Feeding and paint mist recovery protective cover system of ship shell plate towing spraying type robot and operation method of feeding and paint mist recovery protective cover system

A protective cover, robot technology, applied in the direction of the spray device, etc., can solve the problems of pollution, damage to the coated area, and warping of the dragging pipeline.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The structure of the present invention will be further described below with reference to the accompanying drawings.

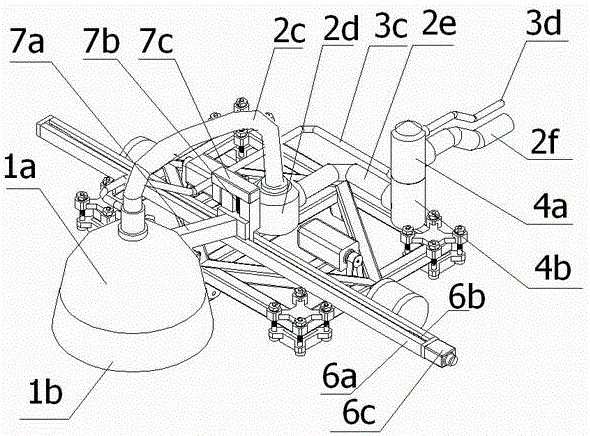

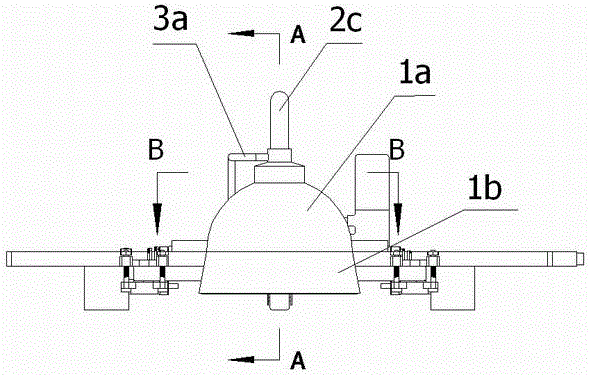

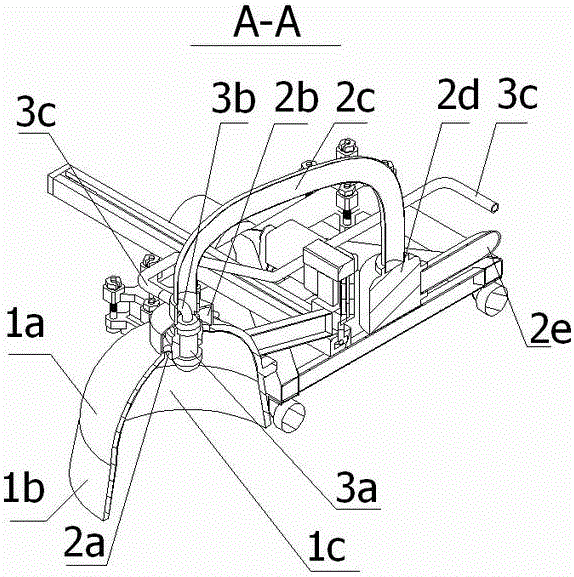

[0022] figure 1 , 2, 3, 4, 5, 6, 7, and 8 show the structural diagrams of the material supply and paint mist recovery protective cover system of the drag coating robot for the outer plate of the ship. The system is mainly composed of spraying and protective cover part, spraying material supply part, paint mist vacuum recovery part, drag pipeline anti-bending moment and winding part, etc. The spraying and protective cover part is embedded in the center of the paint mist protective cover 1a by the paint nozzle 3a, and the paint mist protective outer cover 1b is connected to the outside of the paint mist protective cover 1a to form an integral protective cover. The material of the overall protective cover is made of hard plastic. Affected by sudden external force loads such as strong winds when the robot is working, the protective cover is set in a circul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com