drying system

A drying system and post-drying technology, applied in the field of drying systems, can solve the problems of longer drying time, slow heating speed, low energy efficiency, etc., and achieve the effect of shortening the drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

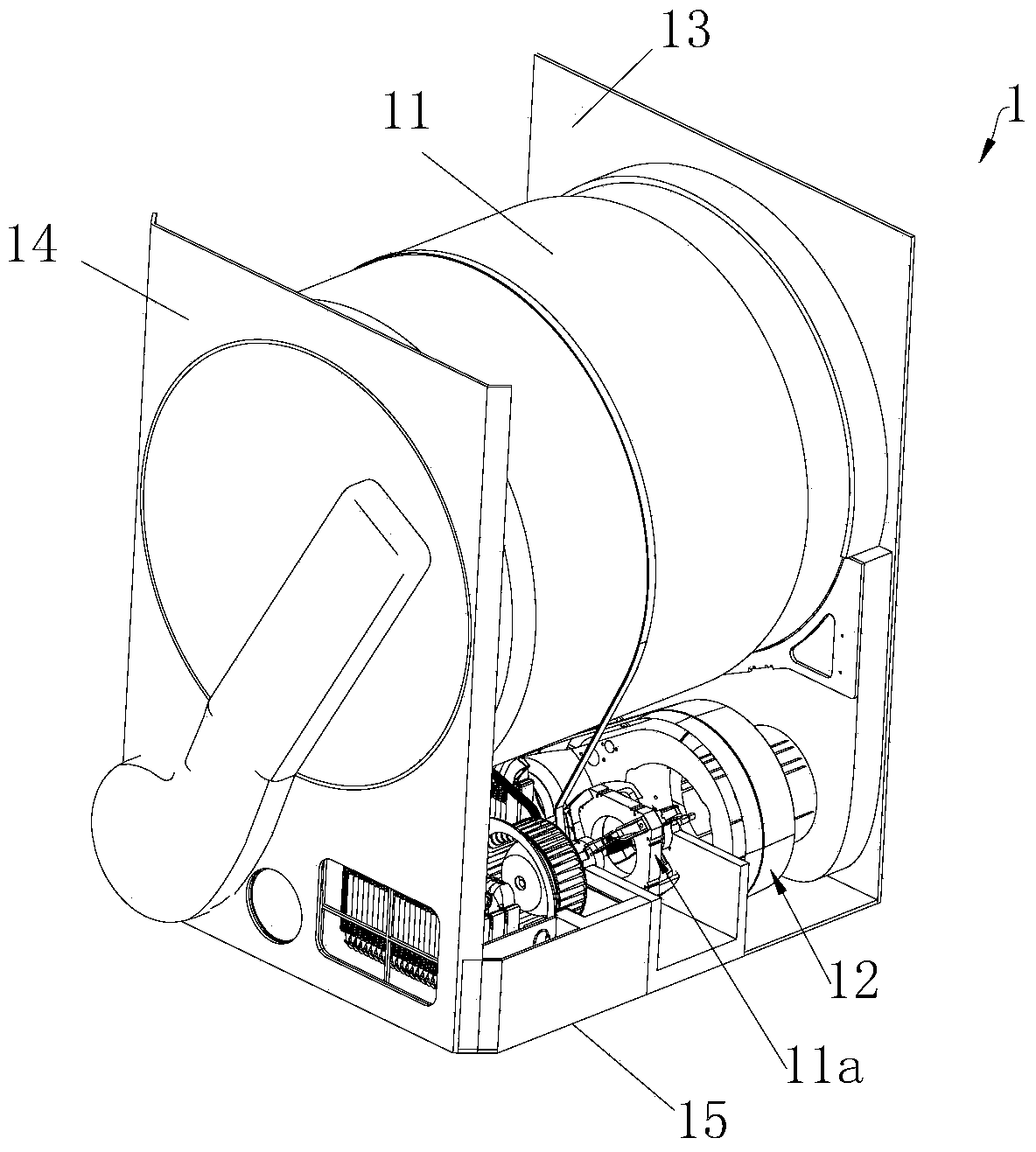

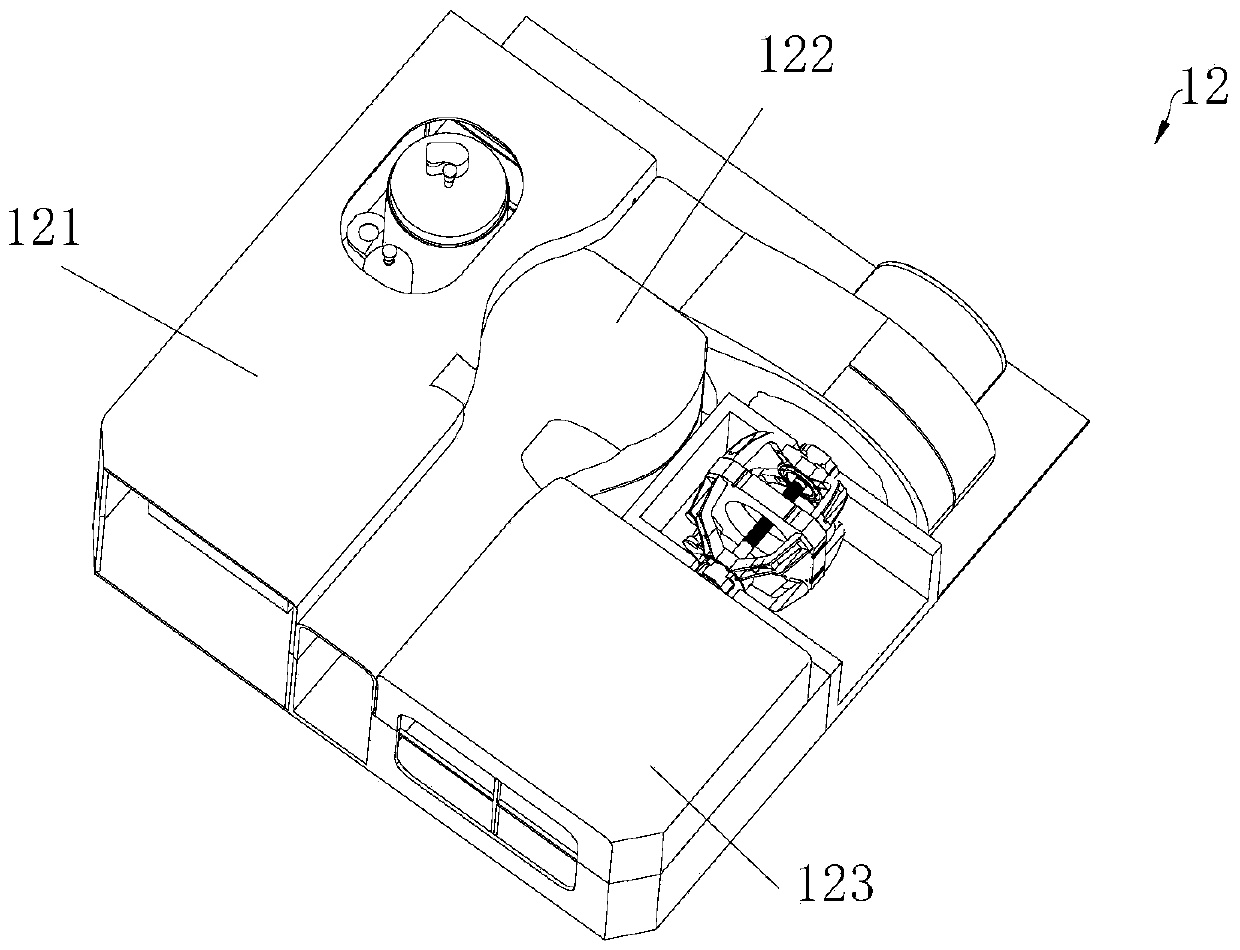

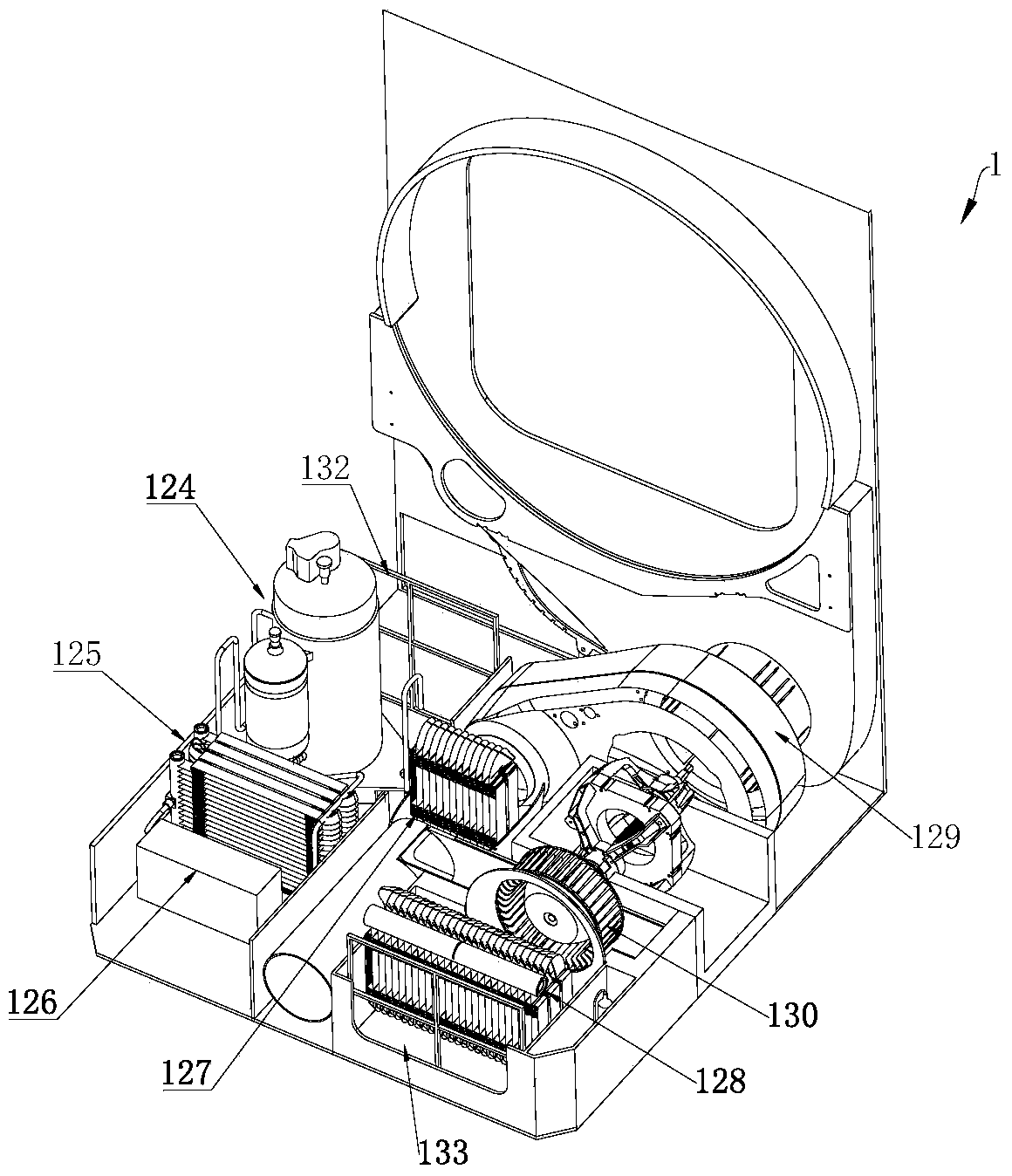

[0035] refer to Figure 1-4 In this embodiment, the drum is used as a drying container as an example for illustration. The clothes dryer 1 includes a cabinet, a drum 11 disposed inside the cabinet, a drying system 12, and a motor 11a for driving the drum 11 to rotate. The body includes a front wall portion 13, a rear wall portion 14 and a bottom 15, the front wall portion 13 is arranged opposite to the rear wall portion 14, the bottom 15 is defined as the space below the drum 11 of the above-mentioned box body, and the drying system 12 Located at the bottom 15 of the box body, the drum 11 is formed with a front side and a rear side correspondingly, the box body is provided with an opening door for opening or closing the front side of the drum 11, and the front side of the drum 11 is assembled and connected with the front wall portion 13 of the box body, The rear side of the drum 11 is assembled and connected with the rear wall portion 14 of the box.

[0036]The drying system ...

Embodiment 2

[0046] refer to Figure 6 , 7 , the drying system of this embodiment is substantially the same as the drying system described in Embodiment 1, the only difference lies in the refrigerant circulation system 300'. refer to Figure 7 The heat absorption unit of the refrigerant circulation system 300' in this embodiment includes a heat absorption module 127 and a heat absorption device 128 arranged in parallel. The heat absorption module 127 of the heat absorption unit is used to absorb the heat of the air in the air passage after drying. , the heat absorption device 128 is used to absorb heat from the indoor air environment, wherein the heat absorption device 128 is a first evaporator, and the heat absorption module 127 is a second evaporator. In this embodiment, the drying system further includes a second throttling device 131', a pressure regulating valve 135, and a flow divider 136. The flow divider 136 is arranged on the second heating device 125 and the heat absorption mod...

Embodiment 3

[0050] refer to Figure 8 , 10 , the drying system of this embodiment is substantially the same as the drying system described in Embodiment 1, the difference is that the heat absorbing module 127' of this embodiment includes a heat absorbing part and a heat releasing part, and the heat absorbing part and the heat releasing part The heat transfer between parts can be realized; the heat absorbing part is located in the air passage after drying to absorb the heat of the air, and transfers the heat to the heat releasing part; the heat releasing part is located in the air passage before drying, along the drying front In the extending direction of the air channel of the air channel, the heat radiation part is located between the first heating device 124 and the second heating device 125 , and the air 202 heated by the first heating device 124 flows through the heat radiation part for reheating. The heat absorption module 127' of this embodiment is, for example, a cross-flow heat e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com