Washing machine

A washing machine and washing tub technology, applied in the field of washing machines, can solve the problems of dirt storage, bacteria breeding, and the inability to disassemble and clean the inner and outer tubs, so as to save materials, save water, and avoid the growth of bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

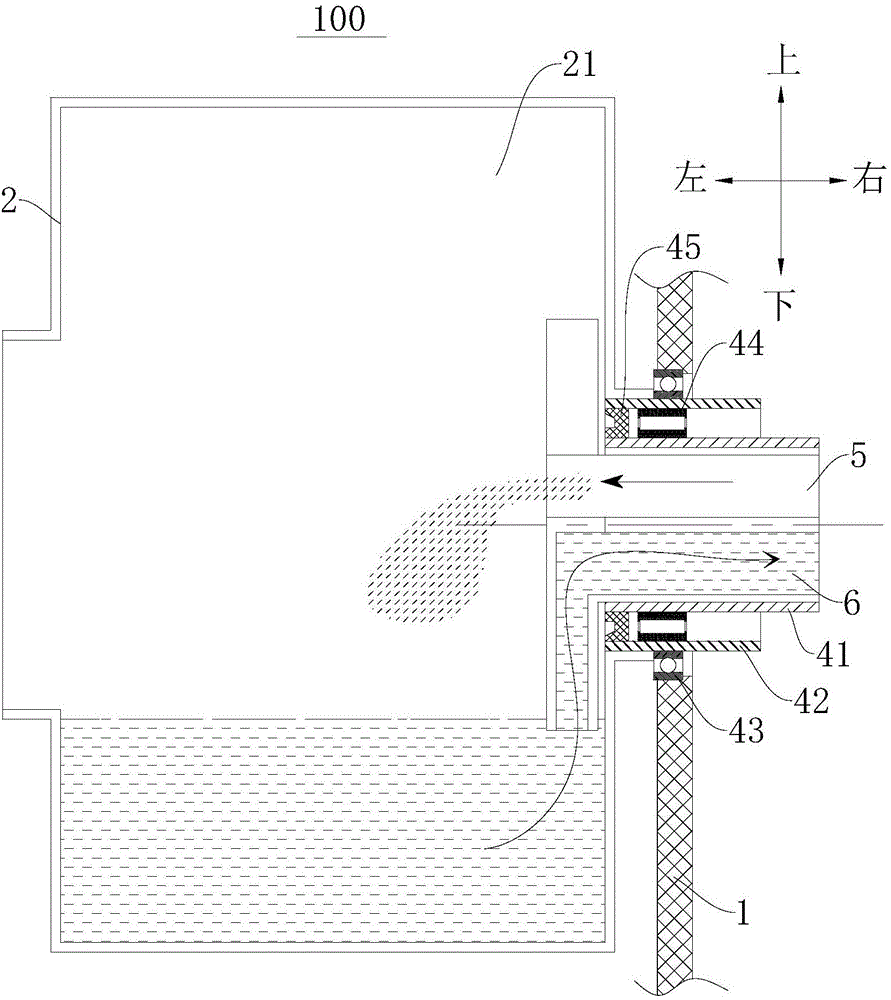

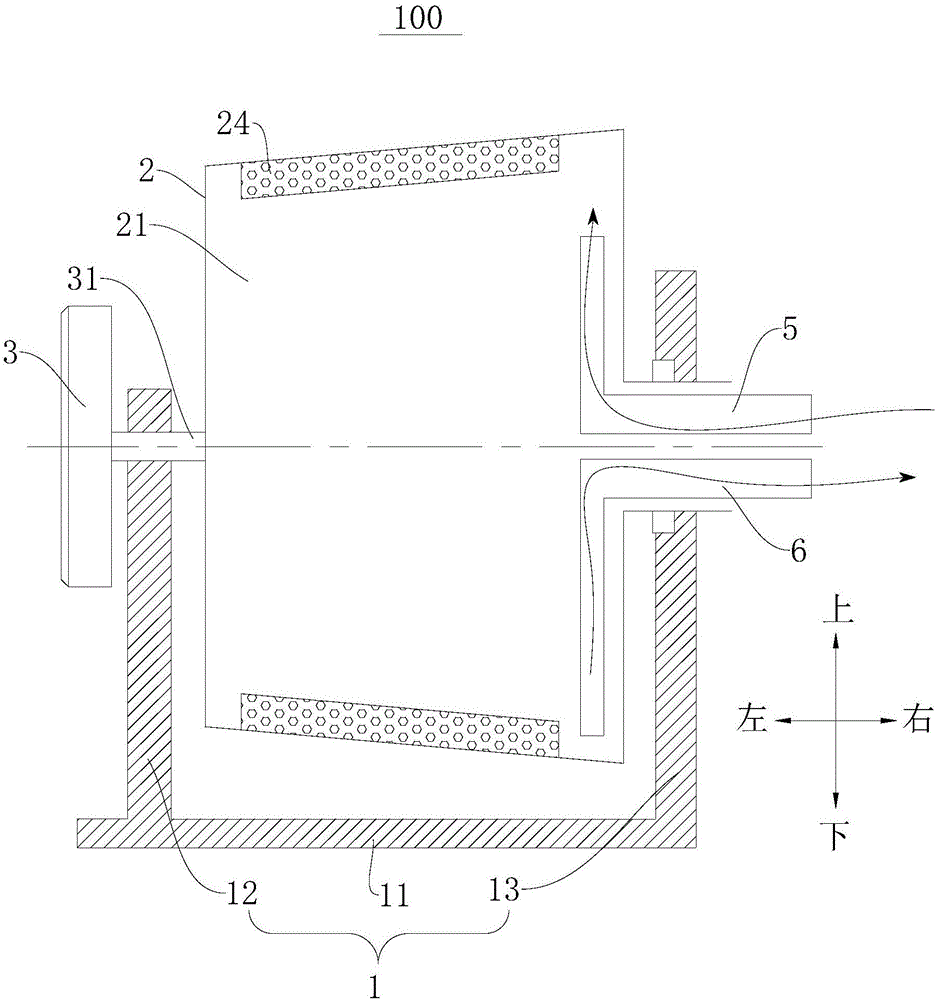

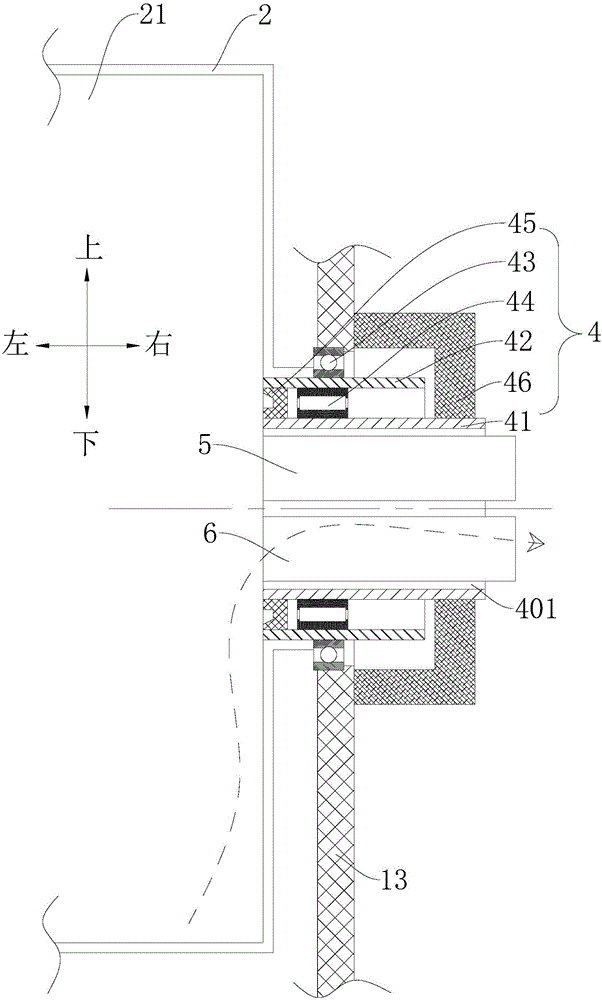

[0117] refer to figure 1 , the washing machine 100 includes a base 1 , a washing tub 2 , a driving member 3 , a support assembly 4 , a water inlet pipe 5 , a drain pipe 6 , a heating device 7 , a pump 8 and a locking device 9 .

[0118] Specifically, such as figure 1 As shown, the base 1 may include: a bottom plate 11, a first bracket 12 and a second bracket 13, wherein the first bracket 12 and the second bracket 13 extend along the up-down direction and are arranged at intervals along the left-right direction on the bottom plate 11, washing The tub 2 is rotatably provided between the first bracket 12 and the second bracket 13 .

[0119] The washing bucket 2 is a hollow column extending along the left and right direction. A washing cavity 21 is formed in the washing bucket 2, and the left end of the washing bucket 2 is closed and a through hole is formed in the center of the right end. In the direction from left to right, the washing bucket The diameter of the washing tub 2 ...

Embodiment 2

[0135] The structure of this embodiment is substantially the same as that of Embodiment 1, wherein the same components use the same reference numerals, the difference is only that: the washing machine 100 in Embodiment 1 includes a pump 8 and a heating device 7, while in Embodiment 2 The washing machine 100 described above only includes a heating device 7 and does not include a pump 8. The heating device 7 is arranged outside the washing tub 2 and only heats the water flowing through the water inlet pipe 5 when the water enters.

Embodiment 3

[0137] The structure of this embodiment is substantially the same as that of Embodiment 1, wherein the same components use the same reference numerals, the only difference is that: the washing machine 100 in Embodiment 1 includes a pump 8 and a heating device 7, and the heating device 7 is set Outside the washing tub 2, the washing machine 100 in the third embodiment only includes the heating device 7 and does not include the pump 8, and the heating device 7 is arranged inside the washing tub 2 for directly heating the water in the washing chamber 21 . And the heating power line 71 of the heating device 7 passes through the pipeline channel 401 and extends out of the washing chamber 21 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com