Disc type ironless flux modulation motor

A magnetic flux modulation, ironless technology, applied to synchronous motors with stationary armatures and rotating magnets, electrical components, electromechanical devices, etc. Advanced problems, to achieve the effect of eliminating poor mechanical performance, improving motor efficiency, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

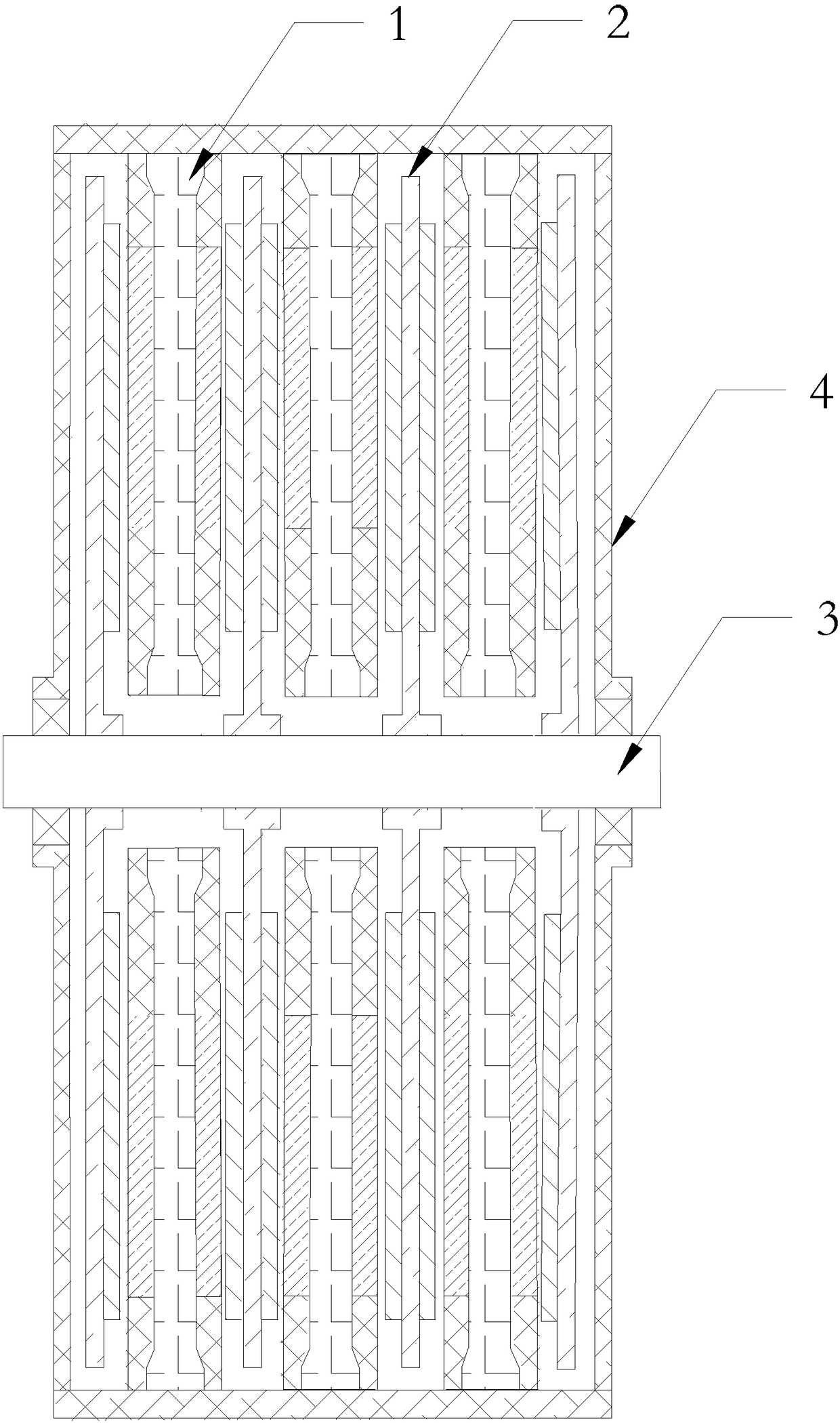

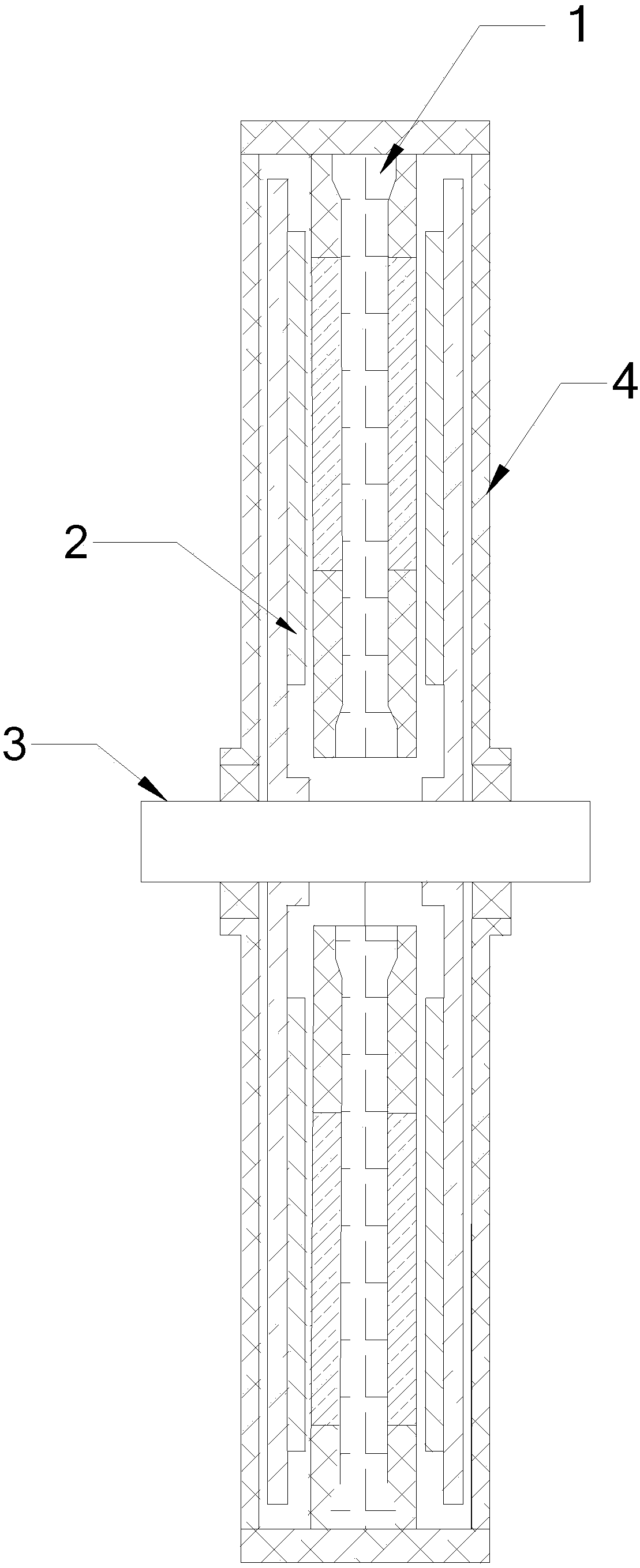

[0023] Specific implementation mode one: see Figure 1 to Figure 7 Describe this embodiment, the disk-type ironless flux modulation motor described in this embodiment, it includes N stators 1, N+1 rotor discs 2, rotating shaft 3 and housing 4, N stators 1 and N +1 rotor discs 2 are located in the housing 4, N stators 1 are fixed on the inner wall of the housing 4, N+1 rotor discs 2 are rotationally connected with the rotating shaft 3 through interference fit, and N stators 1. N+1 rotor discs 2 are coaxial with housing 4, N stators 1 and N+1 rotor discs 2 are arranged alternately, and there is an air gap between stator 1 and rotor discs 2; N is greater than or equal to an integer of 1;

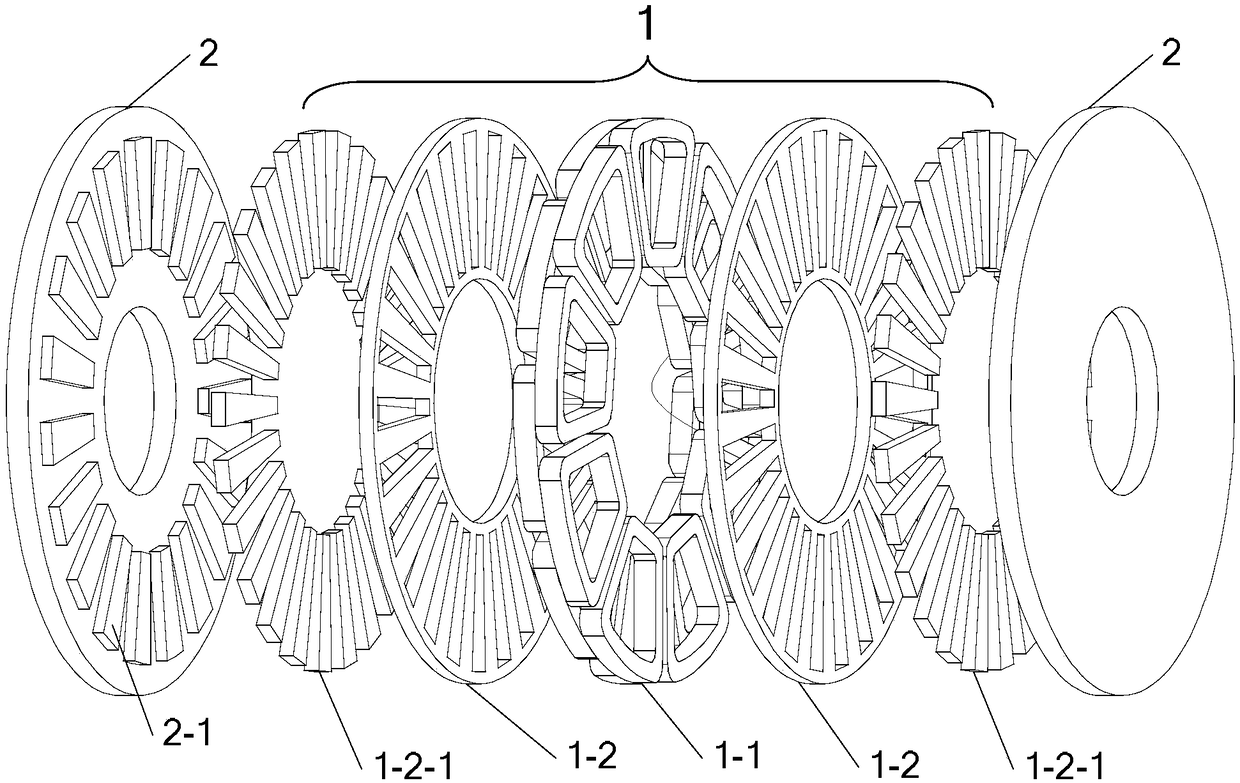

[0024] Each stator 1 includes a set of windings 1-1 and two non-magnetically conductive armature disks 1-2, and the annular winding 1 is packaged between the two non-magnetically conductive armature disks 1-2.

[0025] N s grooves, N s The grooves are evenly distributed along the circumfere...

specific Embodiment approach 2

[0034] Specific implementation mode two: see Figure 1 to Figure 7 To describe this embodiment, the difference between this embodiment 1 and the disk-type coreless flux modulation motor described in Embodiment 1 is that the non-magnetically conductive armature disk 1 - 2 is an epoxy resin armature disk.

[0035] In this embodiment, each non-magnetically conductive armature disc 1-2 is provided with N s grooves, N s The grooves are evenly distributed along the circumference of the non-magnetically conductive armature disc 1-2, and each groove is provided with a magnetic modulation block 1-2-1; epoxy resin is non-magnetically conductive, and can be regarded as , The magnetically conductive material and the nonmagnetically conductive material are arranged at intervals on the non-magnetically conductive armature disc 1-2 to achieve the magnetic flux modulation effect.

[0036] The non-magnetically conductive armature disc 1-2 can be directly cast from epoxy resin, and has relati...

specific Embodiment approach 3

[0037]Specific implementation mode three: see Figure 1 to Figure 7 This embodiment is described. The difference between this embodiment and the disk-type coreless flux modulation motor described in Embodiment 1 or Embodiment 2 is that the material property of the magnetic modulation block 1-2-1 is ferromagnetic.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com