Method for transforming power supply of coal feeder

A coal feeder and power supply technology, which is applied in the field of basic engineering, can solve problems such as relay coil power failure and coal feeder tripping, and achieve the effects of reducing the rate of malfunction, improving reliability, and avoiding coal feeder tripping accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

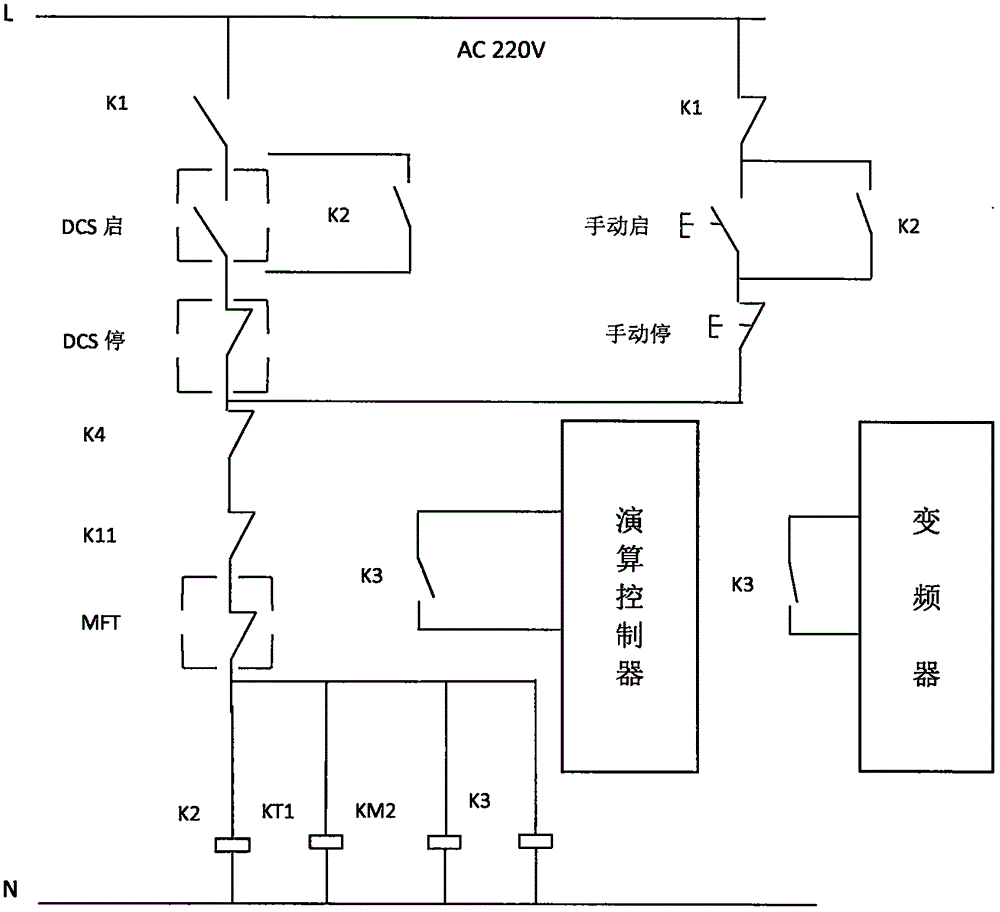

[0007] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0008] The complete steps of the inventive method:

[0009] 1. Add a delay relay KY1 in the control circuit of the coal feeder, and set the delay time to 1S;

[0010] 2. Change the operation feedback from the normally open contact of the original K2 relay to the normally open contact of the delay relay KY1;

[0011] 3. Change the self-holding contact to two parallel connections, which are the normally open contact of the original K2 relay and the normally open contact of the delay relay KY1;

[0012] 4. Connect the electricity of the relay K3 coil to the normally closed contact of the self-holding relay K2, and the electricity of the normally closed contact of the relay K2 is directly taken from the outlet of the quick cut device;

[0013] 5. Change the normally open contacts of the three pairs of relay K3 to the coal feeder inverter, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com