Aluminum alloy forging die with fluid channels and aluminum alloy forging technique

A fluid channel, aluminum alloy technology, used in manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc., can solve the problems of long process, low efficiency, inability to control aluminum alloy deformation and accuracy problems , to solve the effect of long process, good heat dissipation capacity and poor plasticity at room temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

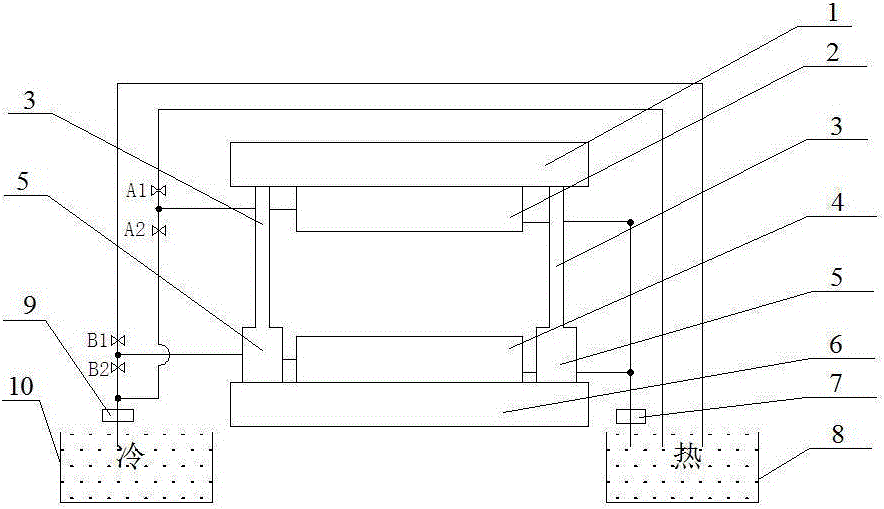

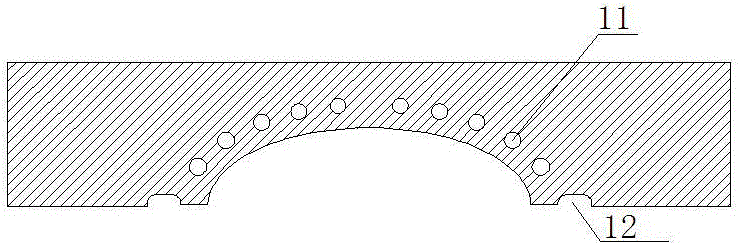

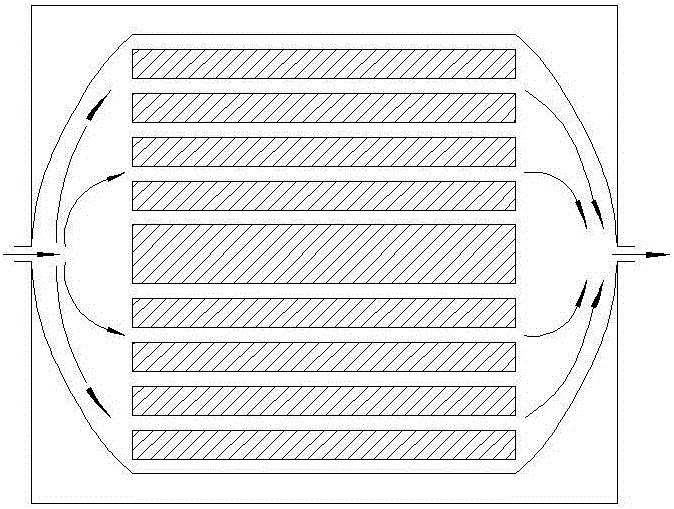

[0030] Such as figure 1 Shown, a kind of aluminum alloy forging mold with fluid channel comprises upper mold 2 and lower mold 4 (upper mold 2 and lower mold 4 are respectively fixed on upper mold base 1 and lower mold base 6, upper mold 2 and lower mold The whole of 4 is rectangular, the four sides of the upper mold 2 and the lower mold 4 are provided with countersunk screws for fixing on the mold base, and the four corners of the upper mold base 1 are respectively matched with four guide posts 3 and guide sleeves 5 , the lower mold 4 is fixed on the lower mold base 6 and does not move, and the upper mold 2 moves up and down along the guide column 3 under the drive of the upper mold base 1), and the upper mold 2 can move and apply pressure to the lower mold 4 (the lower pressure of the upper mold 2 Provided by the press), when the upper mold 2 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com