Frequency converter with automatic temperature control and heat radiation function

An automatic temperature control and frequency converter technology, applied in temperature control, non-electric variable control, instruments, etc., can solve the problems of uneven and insufficient heat dissipation of frequency converters, reduce failure rates, improve heat dissipation, and ensure normal operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

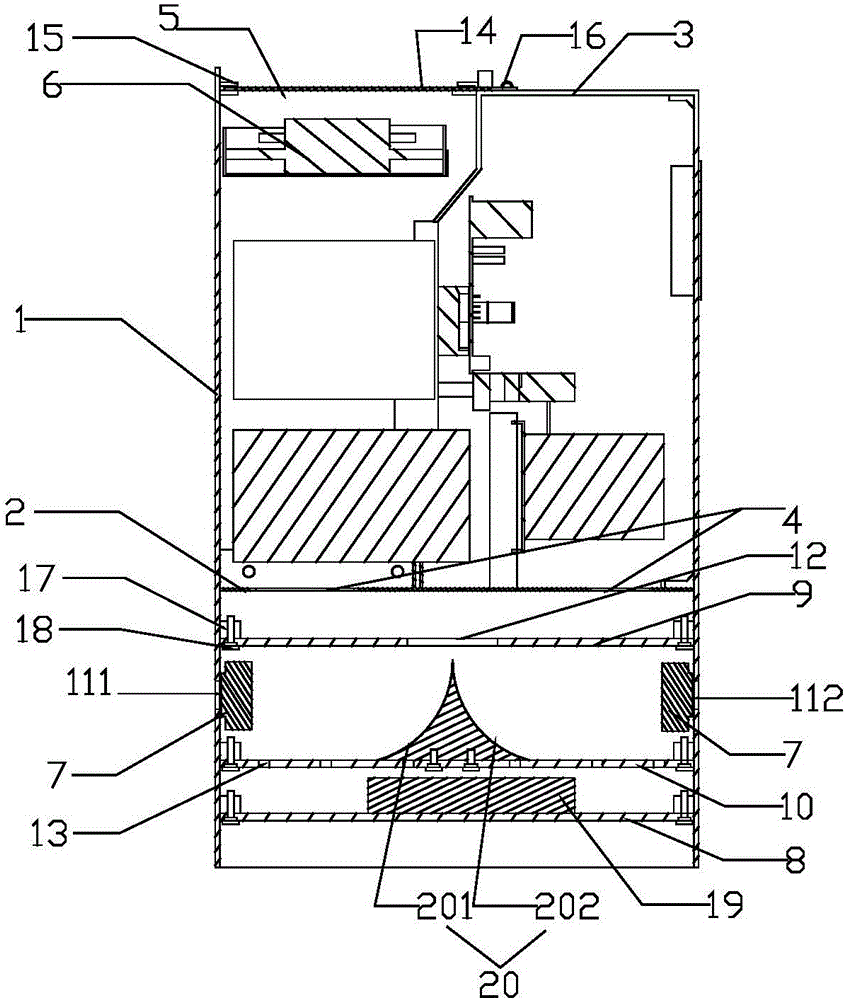

[0017] The present invention will be further described below in conjunction with drawings and embodiments.

[0018] As shown in the figure, the waterproof and dustproof frequency converter of this embodiment includes a control cabinet 1, an air inlet 4 is arranged on the bottom plate 2 of the control cabinet 1, an air outlet 5 is arranged on the top plate 3 of the control cabinet 1, and an air outlet 5 is arranged on the top plate 3 of the control cabinet 1. The tuyere 5 is provided with an axial flow fan 6, an upper partition 9 and a lower partition 10 are arranged on the lower part of the bottom plate 2 from top to bottom, between the upper and lower partitions, inlet Air hole 11, air inlet 11 places are equipped with cold wind device 7, and cold wind device 7 is electrically connected with cold wind device controller 19, and cooling device controller 19 is installed on the sealing plate 8, is also electrically connected with cooling device controller 19 A temperature sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com