Cable traction device for threading pipe and method for laying cable through pipe

A cable traction and pipe technology, applied in cable laying equipment, cable installation devices, cable installation and other directions, can solve problems such as cable damage, secondary rework, hidden dangers, etc., to save working time, save spare parts costs, and extend service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

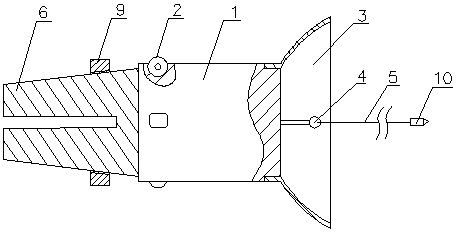

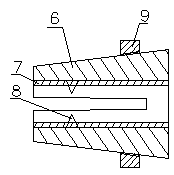

[0023] Such as figure 1 Shown is a cable traction device for threading pipes, including a traction seat 1 and a clamping tube 6 fixed at one end of the traction base 1, the outer circle of the clamping tube 6 is connected with a fastening nut 9 through a tapered thread, and the outer diameter of the clamping tube 6 is The diameter gradually decreases outward from the end face of the traction seat 1, and the small diameter end of the clamping tube 6 is provided with two to four gaps that run through the diameter of the clamping tube 6 and extend to the large diameter end of the clamping tube. In this embodiment, there are four gaps, and the clamping The holding tube wall is divided into four parts evenly. The other end of the traction seat 1 is fixedly provided with a suspension ring 4 and a trumpet-shaped rubber sleeve 3 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com