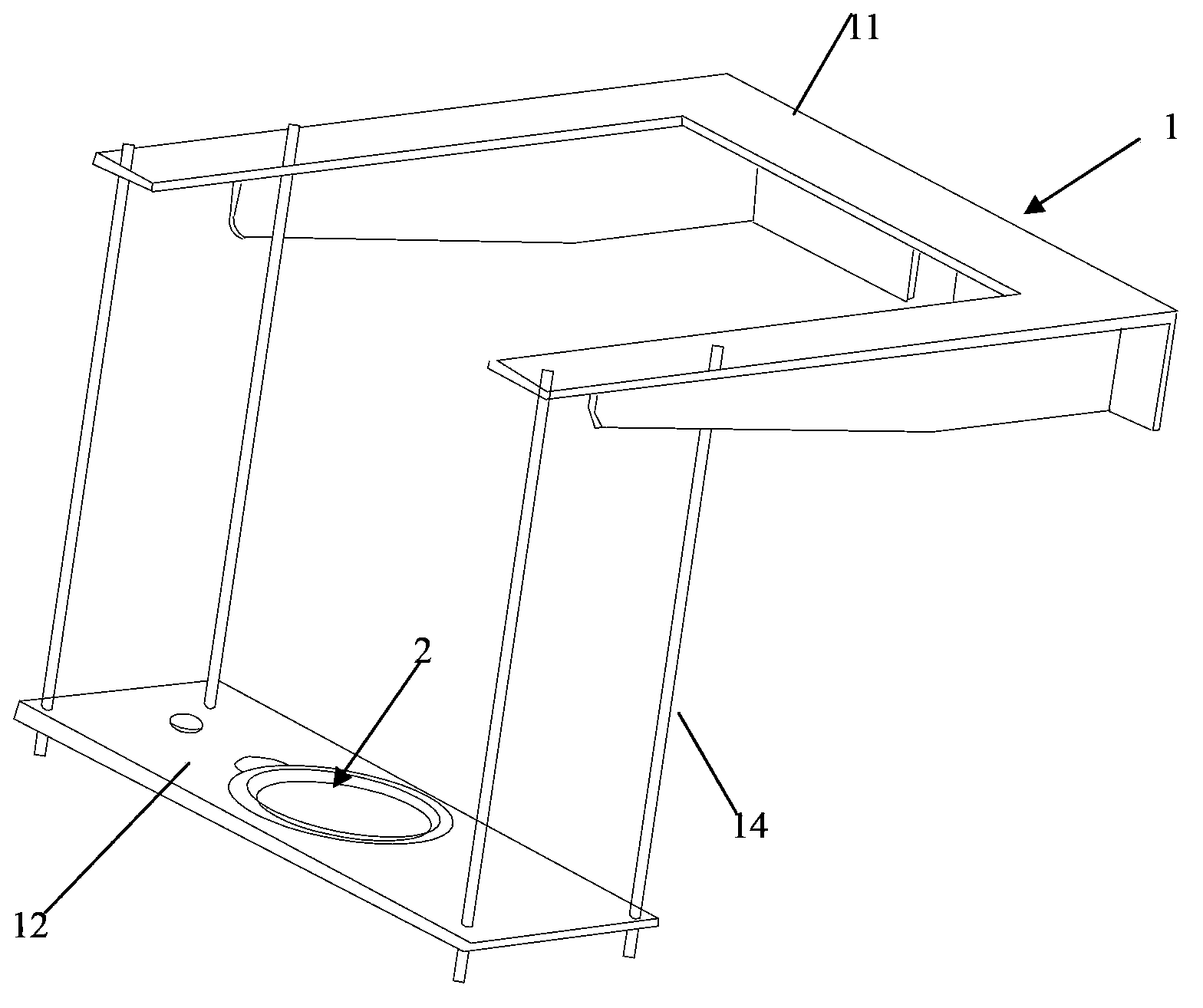

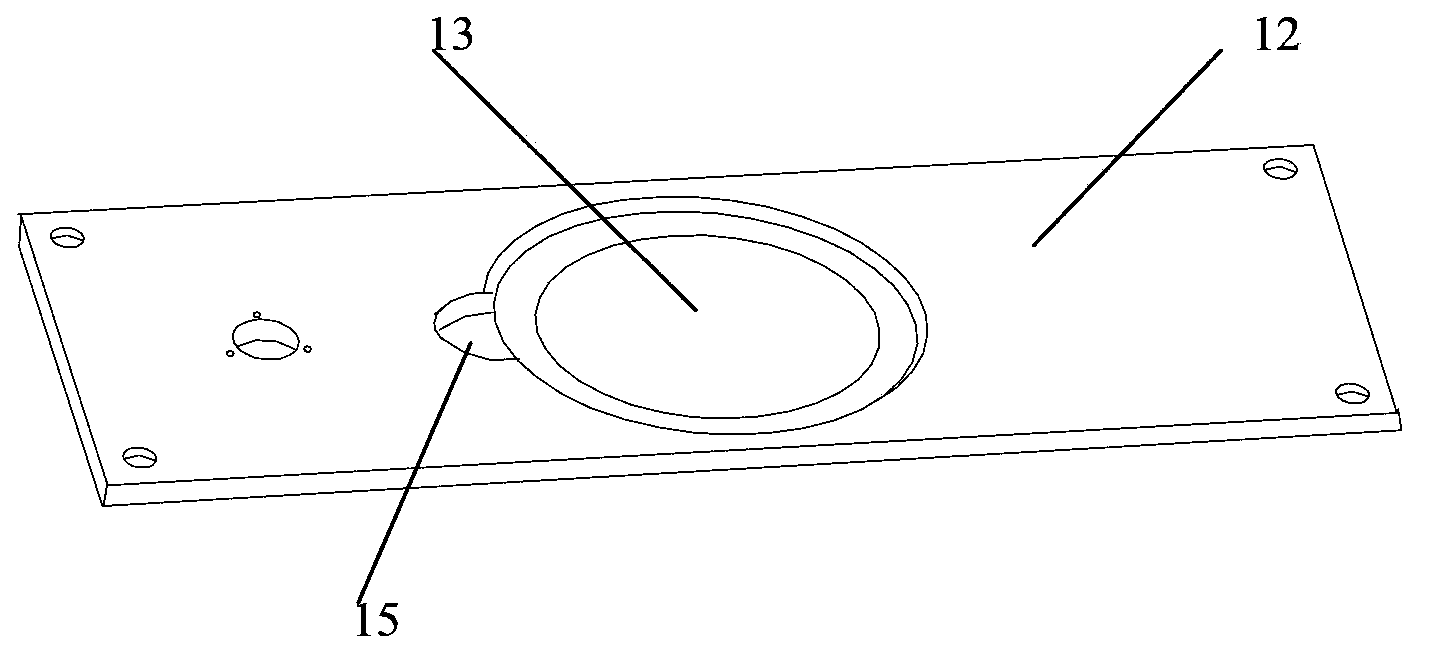

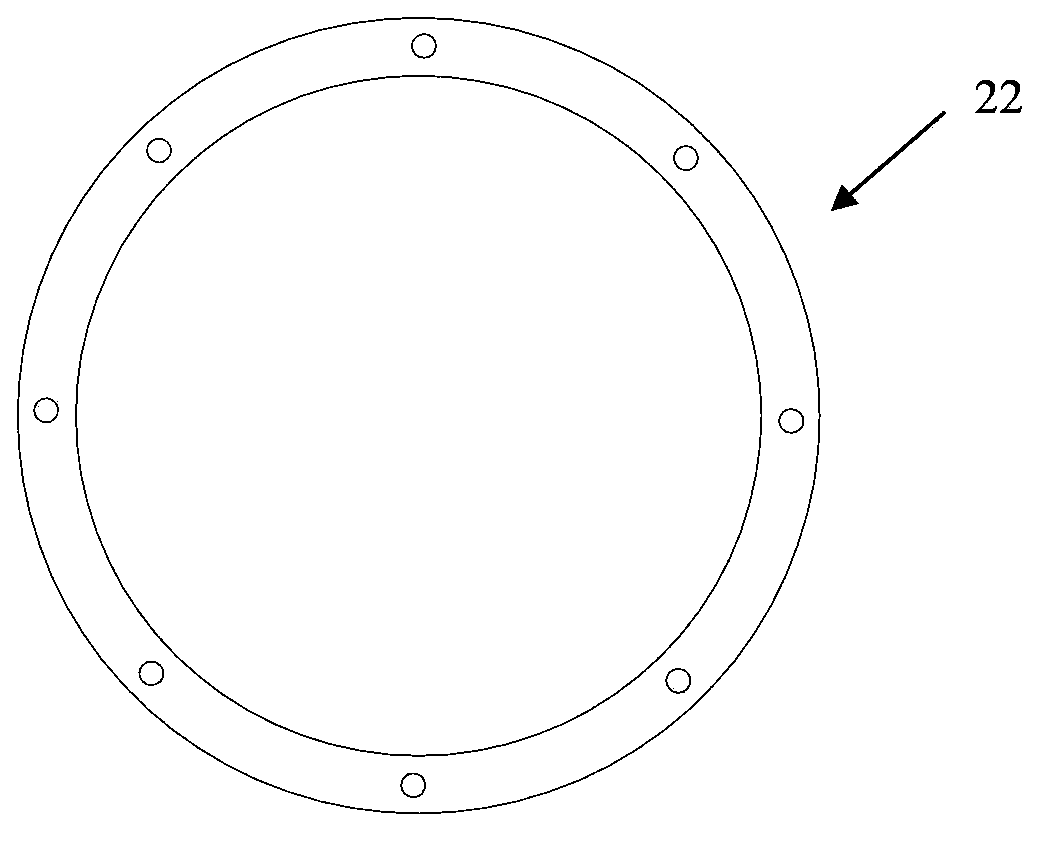

Sample sampling device of NDC measuring system

ActiveCN103776655AStable structureImprove scan accuracyWithdrawing sample devicesEngineeringPole piece

The invention discloses a sample sampling device of an NDC measuring system, which includes a sampling rack and a sample fixture, wherein the sampling rack includes a U-shaped main frame fixedly connected with an NDC scanner, and a sample support plate horizontally and fixedly connected under the opening end of the U-shaped main frame; a through hole matched with the sample fixture is arranged at the center of the sample support plate; an inner flange is arranged at the bottom of the through hole to support and position the sample fixture; the sample fixture includes a lower ring body and an upper ring body; the upper ring body and the lower ring body clamp a sample therebetween and are fixedly connected through uniformly distributed screws. According to the sample sampling device provided by the invention, a qualified pole piece is placed on the sampling rack, and the qualified pole piece can be simulated, then the produced pole piece can be compared with the qualified pole piece (sample), so that whether the produced pole piece is qualified or not can be directly verified, as a result, destructive measurement on pole pieces and waste of quailed products are avoided.

Owner:TIANJIN LISHEN BATTERY +1

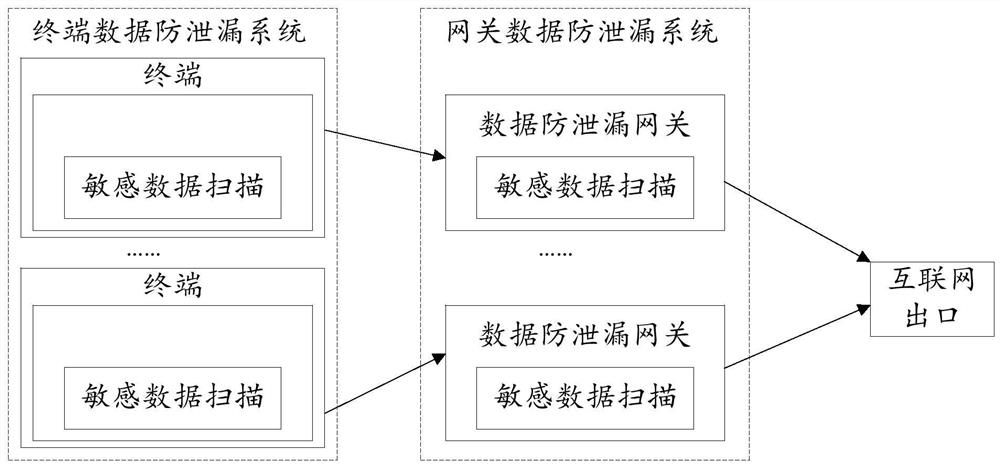

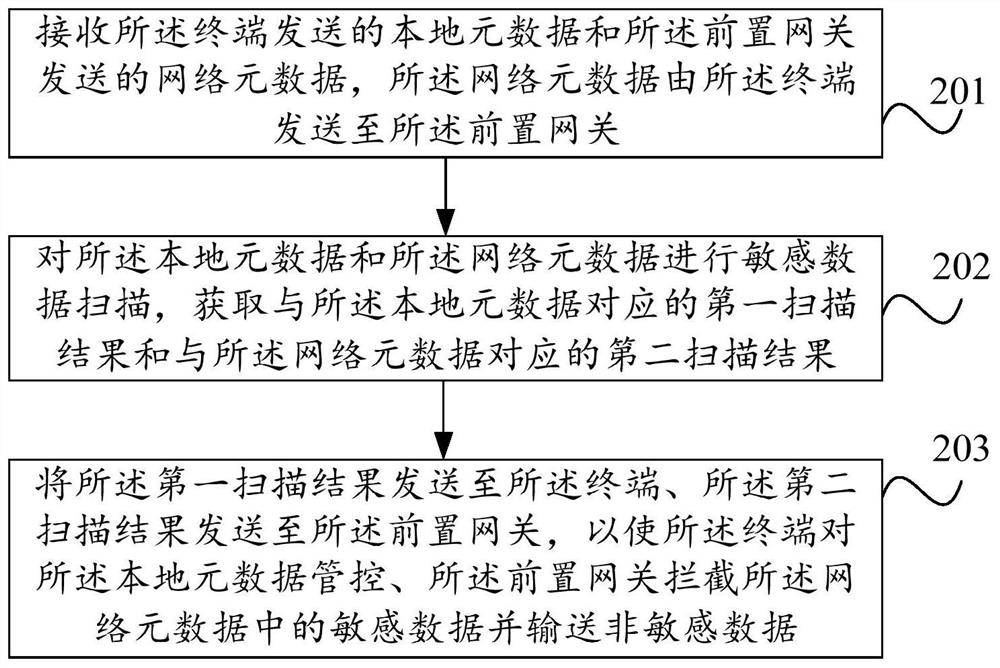

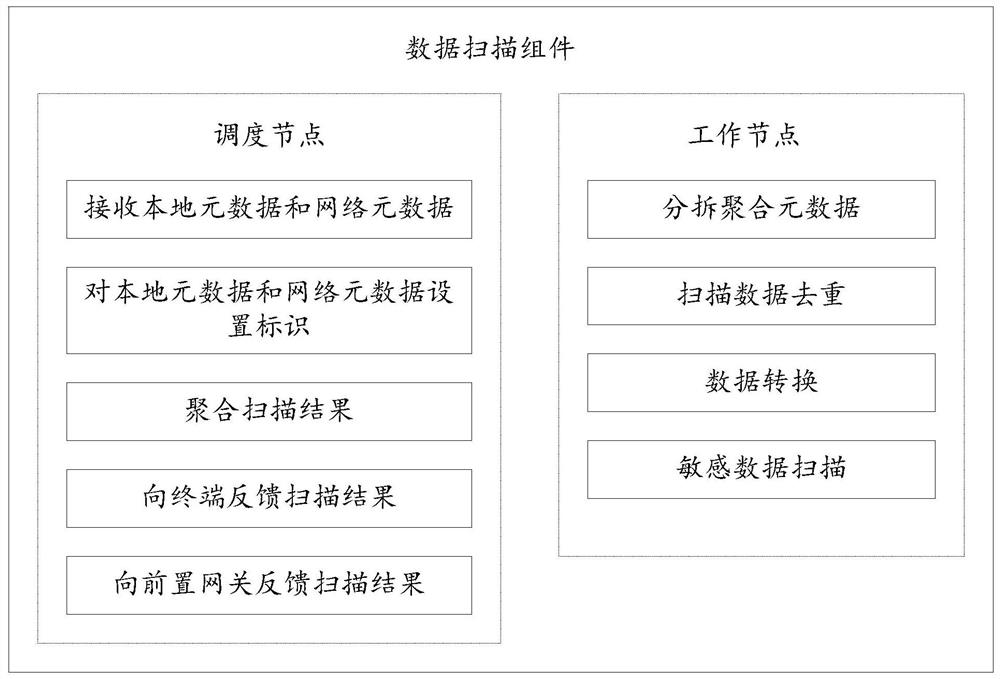

Data scanning method and device, data management and control method and device, electronic equipment and readable storage medium

The invention provides a data scanning method and device, a data management and control method and device, electronic equipment and a readable storage medium, the data scanning method is applied to adata scanning component, the data scanning component, a terminal and a front gateway are in communication connection with one another, and the method comprises the following steps: receiving local metadata sent by the terminal and network metadata sent by the front gateway; conducting sensitive data scanning on the local metadata and the network metadata, and acquiring a first scanning result corresponding to the local metadata and a second scanning result corresponding to the network metadata; sending the first scanning result to the terminal, sending the second scanning result to the front gateway, so that the terminal controls the local metadata, and the front gateway intercepts the sensitive data in the network metadata and transmits the non-sensitive data. According to the invention,the chaos of the sensitive data is reduced, the low-delay gateway sensitive data scanning capability is realized, the bandwidth occupation of invalid traffic is reduced, and the scanning accuracy andthe availability of the terminal are improved.

Owner:北京明朝万达科技股份有限公司

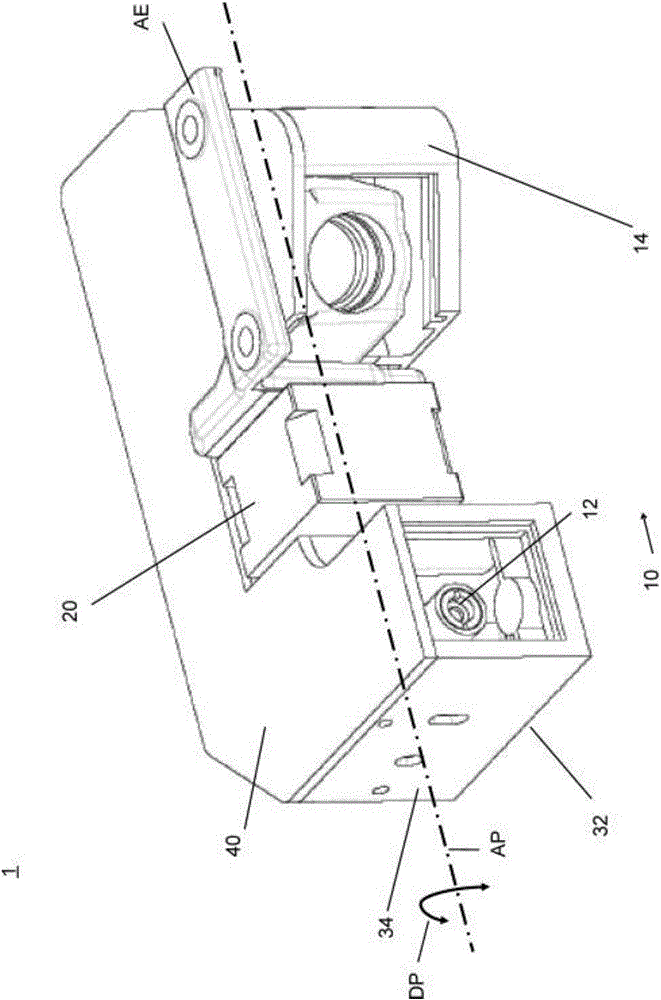

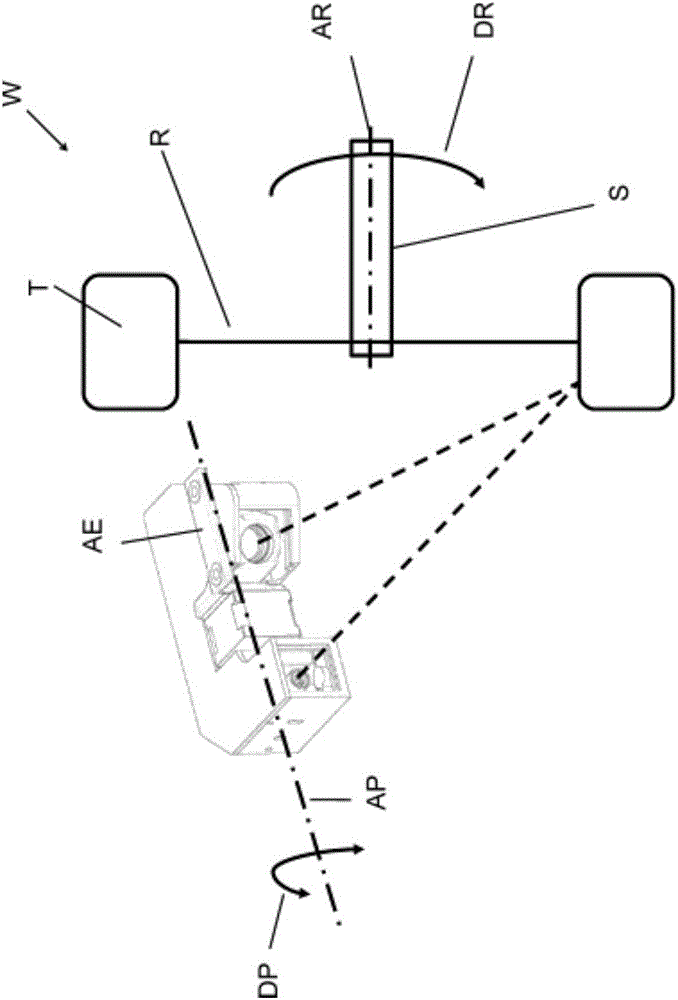

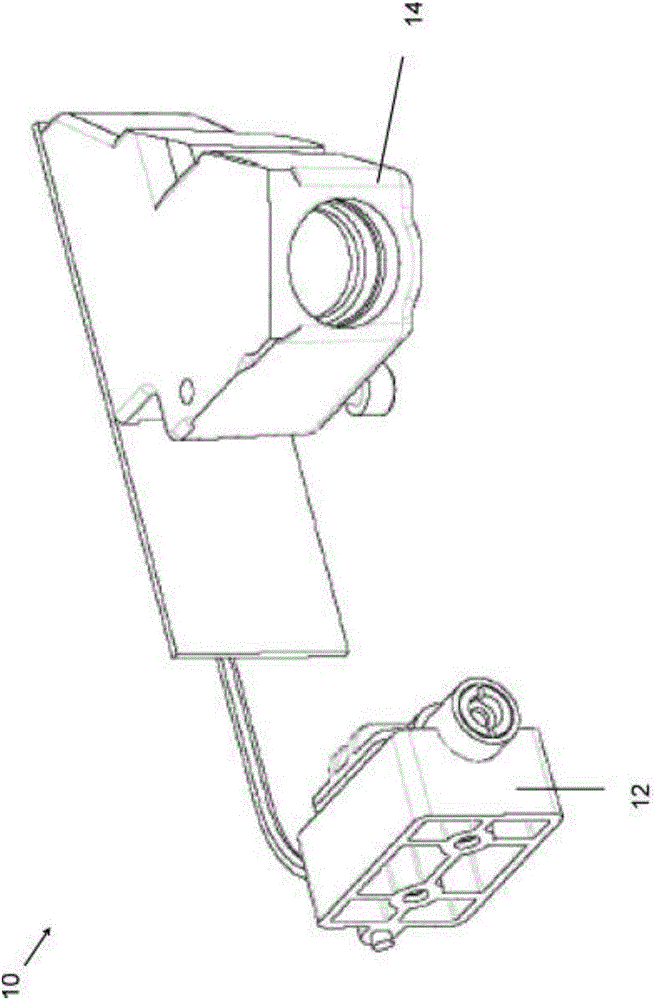

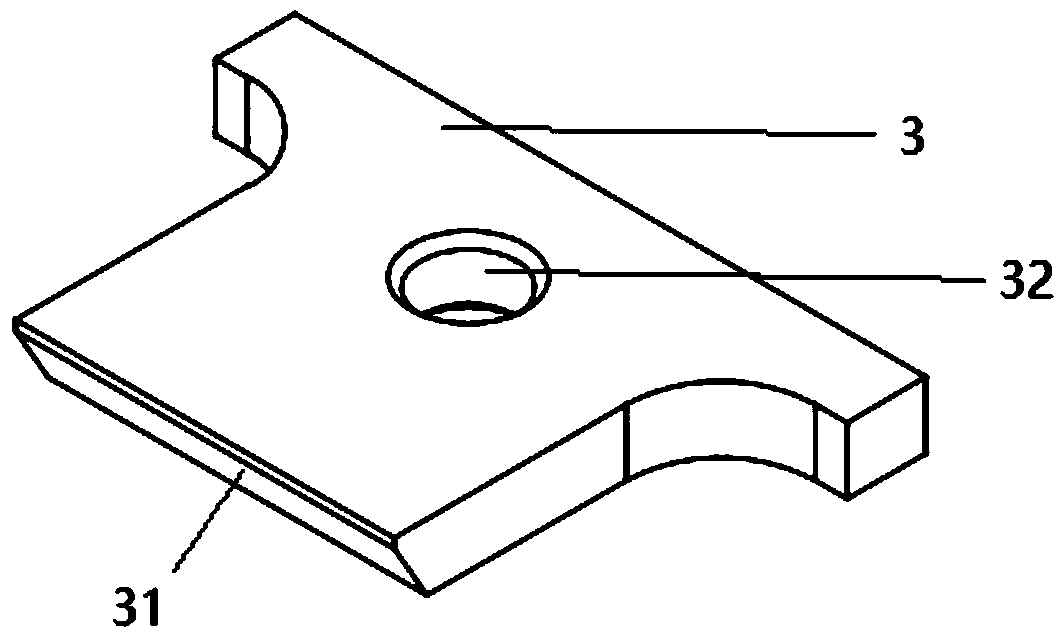

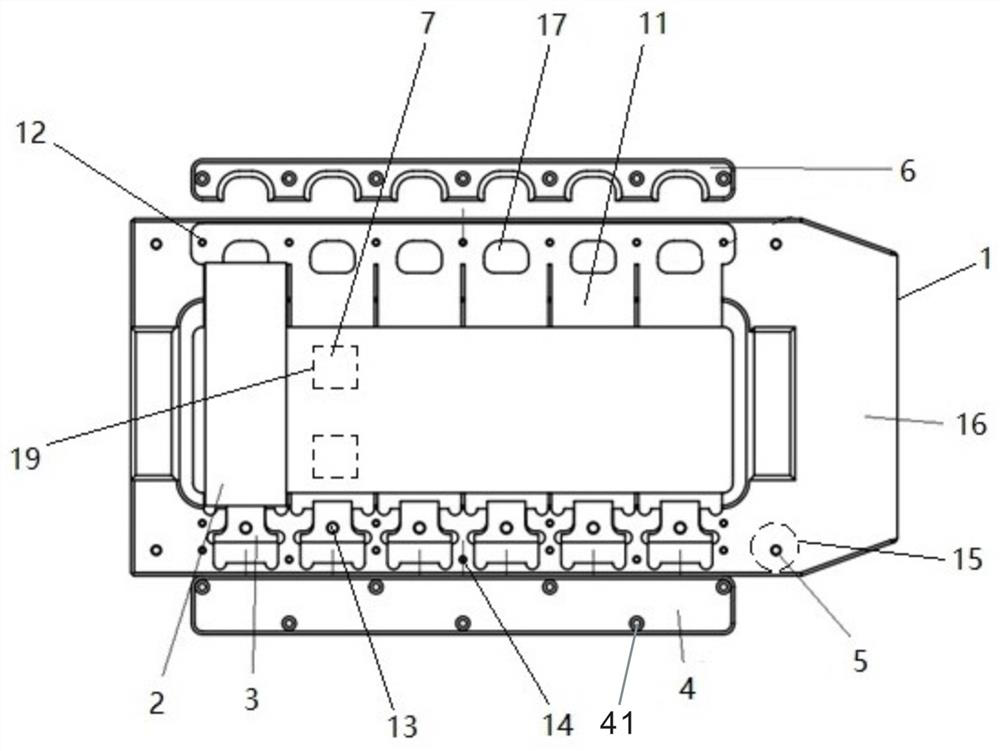

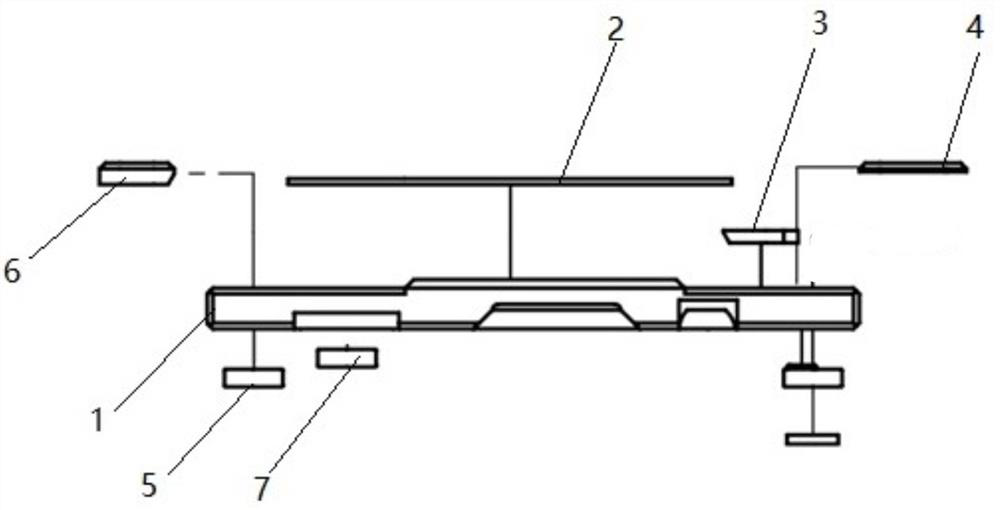

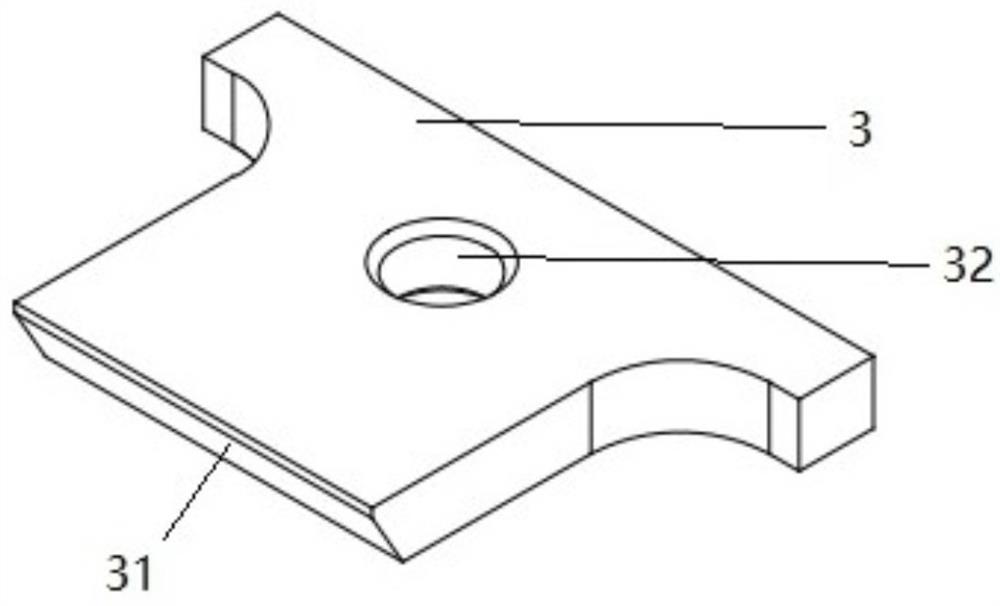

Wheel service machine with compact sensing device

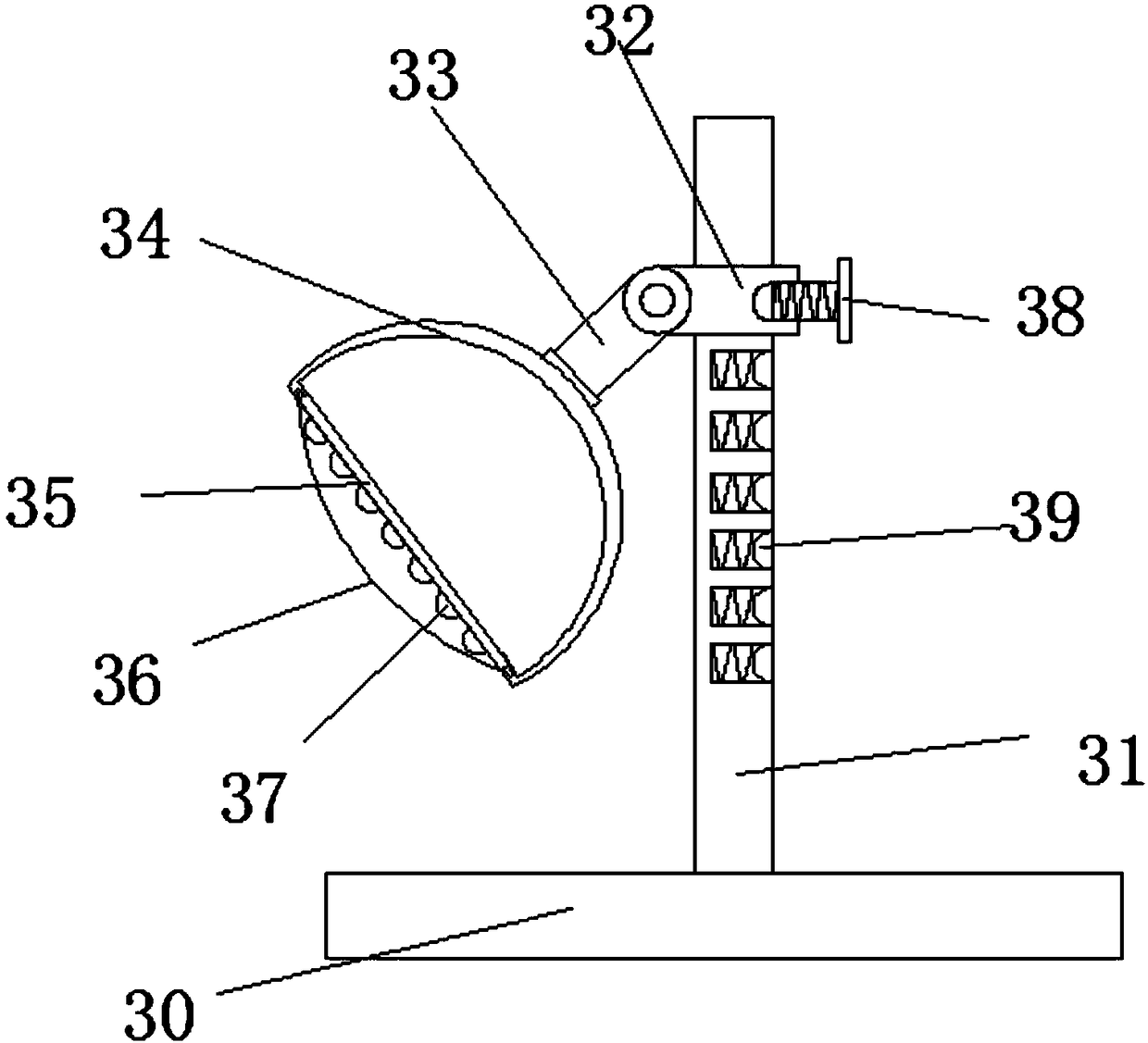

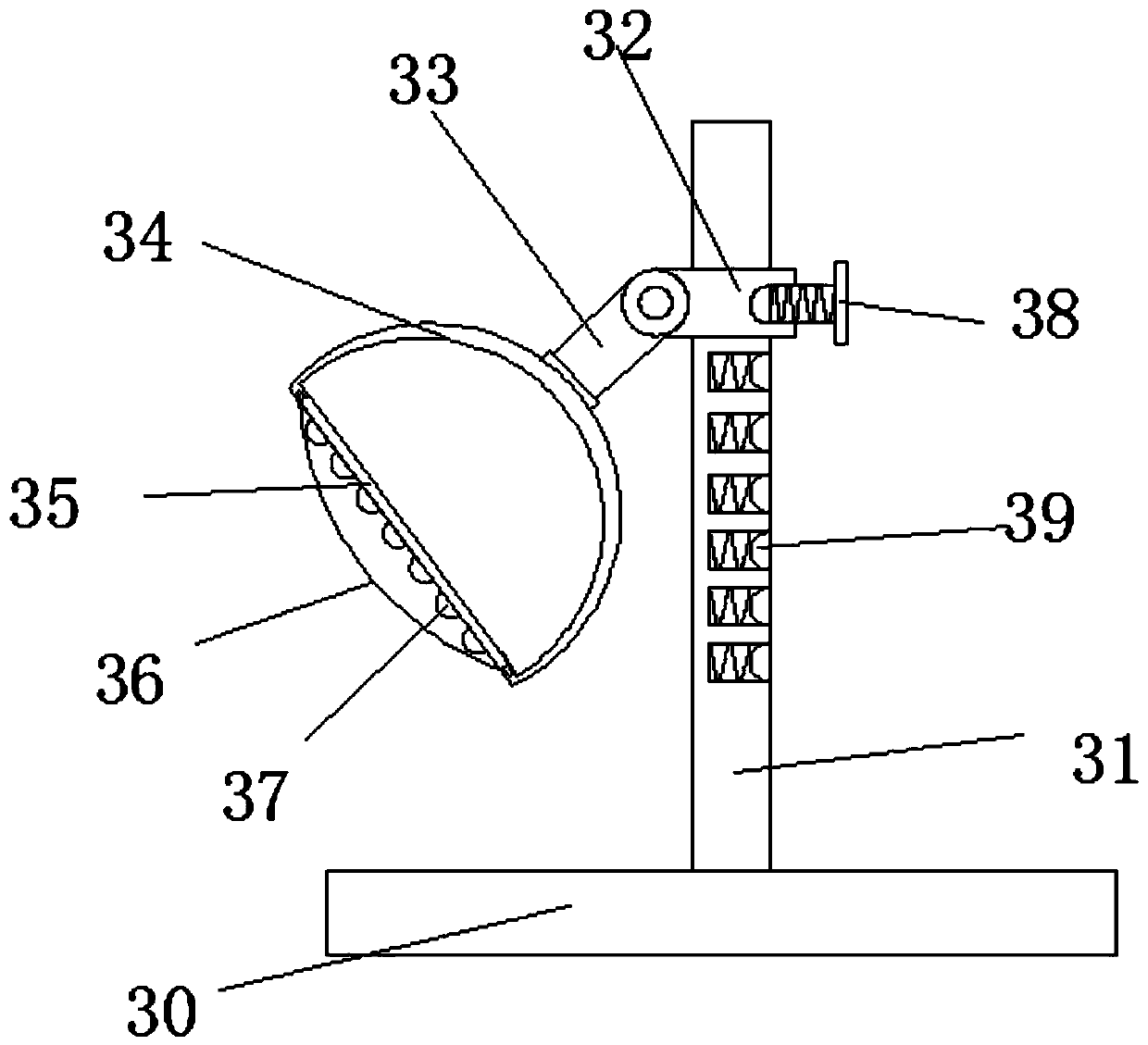

ActiveCN106370099ASimple and smaller constructionHigh resolutionStatic/dynamic balance measurementUsing optical meansEngineeringStepper motor

The invention relates to a wheel service machine with a compact sensing device. The present invention relates to a wheel service machine and a method for servicing a wheel. The wheel service machine (50), like a tyre changer or a wheel balancer, for servicing a wheel (W), like a vehicle wheel, comprises a rotary mounting member including a shaft (S) to which the wheel (W) is mounted, a framework for carrying at least the rotary mounting member and a sensing device (1) mounted to the framework, for determining geometrical dimensions of the wheel (W), or parts of the wheel (W), the sensing device (1) comprises a carrier element (30) and a first sensing unit (10) for sensing the wheel (W) and computing means for determining the geometrical dimensions of the wheel (W) based on the data received from the sensing device (1), the first sensing unit (10) being mounted on the carrier element (30), the wheel service machine further comprises a drive means (20) for enabling a pivotal movement of the sensing device (1), wherein the drive means (20) is a micro stepper motor.

Owner:SNAP ON EQUIP

Graphical code scanning method, device and scanning gun

ActiveCN108920987BReduce optical signal errorImprove scan accuracySensing by electromagnetic radiationGraphicsEngineering

Embodiments of the present invention provide a graphic code scanning method, device, and scanning gun, wherein the method is applied to a processor in the scanning gun, and the scanning gun also includes a sensor, an alignment light source, and a reflection light source. The method includes : When the alignment light source and reflection light source are turned on, judge whether there is a pattern code to be scanned in the alignment area; if there is a pattern code to be scanned in the alignment area, judge whether the sensor is in the sensing state; if the sensor is in the sensing state , turn off the alignment light source; receive the reflected light signal sensed by the sensor, and determine the information corresponding to the pattern code to be scanned according to the reflected light signal. The technical solution of the embodiment of the present invention can reduce the light signal error of the reflected light source reflected by the graphic code received by the sensor, and improve the scanning accuracy of the scanning gun.

Owner:BEIJING D9ING INST OF INFORMATION ENG CO LTD +1

Full-automatic multi-faceted code scanning, weighing and volume measurement system for express mail and its processing method

ActiveCN112179272BReduce investmentSave operating timeUsing optical meansStacking articlesComputer hardwareFace scanning

The present invention relates to the field of full-automatic code scanning measurement system for express mail, and specifically discloses a full-automatic multi-faceted code scanning, weighing, and volume measurement system for express mail and a processing method thereof, including an automatic transport forklift, a multi-axis manipulator, a bottom-side code-scanning camera, and a side-side code-scanning system. Camera, top scanning code scanning volume measurement camera, scanning code weighing conveyor line and control system, multi-axis manipulators are respectively set at both ends of the code scanning and weighing conveyor line, automatic transport forklifts are used The code camera is set under the working range of the multi-axis manipulator, the side code scanning camera is correspondingly set on the side of the working end range of the multi-axis manipulator, and the top scanning code measuring volume camera is correspondingly set at the side of the code scanning weighing conveyor line Above, the control system controls the operation of the whole machine, and a gravity sensor is installed on the code scanning and weighing conveyor line. This system changes the traditional conveying method, and realizes automatic express processing such as multi-faceted code scanning, weighing, and volume measurement, and has high work efficiency, compact mechanical structure, and stable work.

Owner:SF TECH +1

A laser scanning system and method based on a mobile intelligent terminal

ActiveCN105550621BImprove scan accuracyScan code error rate is zeroSensing by electromagnetic radiationControl systemComputer module

The invention discloses a laser barcode scanning system and method based on a mobile intelligent terminal, and belongs to the technical field of laser barcode scanning. The system comprises a barcode scanning sensing module, a level conversion module, a signal processing module, a serial port driving module, a JNI (Java Native Interface) module, a scanning service module, an application system module and a display module. The method comprises the following steps: 1) starting serial port equipment, and controlling a scanning mode; 2) scanning and processing data; 3) receiving the data, and carrying out data conversion; 4) registering a callback interface, and calling the JNI module to provide a service interface for an upper-layer application; and 5) controlling the system to select a UI (User Interface) display way, and displaying a result. The laser barcode scanning system and method are completely realized on the basis of the mobile intelligent terminal, scanning accuracy is improved, scanning is not restricted by environment, barcode scanning speed is quickened, and the equipment is convenient in carrying, is small and portable and is especially suitable for occasions of mobile office.

Owner:JIANGSU ZHILIAN TIANDI TECHNOLOGY CO LTD

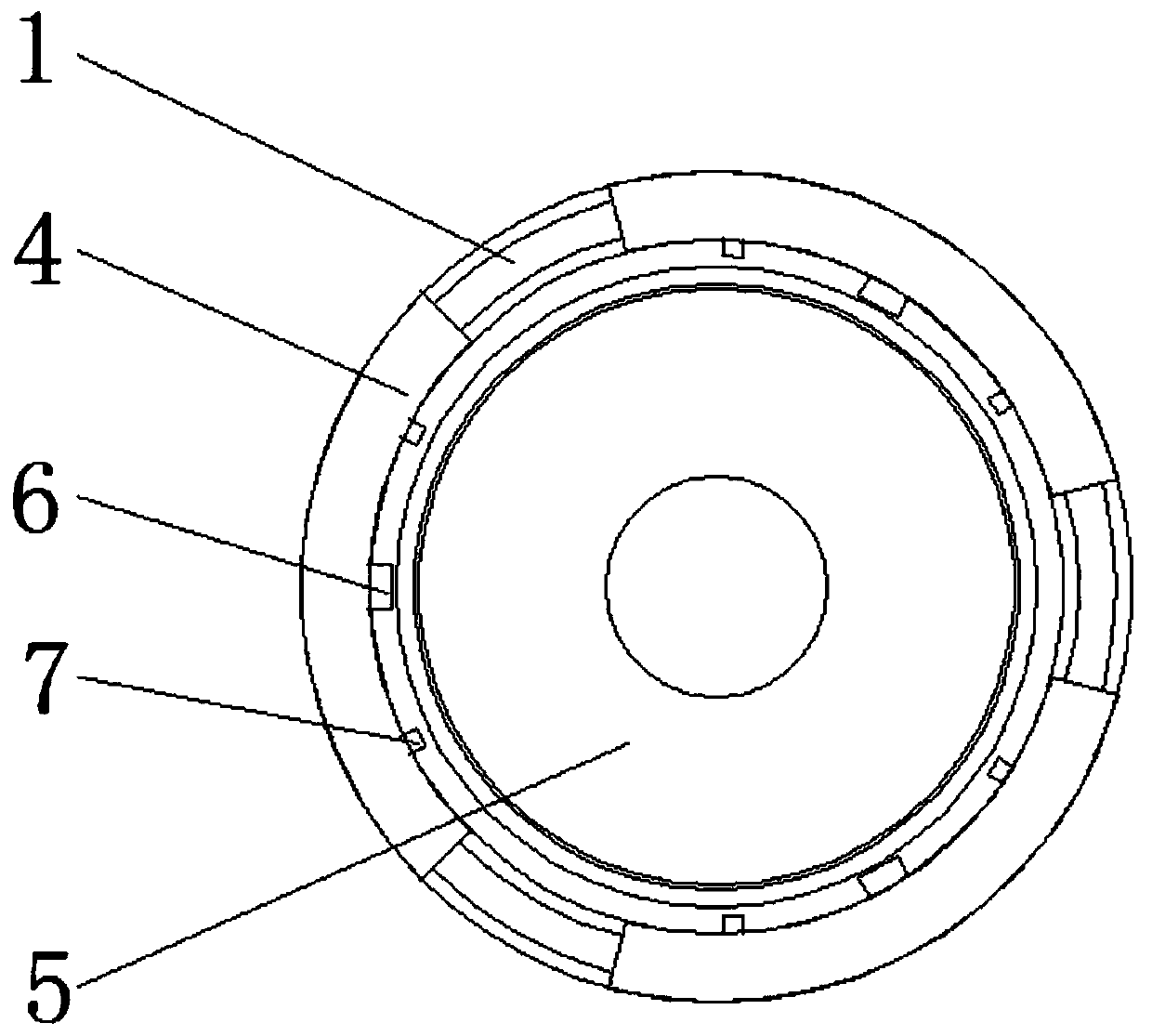

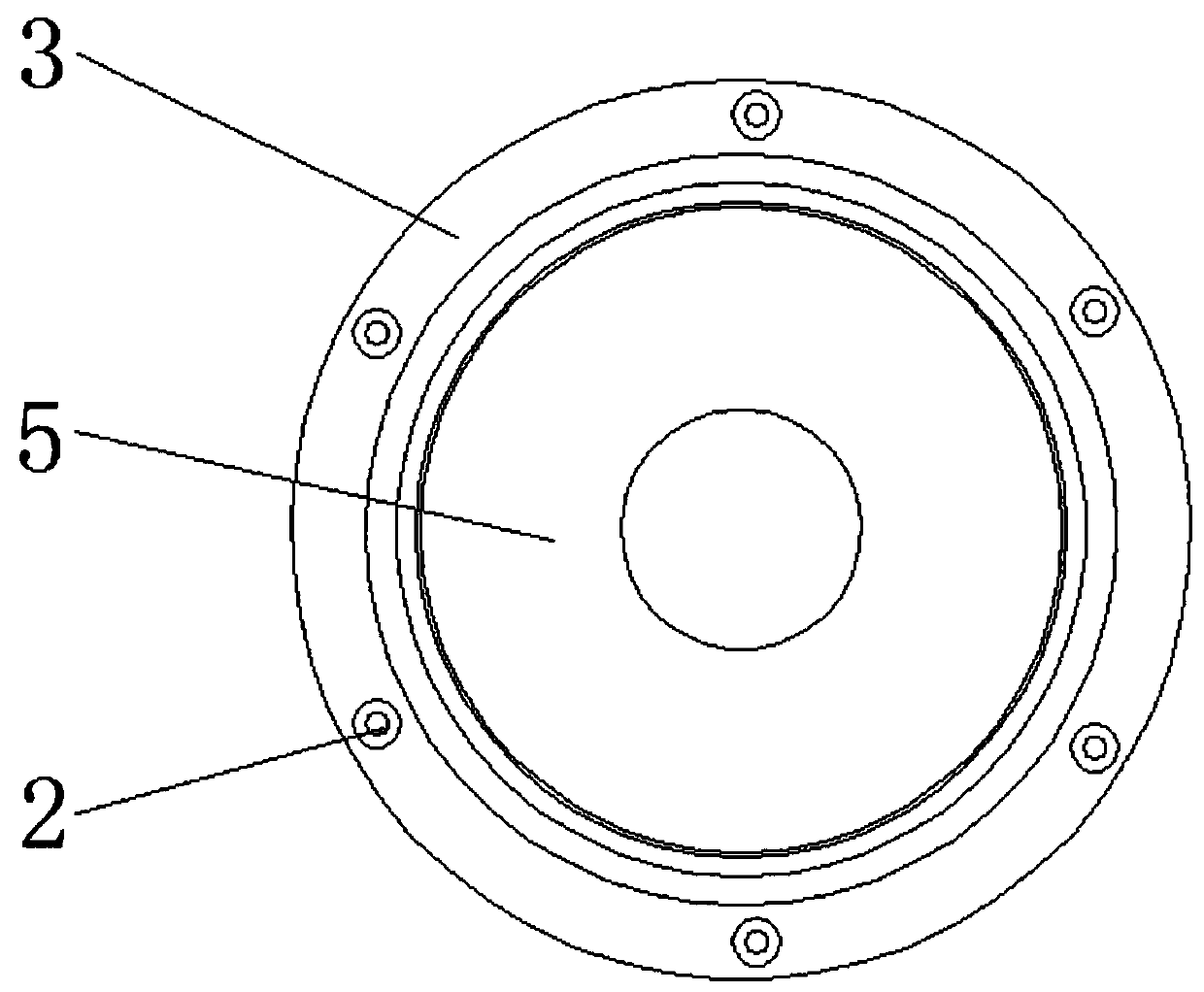

Slide glass disc of microscopic scanner

The invention discloses a slide glass disc of a microscopic scanner. The slide glass disc comprises a slide glass disc body, slide glass, slide glass jacking blocks, a jacking block pressing plate, a disc fixing magnet, a slide glass top plate and square magnets; the upper side of multiple slide glass stations in the front side of the slide glass disc body is provided with the slide glass top plate, the lower side of the same is provided with the slide glass jacking blocks and the jacking block pressing plate, and the two ends of the slide glass are clamped between a first inclined plane of the slide glass jacking blocks and a slide glass contact side of the slide glass top plate; and the back side of the slide glass disc body is provided with the square magnets corresponding to the slide glass stations, the slide glass is adsorbed onto the square magnet of a first magnet seat in the back side of the slide glass disc body, and the slide glass and slide glass disc body are stably installed. Disc fixing magnets are arranged in four corners of the back side of the slide glass disc body respectively, when the slide glass disc body is placed on an objective table, the slide glass disc body is absorbed with the objective table via the disc fixing magnets, and the slide glass is scanted by a microscope continuously via movement of the objective table; and the slide glass disc also has the advantages of high placing stability, low jittering, low work deviation, high scanning accuracy and easy replacement of the slide glass.

Owner:EAST CHINA NORMAL UNIV +2

A glass tray for a microscope scanner

The invention discloses a slide glass disc of a microscopic scanner. The slide glass disc comprises a slide glass disc body, slide glass, slide glass jacking blocks, a jacking block pressing plate, a disc fixing magnet, a slide glass top plate and square magnets; the upper side of multiple slide glass stations in the front side of the slide glass disc body is provided with the slide glass top plate, the lower side of the same is provided with the slide glass jacking blocks and the jacking block pressing plate, and the two ends of the slide glass are clamped between a first inclined plane of the slide glass jacking blocks and a slide glass contact side of the slide glass top plate; and the back side of the slide glass disc body is provided with the square magnets corresponding to the slide glass stations, the slide glass is adsorbed onto the square magnet of a first magnet seat in the back side of the slide glass disc body, and the slide glass and slide glass disc body are stably installed. Disc fixing magnets are arranged in four corners of the back side of the slide glass disc body respectively, when the slide glass disc body is placed on an objective table, the slide glass disc body is absorbed with the objective table via the disc fixing magnets, and the slide glass is scanted by a microscope continuously via movement of the objective table; and the slide glass disc also has the advantages of high placing stability, low jittering, low work deviation, high scanning accuracy and easy replacement of the slide glass.

Owner:EAST CHINA NORMAL UNIV +2

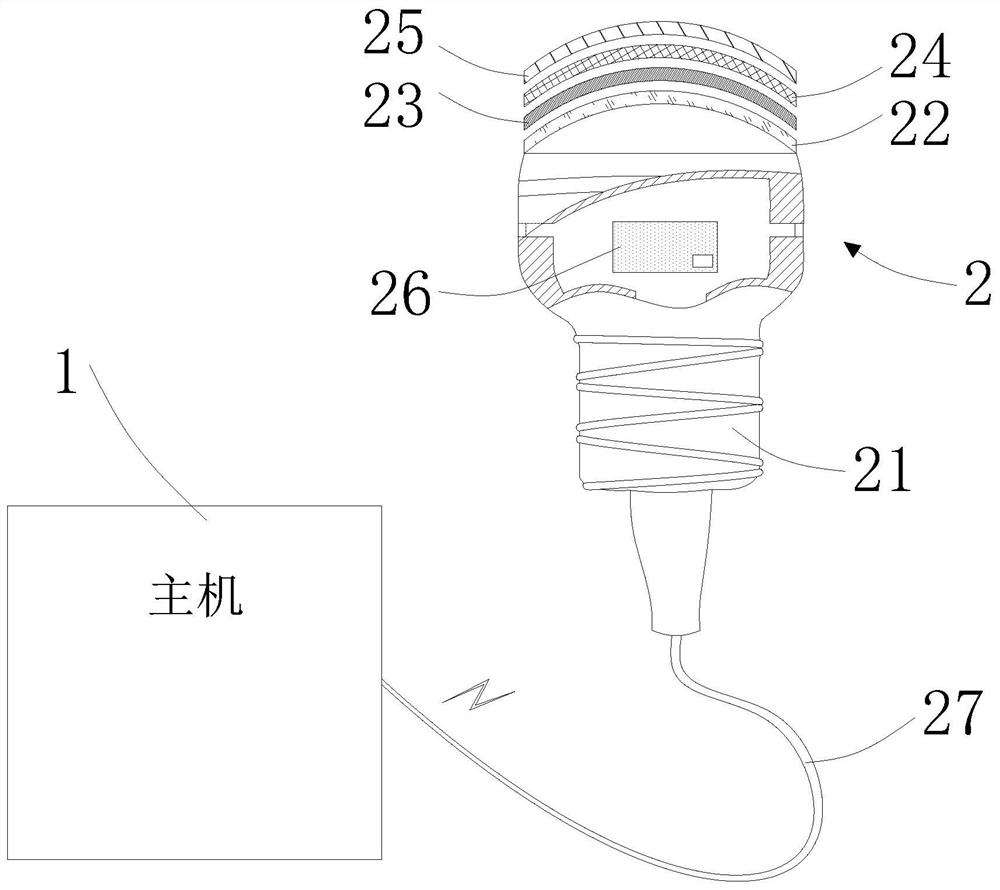

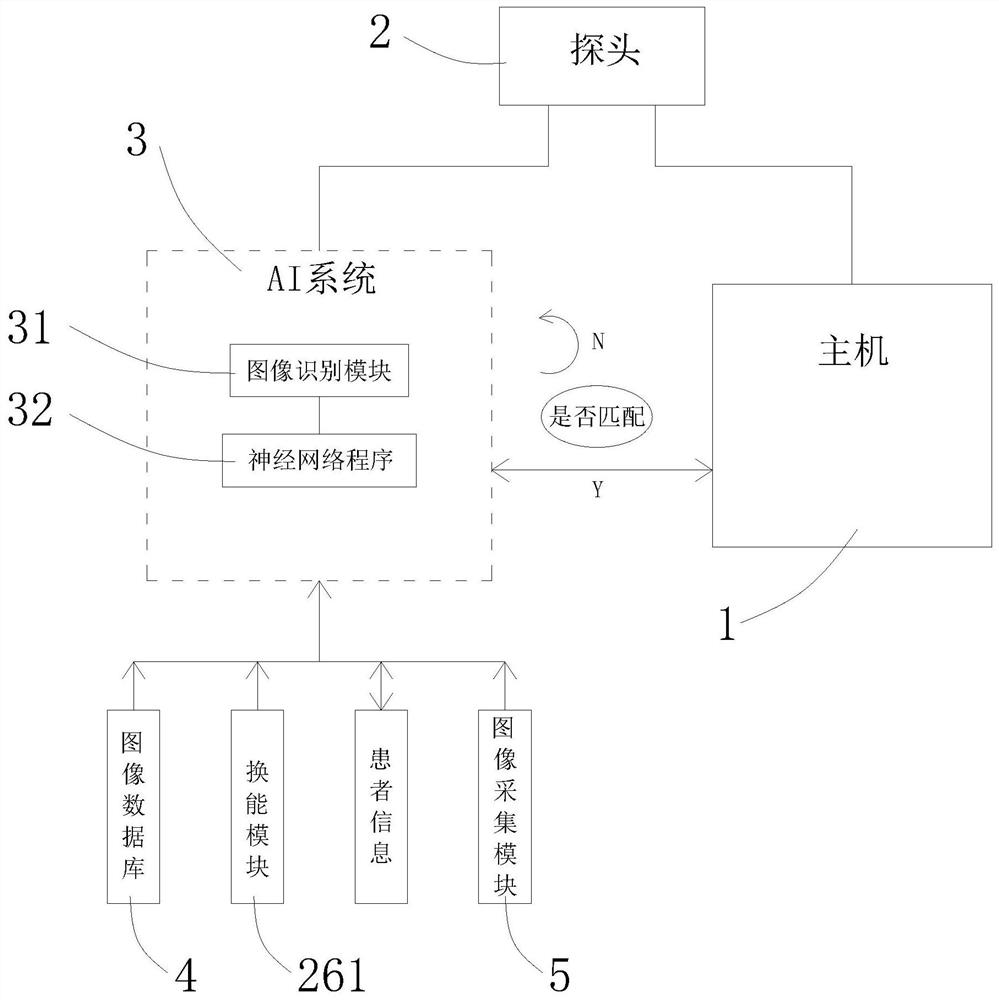

AI identification-based motion joint injury detection device

PendingCN112790790AImprove cooling effectImprove efficiency and lifeOrgan movement/changes detectionInfrasonic diagnosticsEngineeringImage identification

The invention relates to the technical field of medical equipment, and discloses a motion joint injury detection device based on AI identification, the motion joint injury detection device comprises a host, a probe and an AI system, the probe is connected with the host, the probe comprises a crystal layer and a circuit board, the crystal layer vibrates to generate ultrasonic waves, the ultrasonic waves are processed by a conversion module on the circuit board to form electric signals, and the host receives and processes the electric signals to form an image. The probe is provided with the shell, a heat dissipation device is arranged in the shell, the heat dissipation effect of the probe is effectively improved, the use efficiency is improved, and the service life is prolonged. The AI system comprises an image recognition module and an embedded neural network program, the image recognition module is in control connection with the host and a transduction module in combination with the neural network program, so that the transduction module continuously transmits and receives ultrasonic signals for multiple times, the image recognition module verifies the size and type of an image formed by the host, omission of information scanned by the probe is effectively prevented, and the scanning accuracy is improved.

Owner:居天医疗科技(深圳)有限公司

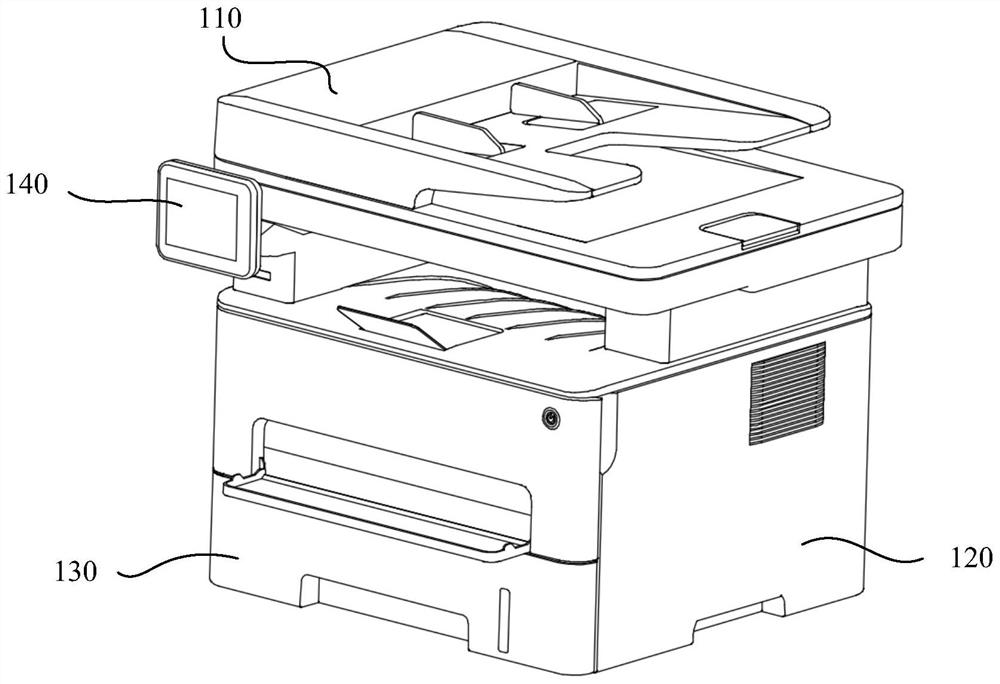

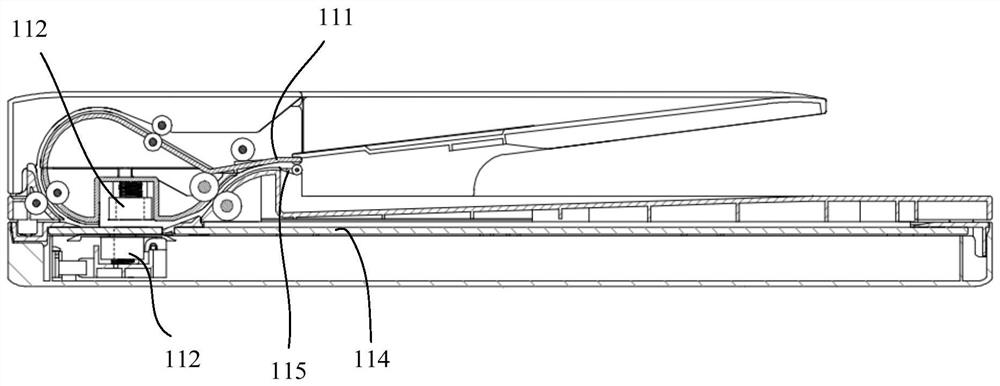

Image processing method, device and image forming device

ActiveCN108156349BCorrect scan errorImprove scan accuracyPictoral communicationImaging processingRadiology

The present invention provides an image processing method, device, and image forming equipment, wherein the image processing method includes: during the shading correction process, acquiring initial correction parameters for performing shading correction on a correction medium, and the correction medium is pasted on the image forming equipment the first side of the glass plate in the middle; acquire the compensation parameters corresponding to the image reading component; the image reading component is set in the image forming device and is located on the second side of the glass plate in the scanning module; according to the compensation parameters The initial correction parameters are compensated to obtain actual correction parameters; during the actual scanning process, the scanned image is corrected according to the actual correction parameters. The image processing method, device and image forming equipment provided by the invention can reduce the imaging chromatic aberration, and further improve the imaging effect.

Owner:ZHUHAI PANTUM ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com