Welding fixture for once clamping multiple short ring parts

A technology for welding fixtures and parts, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as large workload and low production efficiency, and achieve low manufacturing costs, cost savings, and multiple pumping. Effect of vacuum phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

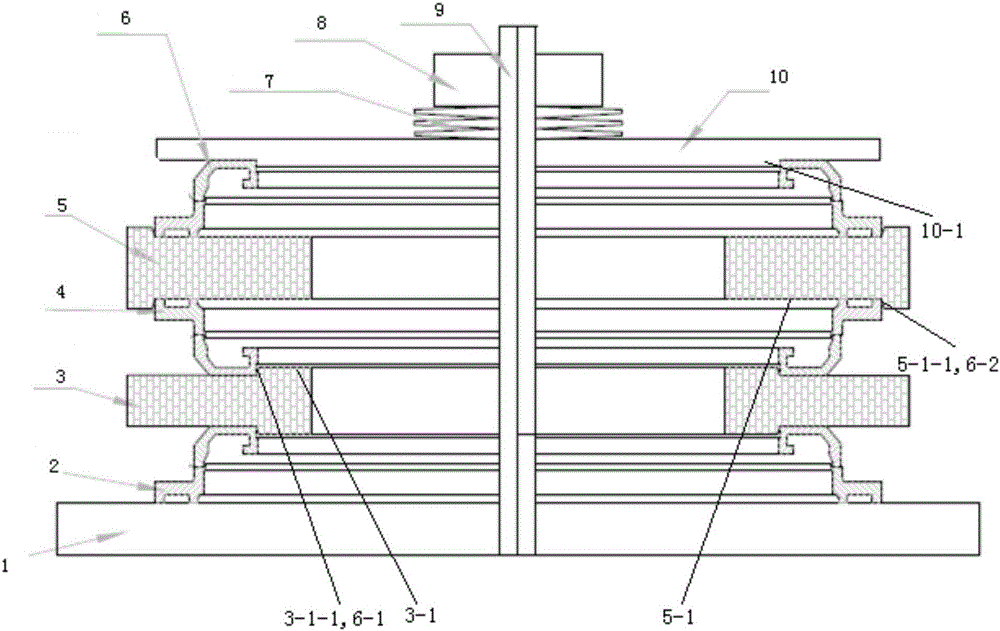

[0040] Such as figure 1 As shown, the welding fixture of the present invention clamps multiple short ring parts at one time clamps 3 parts, such as the first part 2, the second part 4 and the third part 6, in the clamping parts ( 2, 4 and 6), the large diameter end of the first part 2 is placed on the upper surface of the chassis 1, and then the first transition ring 3 is placed on the end face of the small diameter end of the first part 2, so that the first The boss on the lower surface of the transition ring 3 extends into the small-diameter end of the first part 2 and the inner edge surface of the small-diameter end of the first part 2 is in contact with the outer sidewall of the boss on the lower surface of the first transition ring 3. The first transition ring 3 The lower surface on the lower surface is in close contact with the end surface of the small-diameter end of the first part 2; The boss extends into the small-diameter end of the second part 4 and the inner edge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com