A bus-based tension-free rubber winding control system and its control method

A control system and control method technology, applied in the direction of winding strip, function indication, thin material processing, etc., can solve the problems of large slip, the tail winding cannot work normally, etc., so as to reduce the installation space and reduce mutual interference. , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

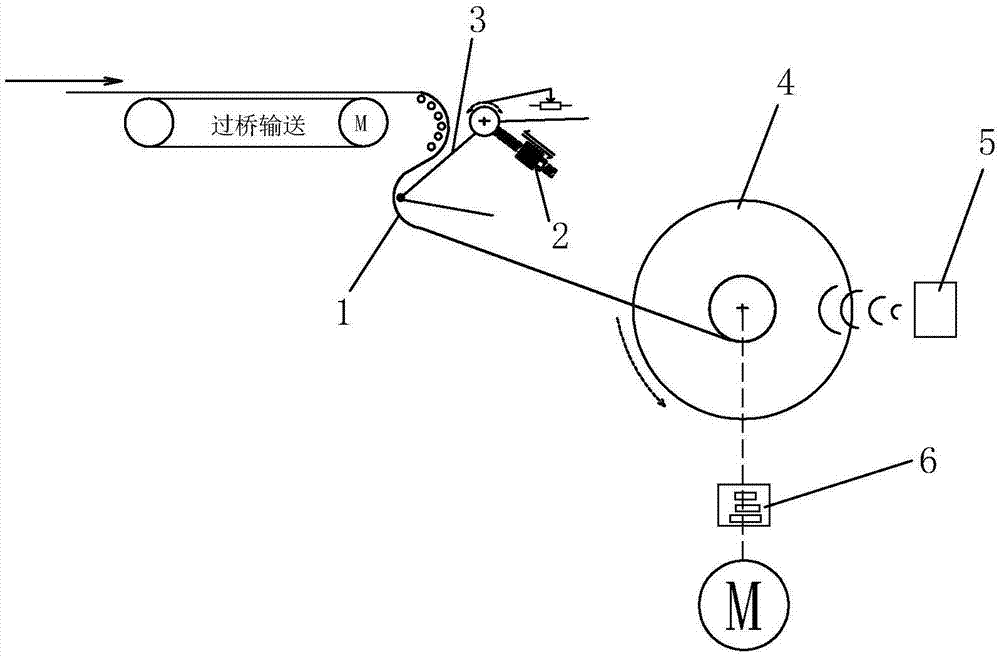

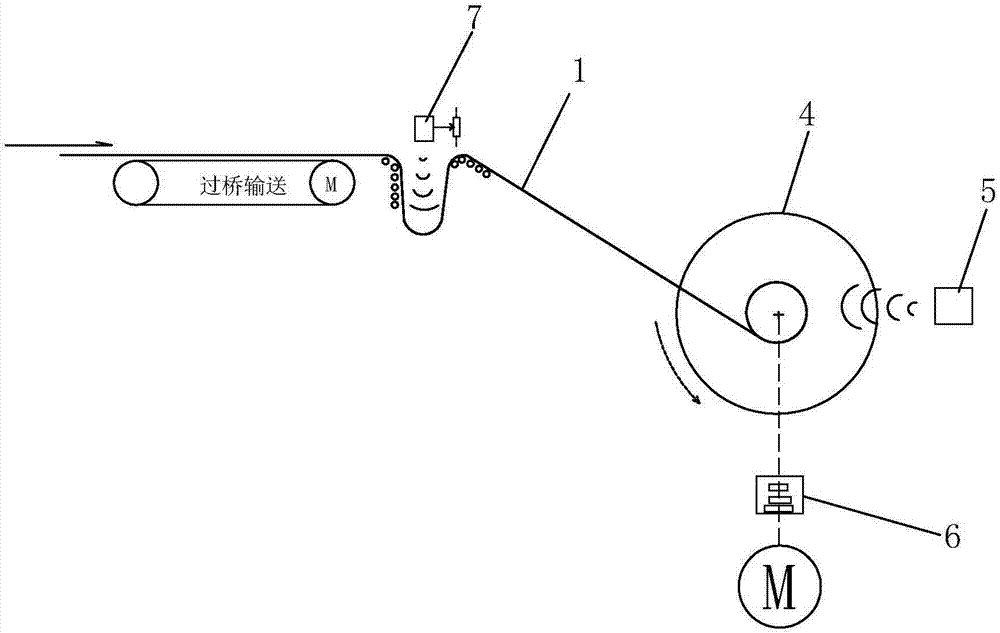

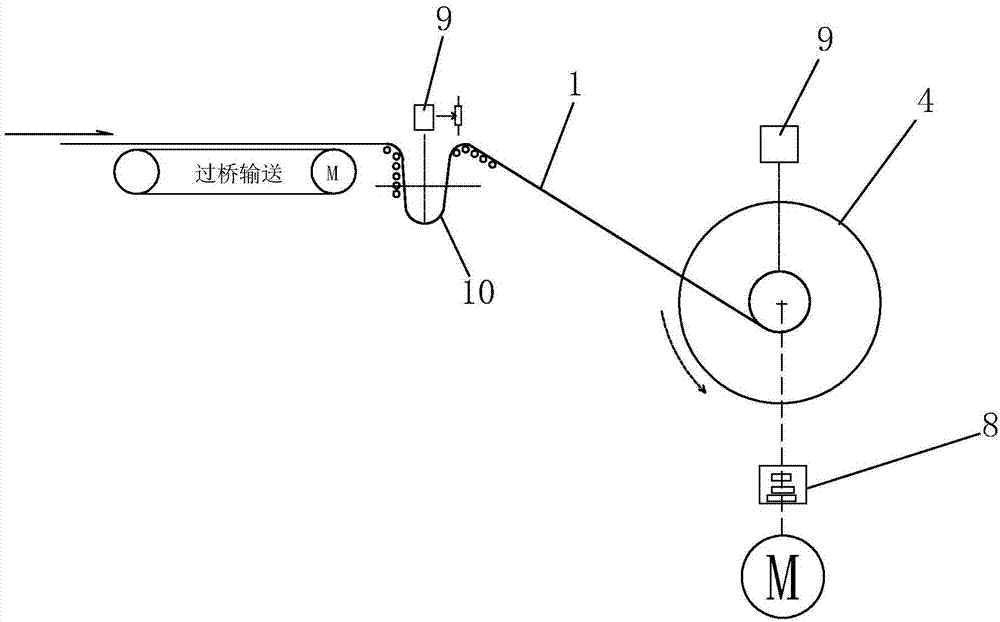

[0033] Such as image 3 , Figure 4 As shown, the present invention is a bus-based tension-free rubber winding control system, including a PLC control system, an operation panel, two laser measuring sensors, and two vector frequency converters. The PLC control system includes CPU module, DC24V DC power supply module, real-time industrial Ethernet bus, and analog input module. The CPU module is connected with DC24V DC power supply module and real-time industrial Ethernet bus respectively. And operation panel connection, analog input module is also connected with real-time industrial Ethernet bus. One of the laser measurement sensors is set above the U-shaped single ring, and the laser measurement sensor is installed at the center above the U-shaped single ring during installation, and the other laser measurement sensor is set above the winding wheel. Installed at the center above the winding wheel, the output ends of the two laser measurement sensors are respectively connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com