Assembly control method and system on assembly line

An assembly control and assembly line technology, applied in the general control system, control/adjustment system, program control, etc., can solve the problems of production efficiency, production progress and product status of the assembly line, which cannot be controlled by the management in real time, information interaction between processes is not smooth, Affect the degree of automation in the manufacturing industry and other issues, to achieve the effect of improving the degree of intelligence and automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

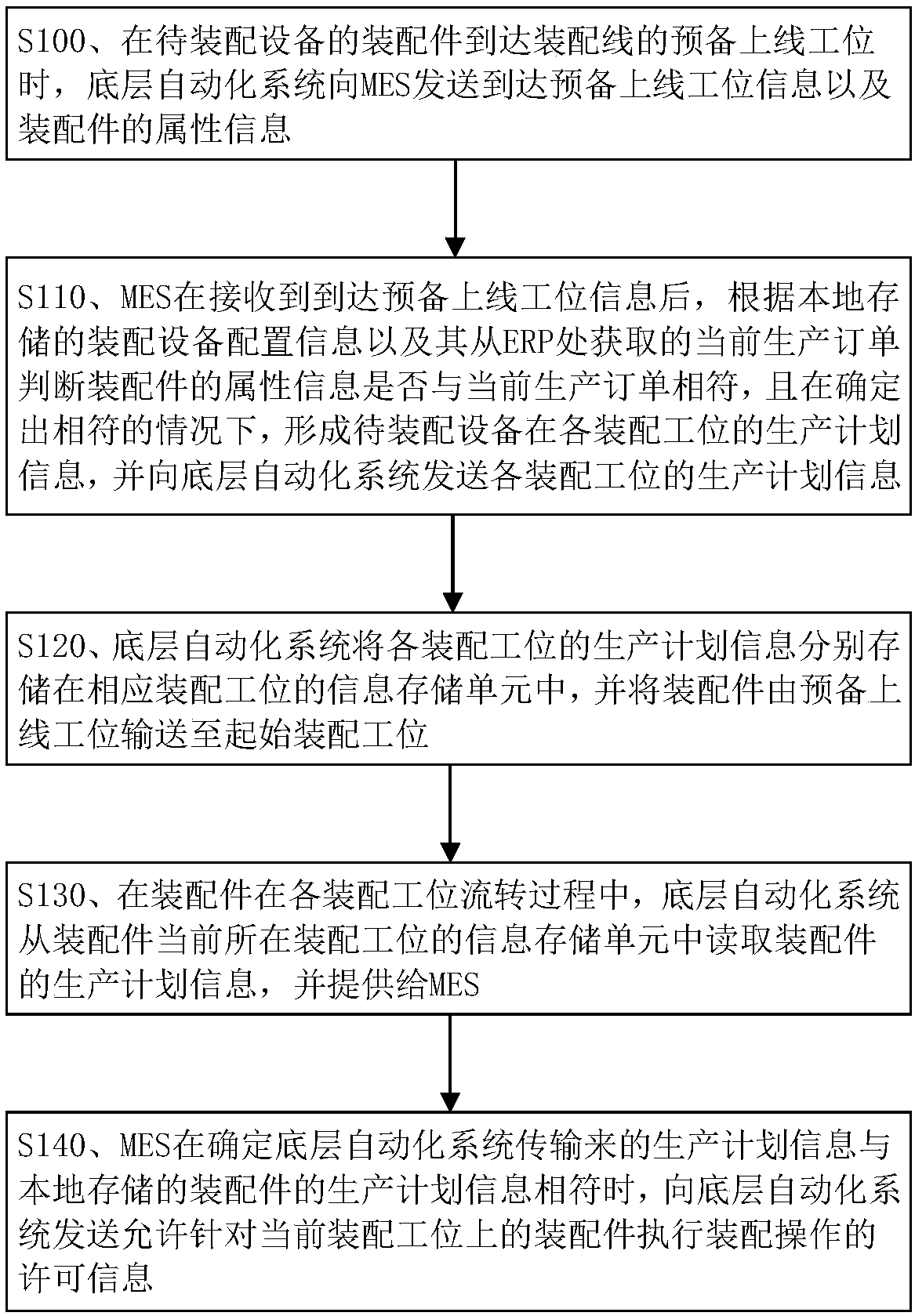

[0014] Embodiment 1. An assembly control method on an assembly line.

[0015] The assembly control method on the assembly line of this embodiment can be realized through information interaction between three-tier systems, wherein the uppermost system is the upper-level production planning management system, the middle-level system is the production and manufacturing management system, and the lowest-level system For the underlying automation system. The upper production planning management system may include computers and servers. The manufacturing management system may include computers and industrial computers. The underlying automation system can include controllers, data collectors, barcodes, various measuring and testing instruments, and manipulators, etc., and the controllers can be realized by PLC (Programmable Logic Controller). For the convenience of expression, in the following description, the upper-level production planning management system is referred to as ERP...

Embodiment 2

[0039] Embodiment 2, an assembly control system on an assembly line.

[0040] The assembly control system on the assembly line in this embodiment includes a three-layer system, wherein the uppermost system is the upper production plan management system, the middle layer system is the production management system, and the lowermost system is the bottom automation system.

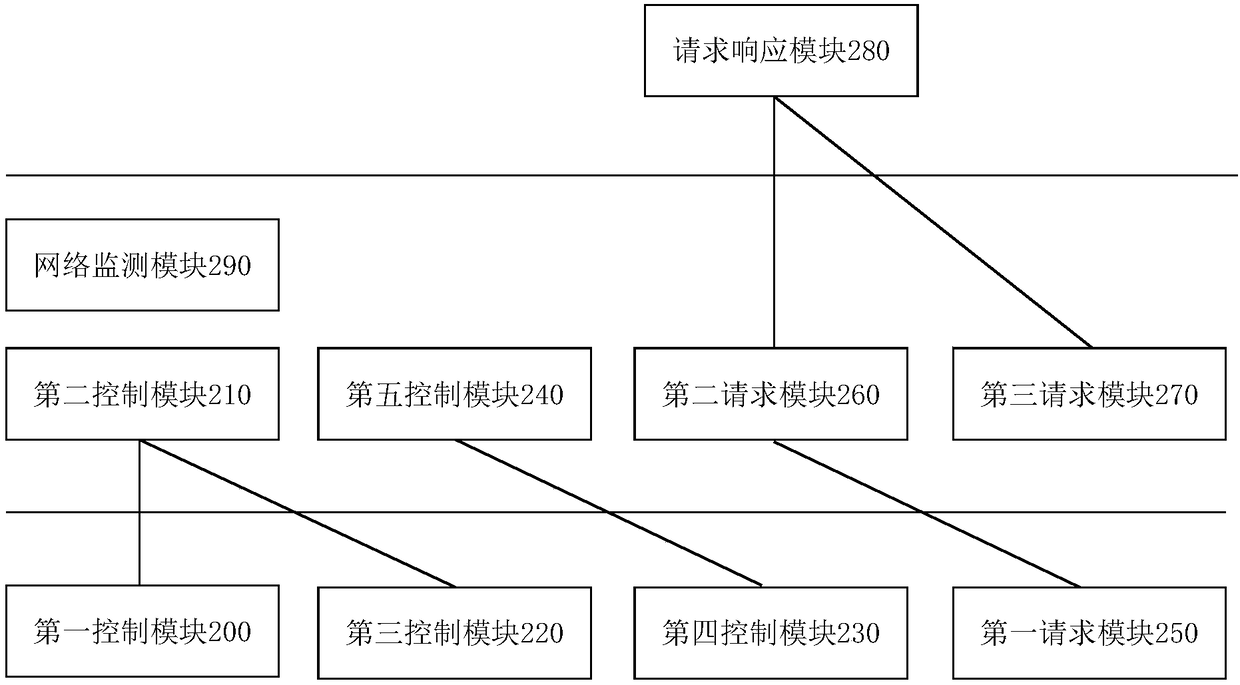

[0041] The structure of the assembly control system on the assembly line of this embodiment is as follows: figure 2 shown. figure 1 The assembly control system shown mainly includes: a first control module 200, a second control module 210, a third control module 220, a fourth control module 230 and a fifth control module 240; optionally, the assembly control system may also include : a first request module 250 , a second request module 260 , a third request module 270 , a request response module 280 and a network monitoring module 290 . Each module is explained separately below.

[0042] The first control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com