A hp-x3 automatic lens chip mounter

A HP-X3, fully automatic technology, applied to mechanical equipment, devices for coating liquid on the surface, connecting components, etc., can solve the problems of inability to automatically change discs, inaccurate recognition accuracy, and low degree of automation, and achieve improved The effect of dispensing efficiency, high precision and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

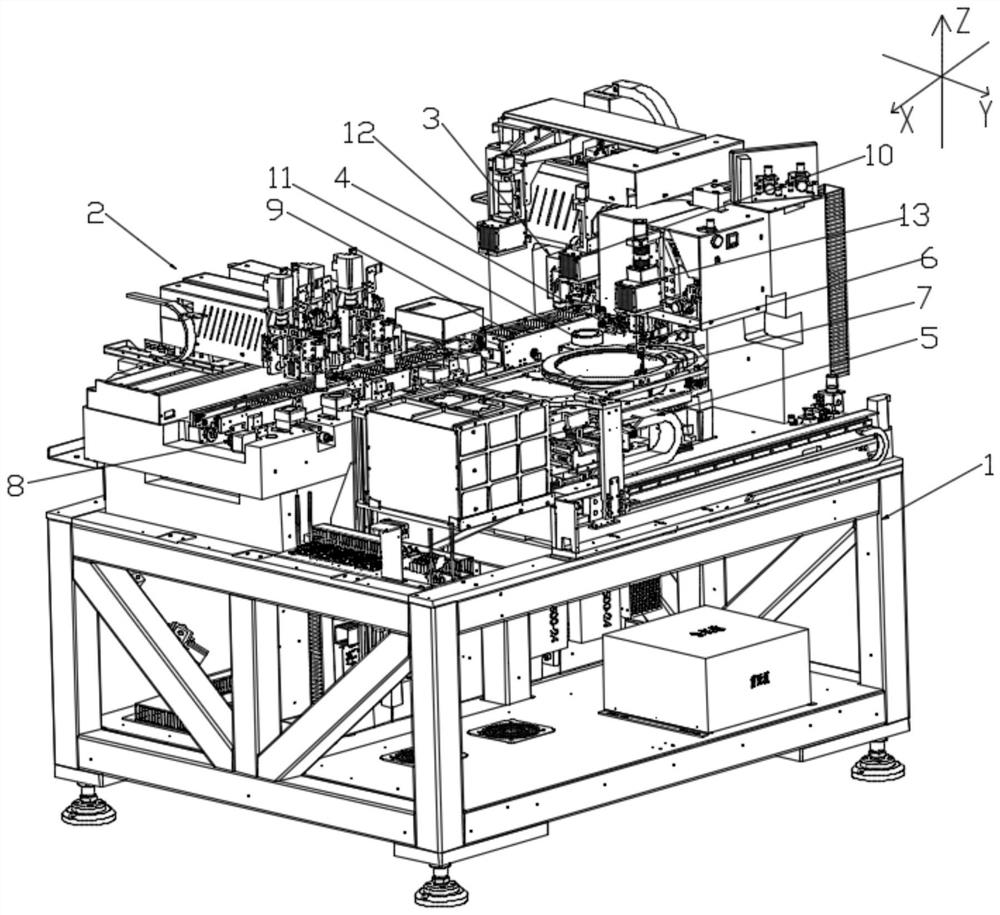

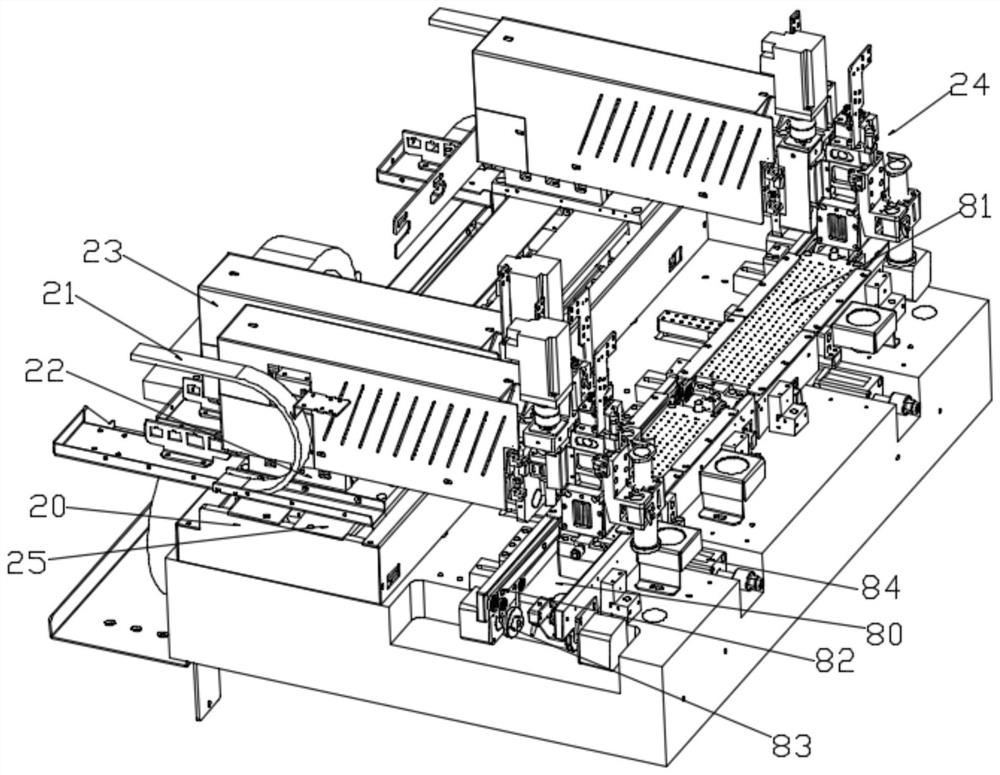

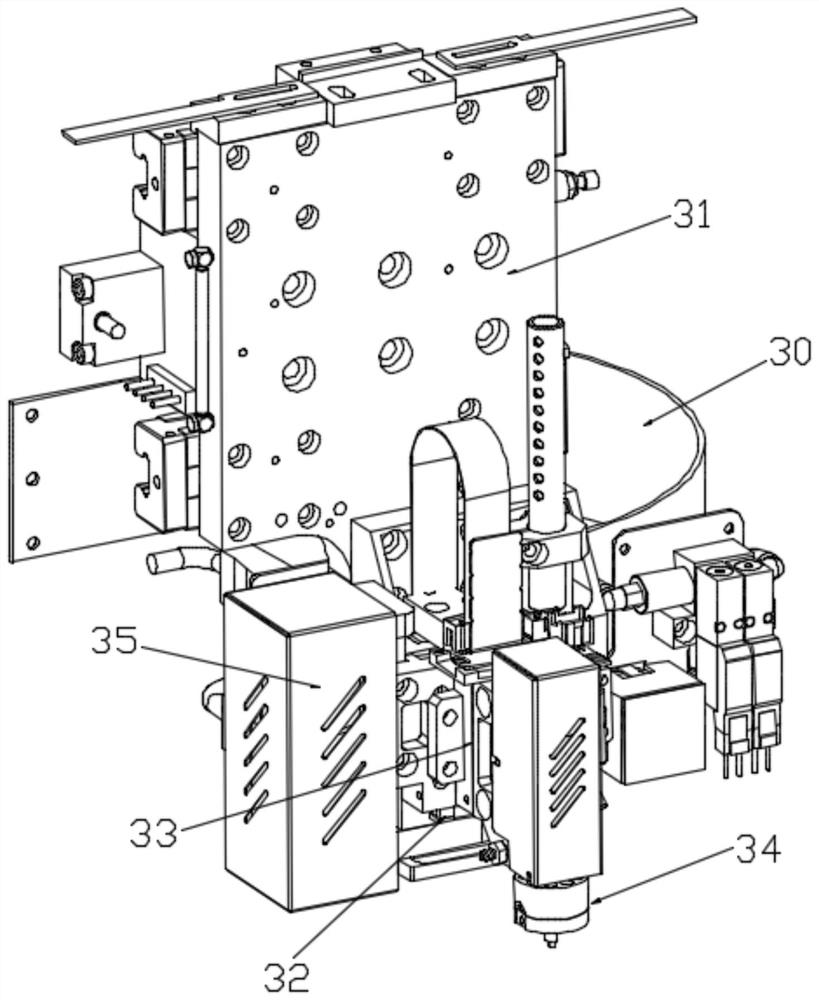

[0033] Please refer to Figure 1 - Figure 11 The present invention provides an HP-X3 automatic lens chip mount machine, including: a rack 1, a dispensing mechanism 2, a patch mechanism 3, a luminance correction component 4, an automatic changing plate The mechanism 5 is disposed on the swing arm assembly 6 on the upper side of the automatic changing mechanism 5; one side of the dispensing mechanism 2 is provided with a dot gel drive assembly 8, and the bottom pin assembly is provided at the bottom of the automatic changing mechanism 5. 7. The first position detecting device 10, the second position detecting device 11, respectively, and the second position detecting device 11 are provided, respectively, and the dot gelatin mechanism 2 is used for the entrainment of the fixtures. Glue; the point glue drive assembly 8 is used to deliver the trigger carrier pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com