Integrated tail gas and waste powder treating apparatus of complete set of equipment for regeneration and stirring of asphalt

A technology for asphalt regeneration and complete equipment, which is applied in the direction of combined devices, chemical instruments and methods, and separation of dispersed particles, which can solve problems such as high cost and complex structure of processing equipment, and achieve the effect of small investment and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

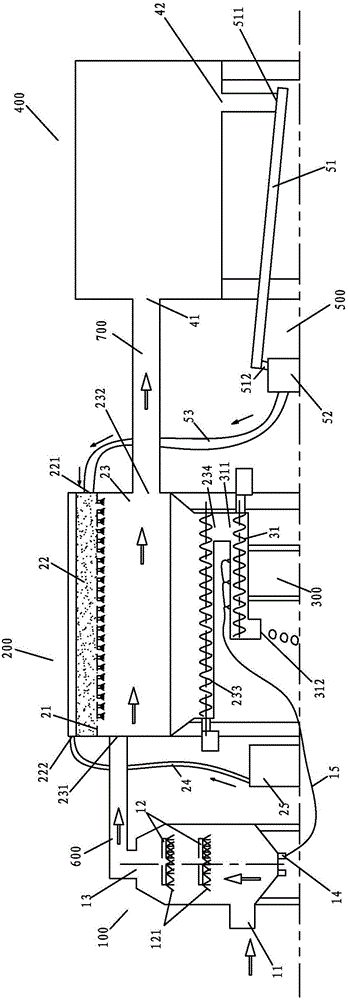

[0016] The tail gas and waste powder comprehensive treatment equipment of the complete set of asphalt regeneration and mixing equipment of the present invention, such as figure 1 As shown, it includes a water foam spraying chamber 100 , a recycled powder tail gas mixing chamber 200 , a waste powder humidification treatment device 300 , a bag filter 400 and a recycled powder conveying device 500 .

[0017] One side of the lower part of the water foam spray chamber 100 is provided with an air inlet 11 as an exhaust gas input port, and the middle position of the water foam spray chamber 100 in the height direction is provided with a plurality of spray pipes 12 distributed in concentric circles, and each spray pipe 12 is evenly distributed. Water atomization sprinkler heads 121 are distributed, and each spray pipe 12 is respectively connected to a water source, and each spray pipe 12 is provided with a water outlet communicating with the corresponding water atomization sprinkler he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com