Anti-oxidation system for molten aluminum in furnace

An oxidation system and technology of molten aluminum, applied in furnaces, charge materials, crucible furnaces, etc., can solve the problems of anti-oxidation of molten aluminum, save costs, improve physical properties and quality, and reduce the amount of inflow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

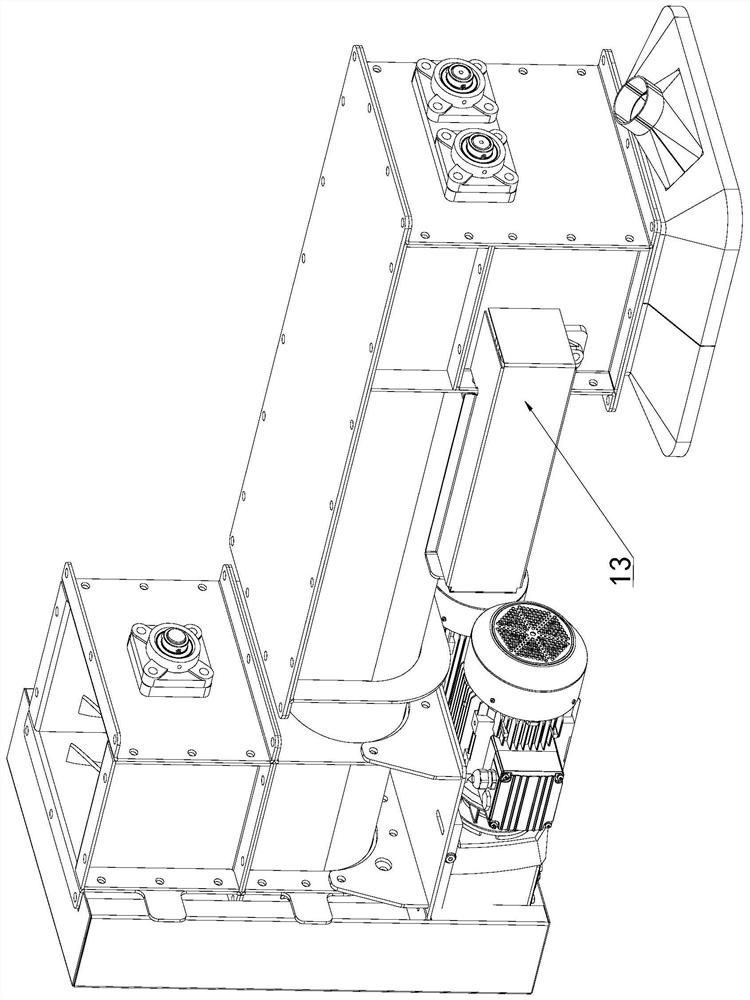

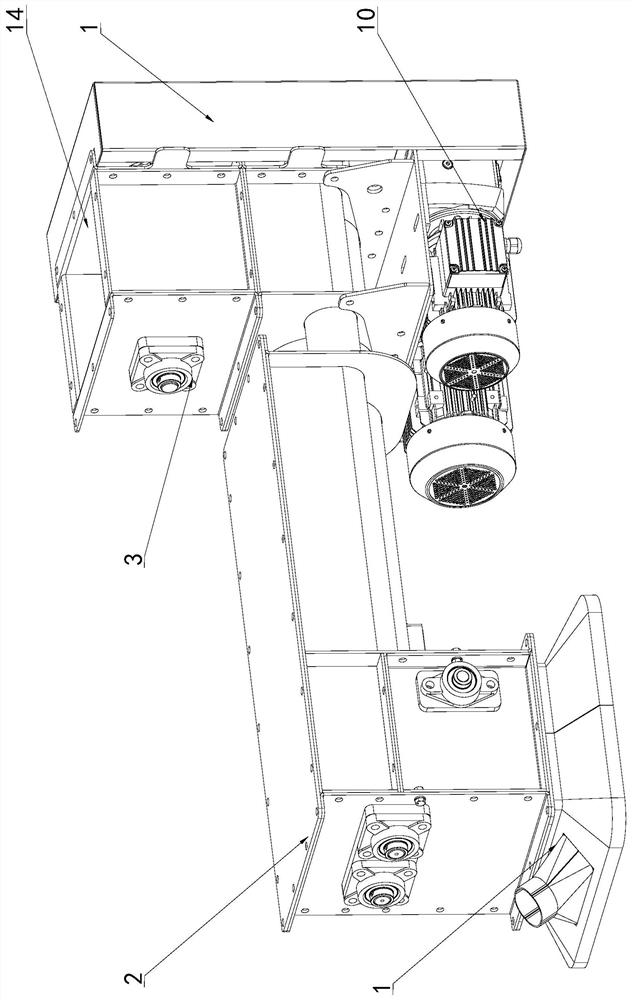

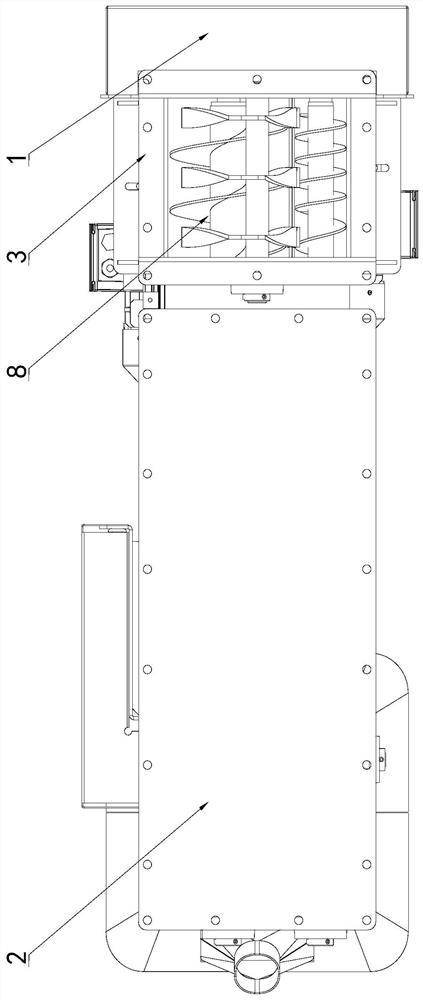

[0030] Such as Figure 1~4 An anti-oxidation system for molten aluminum in a furnace is shown, which includes a mounting frame 1 and a melting furnace body arranged on the mounting frame 1; the melting furnace body includes an upper furnace body 2 and the upper furnace body 2 A connected lower furnace body 3; the upper furnace body 2 is located above the lower furnace body 3; a first cavity is provided in the lower furnace body 3; The partition 4 for the lifting movement of the installation frame 1; the partition 4 divides the first cavity into a compression space arranged up and down and isolated from each other and a liquid storage space 5 for storing aluminum liquid; the partition 4 An air layer 6 is formed between the aluminum liquid, and the position corresponding to the air layer 6 on the lower furnace body 3 is provided with an air inlet and an exhaust port, and the air inlet is connected to the external connection for conveying inert gas. The device is connected.

[...

Embodiment 2

[0039] The second embodiment is a further description of the above embodiments. It should be understood that this embodiment includes all the aforementioned technical features and is further specifically described as:

[0040] Such as Figure 1~4An anti-oxidation system for molten aluminum in a furnace is shown, which includes a mounting frame 1 and a melting furnace body arranged on the mounting frame 1; the melting furnace body includes an upper furnace body 2 and the upper furnace body 2 A connected lower furnace body 3; the upper furnace body 2 is located above the lower furnace body 3; a first cavity is provided in the lower furnace body 3; The partition 4 for the lifting movement of the installation frame 1; the partition 4 divides the first cavity into a compression space arranged up and down and isolated from each other and a liquid storage space 5 for storing aluminum liquid; the partition 4 An air layer 6 is formed between the aluminum liquid, and the position corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com