Tool for machining modified gear of ROV propeller

A technology of propellers and gears, which is applied in the direction of gear tooth manufacturing tools, manufacturing tools, and components with teeth, etc., which can solve problems such as gear tooth errors, achieve the effects of prolonging life, uniform load distribution of tooth width, and improving bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be further described in detail below through the accompanying drawings and embodiments.

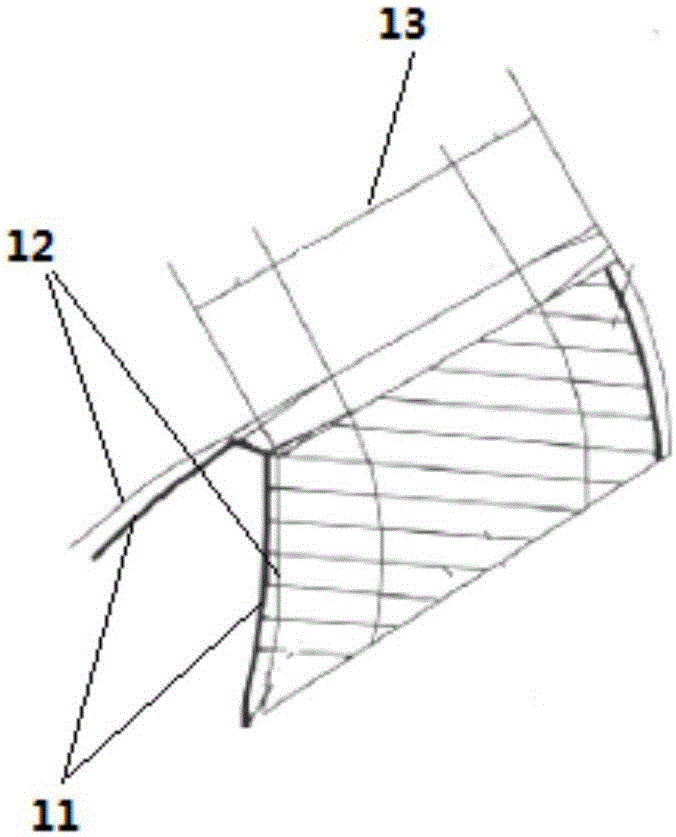

[0016] see figure 1 , an embodiment of the present invention provides a tool for processing ROV propeller trim gear, including a tool holder and a hob arranged on the tool holder, the hob comprises a plurality of continuous linearly arranged hobbing gears, any The tooth height of the hobbing gear is 1.65cm, wherein the tooth root height is 0.975cm, and the tooth tip height is 0.675cm; The radius of the root circle is 0.163cm, the rise angle of the tooth thread is 1°7′18″, and the rotation direction is right-handed; the pitch of two adjacent hobbing teeth is 1.885cm;

[0017] The modulus of the hob is 0.6, the number of grooves is 12, and the pressure angle is 20°; the helix angle of the blade groove is 0°, and the direction of rotation is a straight groove; the radius of the base circle is 0.823cm, and the rise angle of the bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com