A fast-reversing feeding mechanism

A technology of reversing mechanism and feeding mechanism, which is applied in metal processing and other directions, can solve the problems of overall complexity, large space occupation, and low feeding efficiency, and achieve the effects of reducing system quality, saving floor space, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments. It should be understood that these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention. In addition, it should be understood that after reading the content taught by the present invention, those skilled in the art may make various changes or modifications to the present invention, and these equivalent forms also fall within the scope defined in the present application.

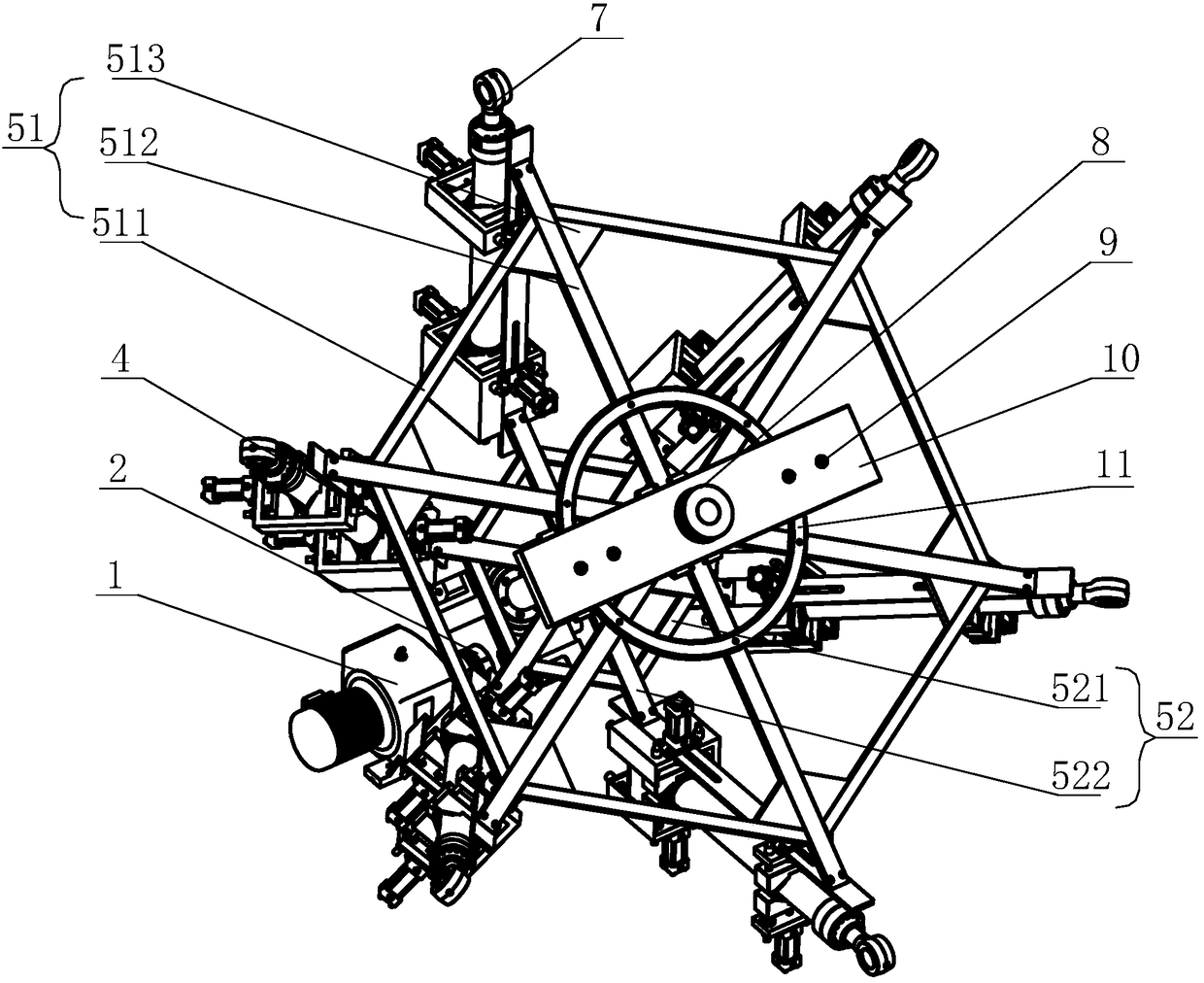

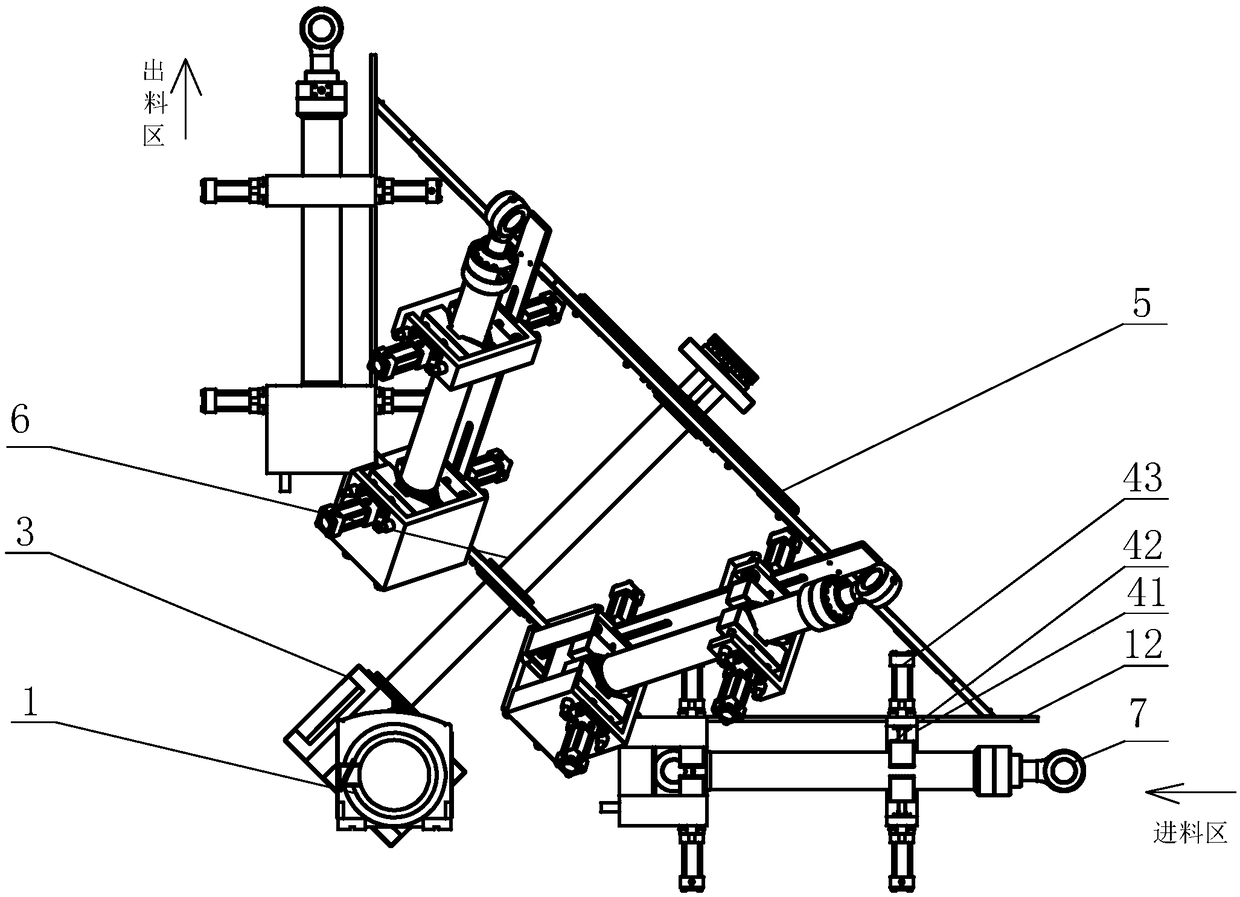

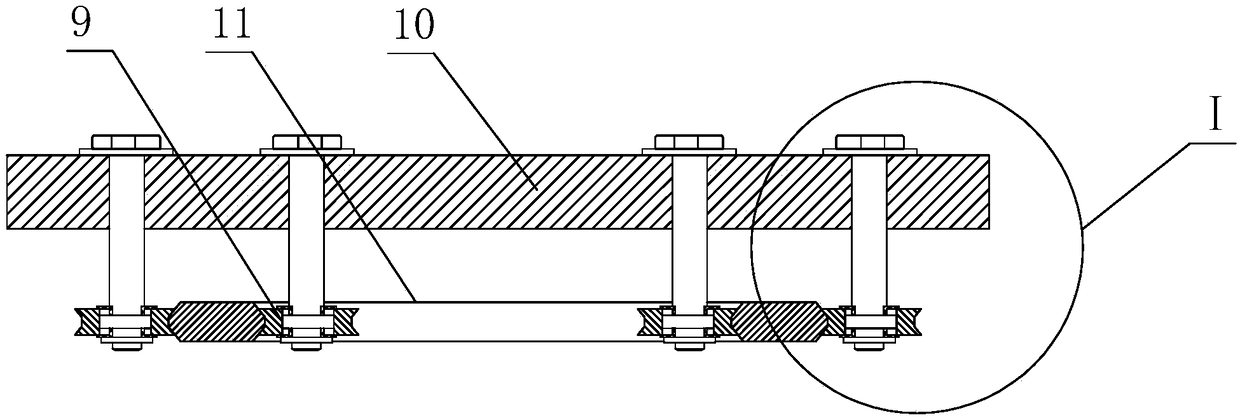

[0032] as attached Figure 1~4 As shown, a fast reversible feeding mechanism includes a geared motor 1 and a multi-station indexer 3. The multi-station indexer 3 is connected to a rotating bracket 5 arranged obliquely. The self-adaptive fixture 4 used to clamp the material 7, the multi-station indexer 3 drives the rotating bracket under the drive of the gear motor 1 to realize the intermittent movement of multiple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com