Tool-blocking tool-dropping fault early-warning device for circular disc type manipulator tool magazine

A fault early warning, disc-type technology, applied to positioning devices, metal processing machinery parts, manufacturing tools, etc., can solve problems such as unstable operation, negative impact on production efficiency, production suspension, etc., and achieve the effect of reducing labor intensity

Active Publication Date: 2017-02-15

吉林大学重庆研究院

View PDF8 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The disc-type manipulator tool magazine is a typical tool magazine system, which is mainly used in machining centers and other equipment for storing and changing tools, which improves the automation of CNC machine tools and plays an important role in production. Once the disc If the mechanical arm tool magazine fails, it will have a greater negative impact on production efficiency

[0003] The statistical results in recent years show that as the main key functional components of CNC machine tools, the overall output of domestic disc manipulator tool magazines has continued to increase for many years, but it is prone to failure and unstable operation. The main failure modes include tool jamming and dropout. Once the knife or knife jamming fault occurs, it will lead to the failure of the tool change in the disc-type manipulator tool magazine, resulting in suspension of production and affecting production efficiency. In severe cases, the load on the motor of the manipulator will increase and the motor will burn out; As a result, the tool change of the disc-type manipulator tool magazine is unsuccessful, resulting in production suspension, affecting production efficiency, and the falling tool handle will fall, smashing the machine tool and the workpiece, and may even accidentally injure the worker. The consequences are unimaginable.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment approach

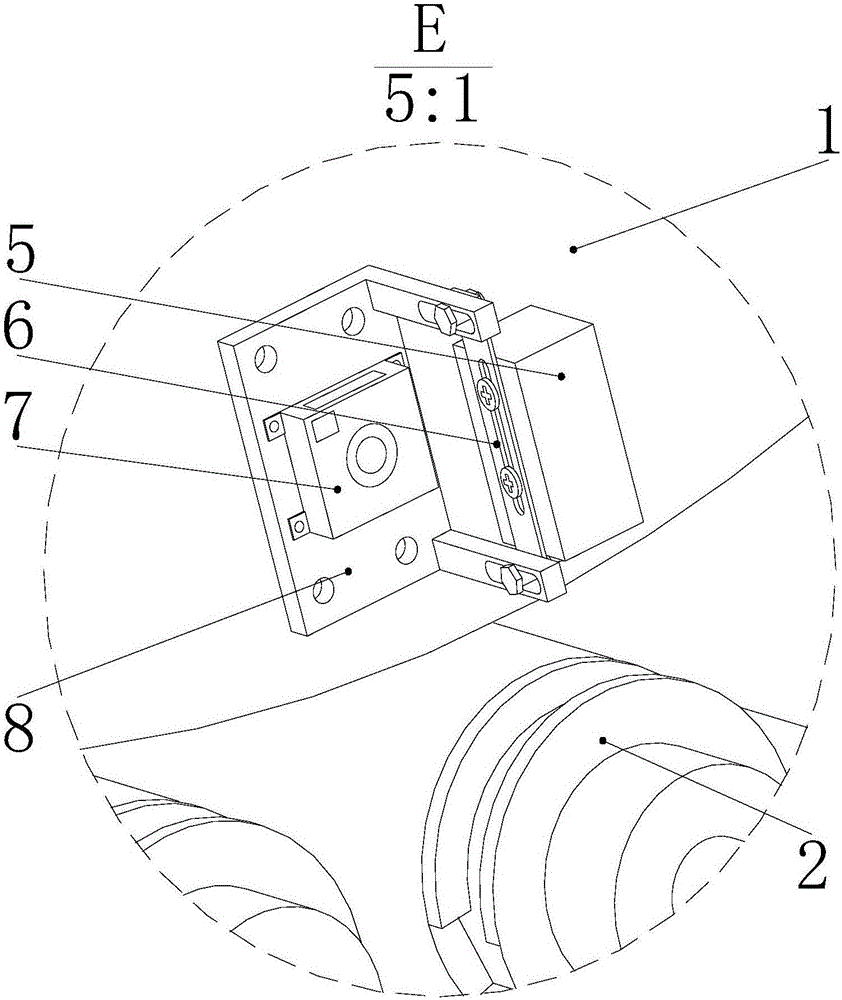

[0069] 1. The model of the selected color mark sensor can be selected according to the difference of the disc manipulator tool magazine;

[0070] 2. Add some protection devices such as overcurrent and overload relays to the circuit of the alarm;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

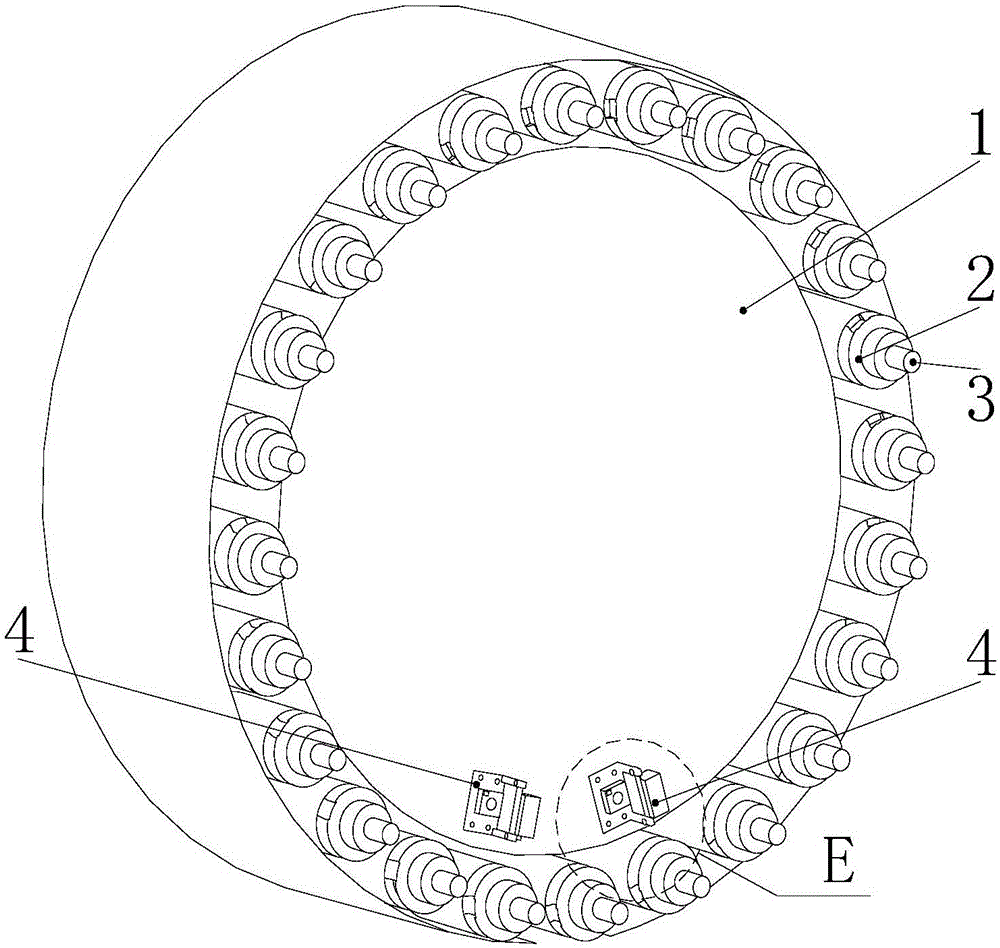

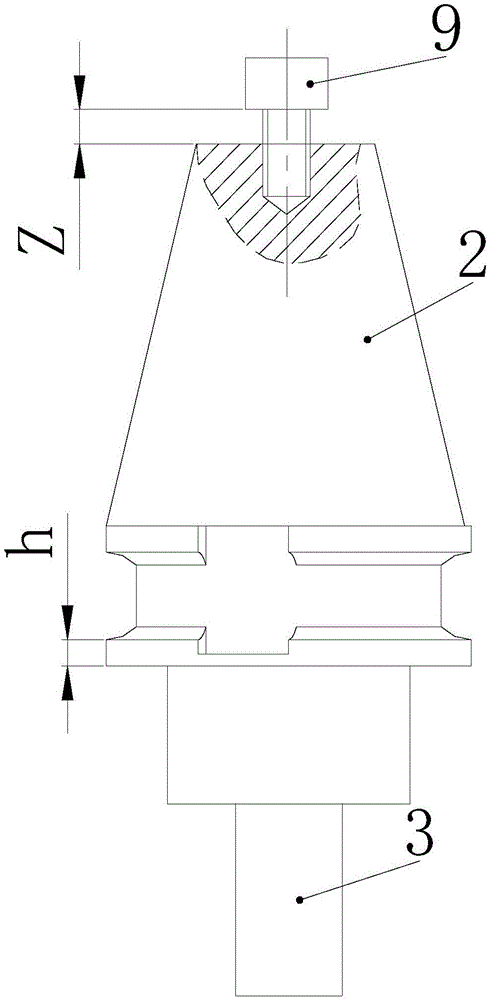

The invention discloses a tool-blocking tool-dropping fault early-warning device for a circular disc type manipulator tool magazine, and aims to carry out early-warning for tool-dropping and tool-blocking faults of an existing numerical-control machine circular disc type manipulator tool magazine. The tool-blocking tool-dropping fault early-warning device comprises two early-warning units, wherein each early-warning unit consists of a color mark sensor, a beam, an alarm and a bracket. The tool-blocking tool-dropping fault early-warning device for the circular disc type manipulator tool magazine disclosed by the invention can comprehensively detect that screw joint between a shank and a blind rivet loosens, can detect screw joint looseness with different degrees between the shank and the blind rivet according to the needs, is suitable for circular disc type manipulator tool magazines of different models, shows flexibility and universality, can automatically operate for a long time under an unmanned monitoring state, can reduce labor intensity, exposes and arouses product faults, provides practical essential data for reliability evaluation of the circular disc type manipulator tool magazine, and also can be used for screening chain-plate circular disc type manipulator tool magazines.

Description

technical field [0001] The invention relates to a device for early warning of faults applied to a disc-type manipulator tool magazine on a numerically controlled machine tool. Early warning device. Background technique [0002] CNC machine tools are the basis for improving the national manufacturing level and equipment level, and are an important symbol to measure a country's industrial development level and comprehensive national strength. As a device commonly equipped with CNC machine tools, the tool magazine system is a device that provides tool storage and tool change requirements in the automated machining process. It consists of a tool change mechanism and a tool magazine that can store multiple tools, changing the traditional The human-centered production method can complete various processing requirements through program control, such as milling, drilling, boring, tapping, etc., which greatly shortens the processing time and reduces production costs. The disc-type ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23Q3/157B23Q11/00

CPCB23Q3/157B23Q11/0078

Inventor 陈传海杨兆军田海龙姜怀胜李全普陈菲李国发许彬彬朱晓翠杨丁宇

Owner 吉林大学重庆研究院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com