A disc pushing device for an automatic disc-changing wire take-up machine

A wire take-up machine and automatic technology, which is applied in the direction of transportation and packaging, thin material handling, and delivery of filamentous materials, etc., can solve the problems of limited installation position of the cylinder, high manpower time consumption, and high labor intensity, etc., to achieve improvement Efficiency of disk changing, saving of installation space and improvement of wire take-up efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings, but the required protection scope is not limited to the description;

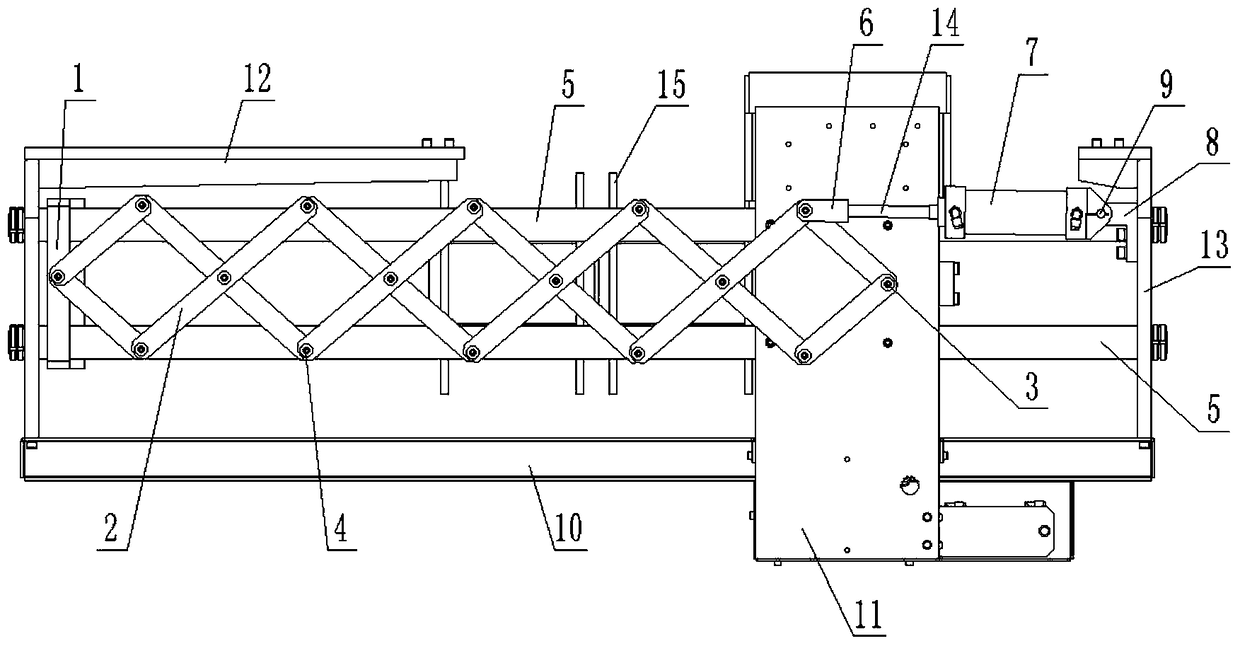

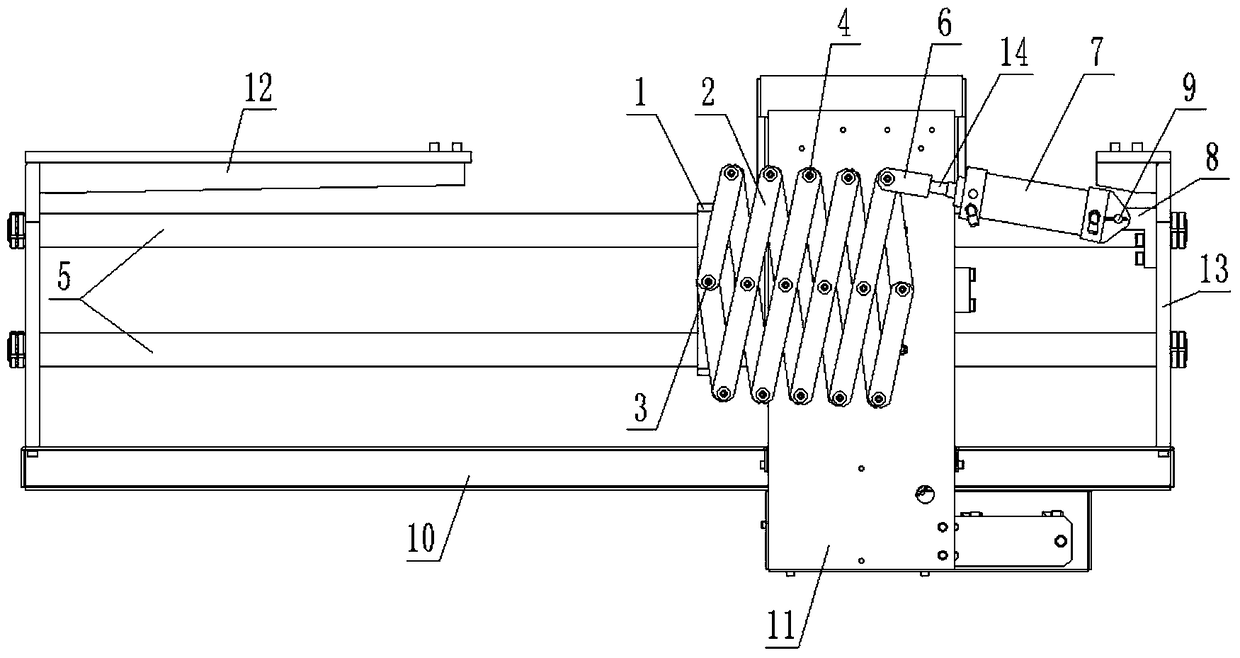

[0016] Such as Figure 1-2 As shown, the disc pushing device for automatic disc-changing and take-up machines provided by the present invention includes a mounting base 10, a mounting plate 11 is fixedly connected to the mounting base 10, and a disc feeding mechanism is installed on the mounting plate 11, which can automatically realize To unload the I-shaped wheel 15 with the full line, the two ends of the mounting seat 10 are fixed with side plates 13 perpendicular to it, and two parallel and spaced sliders are fixed between the two side plates 13. The rod 5 is fixedly connected with a fixed seat 8 on the inside of a side plate 13 near the mounting plate 11, and the end of the fixed seat 8 is hinged with a cylinder 7 through a hinged rod 9. The cylinder 7 can rotate freely on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com