Photoelectric system for yarn defect detection

A technology of optoelectronic system and detection system, which is applied in measurement devices, optical testing of flaws/defects, material analysis by optical means, etc., can solve the problems of high detection cost, yarn interference, complex structure, etc., and achieve a large detection field of view. , the effect of solving false detection and simple system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

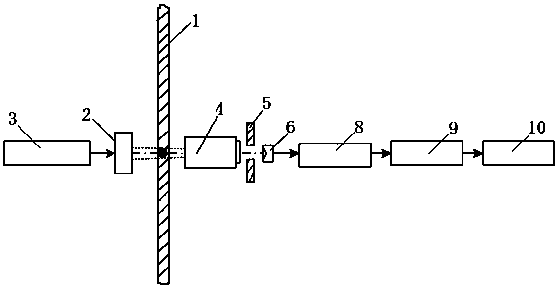

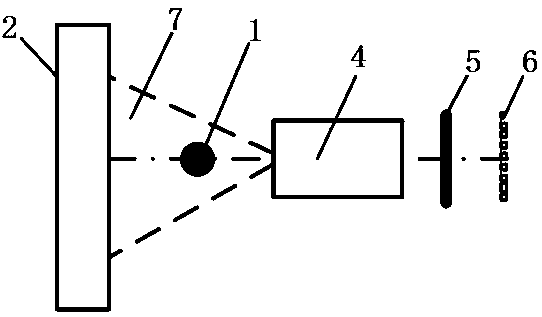

[0015] Below in conjunction with accompanying drawing, the present invention is further described, with reference to figure 1 and figure 2 Shown is a photoelectric system for yarn defect detection, which is set on both sides of the tested yarn 1, including a background light source system set on one side of the tested yarn 1 and a background light system set on the other side of the yarn Defect detection system; the background light source system and the defect detection system are on the same level; the background light source system includes a background light source screen 2 and a light source controller 3 connected with the background light source screen 2, the brightness and color of the background light source screen 2 It can be adjusted so that the yarn under test 1 falls into the background light source to highlight the defects on the yarn under test 1; the defect detection system includes an optical system 4 adjacent to the yarn under test, along which the optical sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com