A cutting tool for machining rov propeller profile gear

A propeller and gear technology, which is applied in the direction of gear tooth manufacturing tools, manufacturing tools, components with teeth, etc., can solve problems such as gear tooth errors, achieve the effects of prolonging life, running smoothly, and improving bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

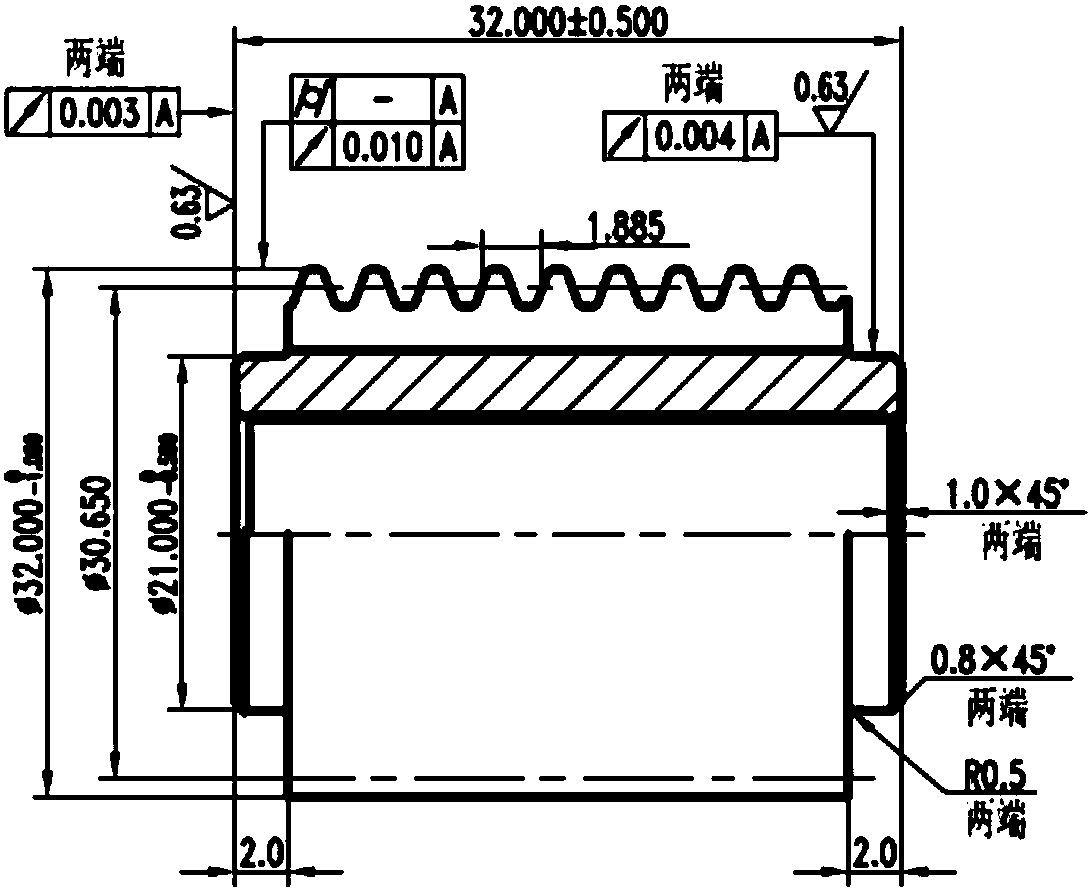

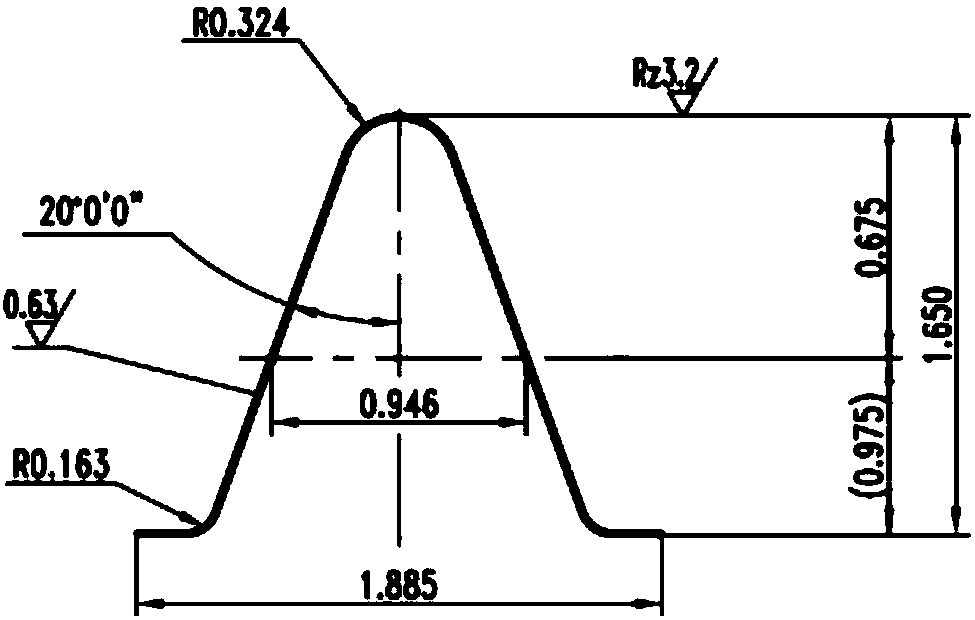

[0018] see Figure 1A ~ Figure 1C , a tool for processing ROV propeller profile gear provided by an embodiment of the present invention includes a tool holder and a hob disposed on the tool holder, the hob includes a plurality of hobbing teeth arranged in a continuous linear manner, any The tooth height of one of the hobbing teeth is 1.65cm, wherein, the tooth root height is 0.975cm, and the addendum height is 0.675cm; The radius of the root circle is 0.163cm (see Figure 1C ), the lead angle of the tooth thread is 1°7′18″, and the direction of rotation is right-handed (see Figure 1B ); the pitch between two adjacent hobbing teeth is 1.885cm (see Figure 1A );

[0019] The modulus of the hob is 0.6, the number of grooves is 12, and the pressure angle is 20° (see Table 1, which is a list of parameters of the process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com