Electrode wire disc damper of electric spark fast wire moving linear cutting machine tool

A cutting machine, EDM technology, applied in electrode manufacturing, electric processing equipment, metal processing equipment, etc., can solve the problems of high tension of the electrode wire, inability to rotate at will, loose electrode wire, etc., to improve the efficiency of plate changing, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

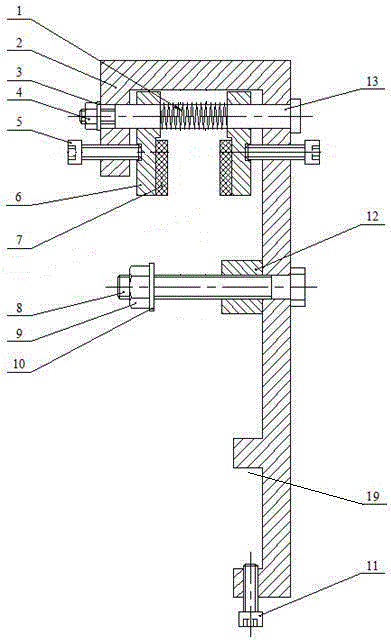

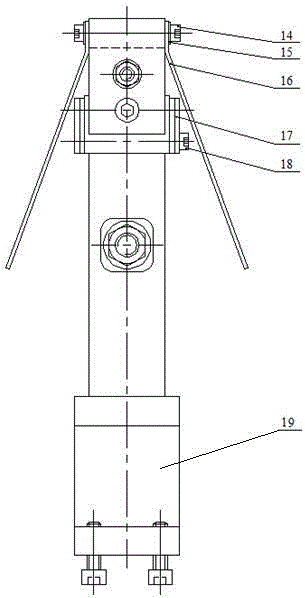

[0029] combine figure 1 and figure 2As shown, the present invention includes a support 2, the bottom of one side of the support 2 is provided with a clamping groove 19 for fixing the machine tool, one side of the upper part of the support 2 is provided with a wire disc support rod 8, and the electrode wire disc sleeve Placed on the wire reel support rod 8, the support 2 is provided with a damping sheet above the wire reel support rod 8, and the damping sheet is provided with two, respectively located on both sides of the wire electrode wire reel, and connected with the wire electrode The end faces of both sides of the wire reel are attached; the top of the bracket 2 is bent toward the side of the wire reel support rod 8 to form a "C"-shaped groove, the notch of the "C"-shaped groove is downward, and the damping sheet is set On the groove wall in the "C"-shaped groove; the damping sheet includes a bottom plate 6 connected with the groove wall in the "C"-shaped groove, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com