Probe device and scanning method used for aerial flange eddy automatic detection

An automatic detection and disk ring technology, applied in the direction of material magnetic variables, etc., to achieve the effect of convenient disassembly and replacement, ensuring structural rigidity, and reducing detection costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

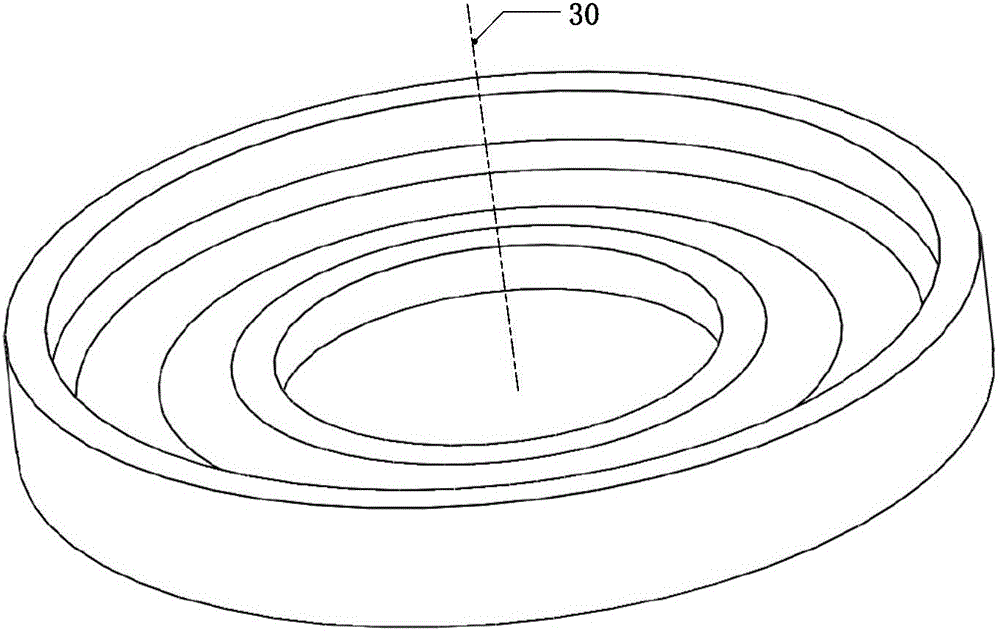

[0046] According to the requirements of technical documents, such as image 3 The entire surface of the aero-engine disc shown is automatically detected by eddy current. The contour line of the cross section of the disc is composed of multiple large-curvature right-angle inner R arcs, straight lines, and ordinary R-arcs, among which the curvature of the large-curvature right-angle inner R arc is The radius is between 9.0mm and 10.5mm. The probe device (consisting of the probe fixture and probe) and the scanning method used for this disc are as follows:

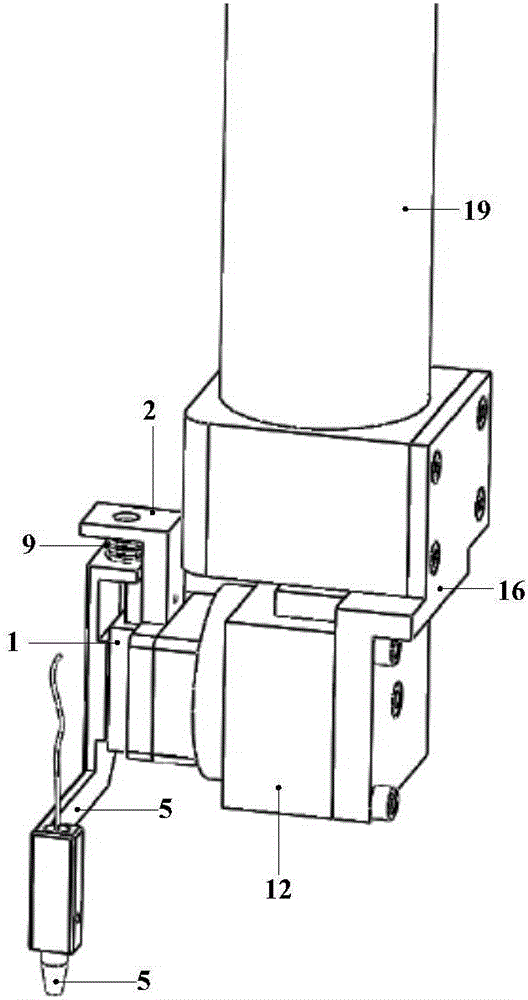

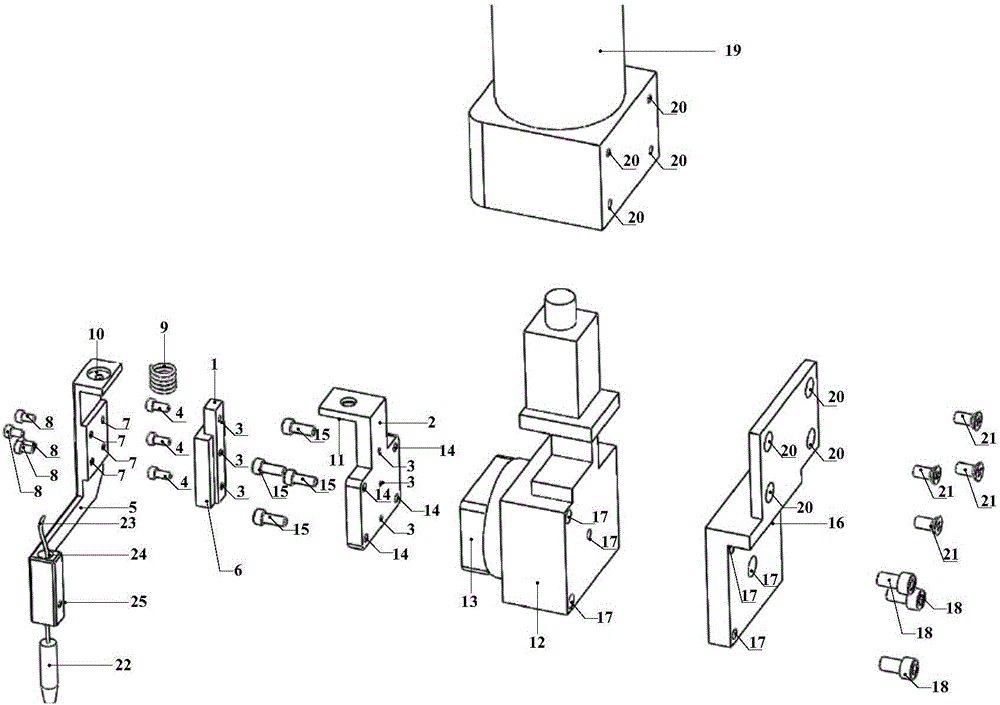

[0047] (1), probe fixture design: such as figure 1 , figure 2 As shown, the probe fixture used is mainly composed of linear slide rail 1, hook connecting plate 2, connecting piece 16, zigzag probe holder 5, electric corner mechanism 12, spring 9, and scanning arm 19. Linear slide rail 1 is zero The pre-tightening force slide rail, the zigzag probe frame 5 is made of aluminum alloy material or a material with similar densit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Stiffness coefficient | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com