A protective device for manual polishing of light guide plates

A protection device, light guide plate technology, applied in grinding/polishing safety devices, surface-polished machine tools, grinding/polishing equipment, etc. Edge or slump, simple structure, easy to fix and hold the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

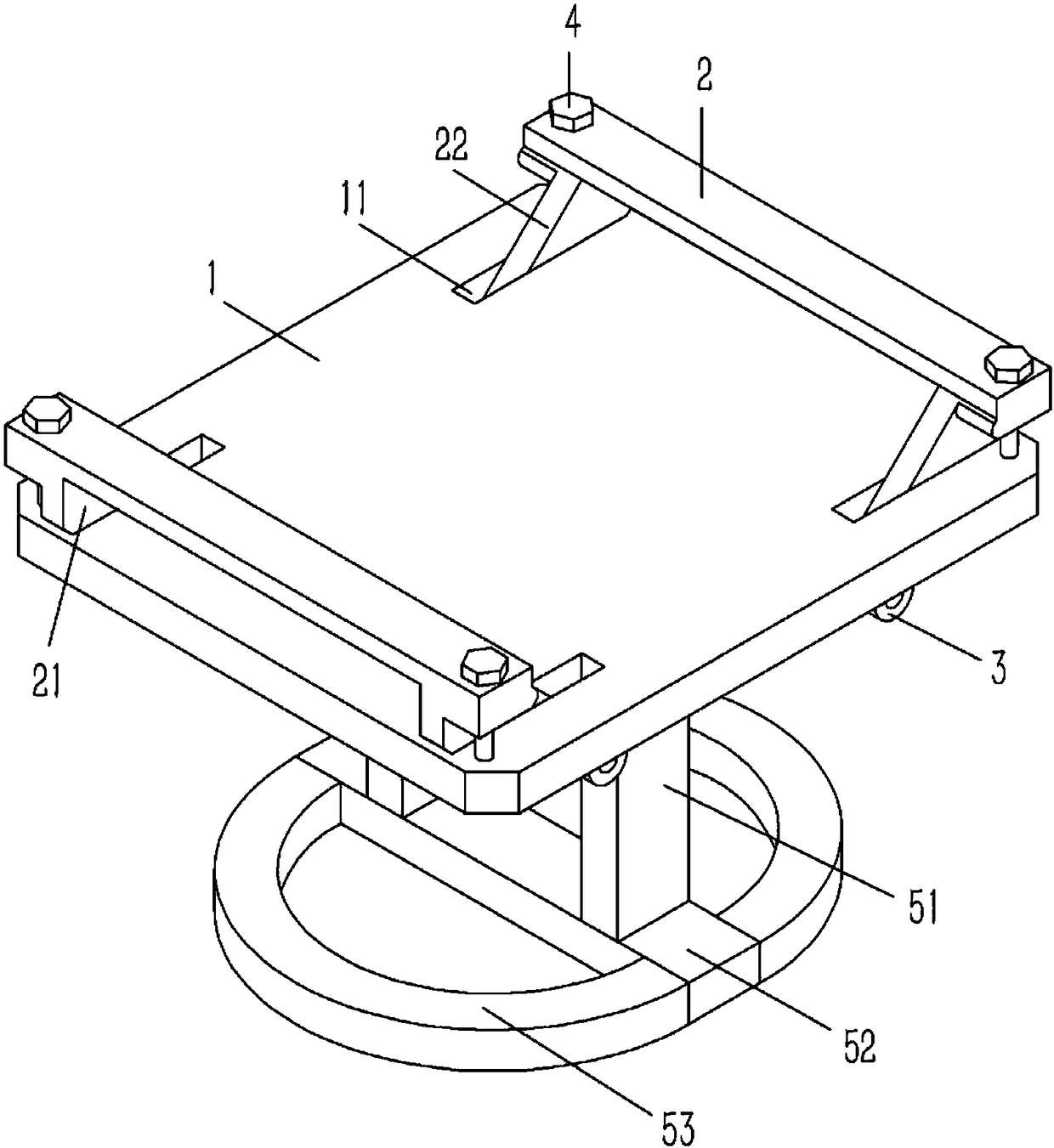

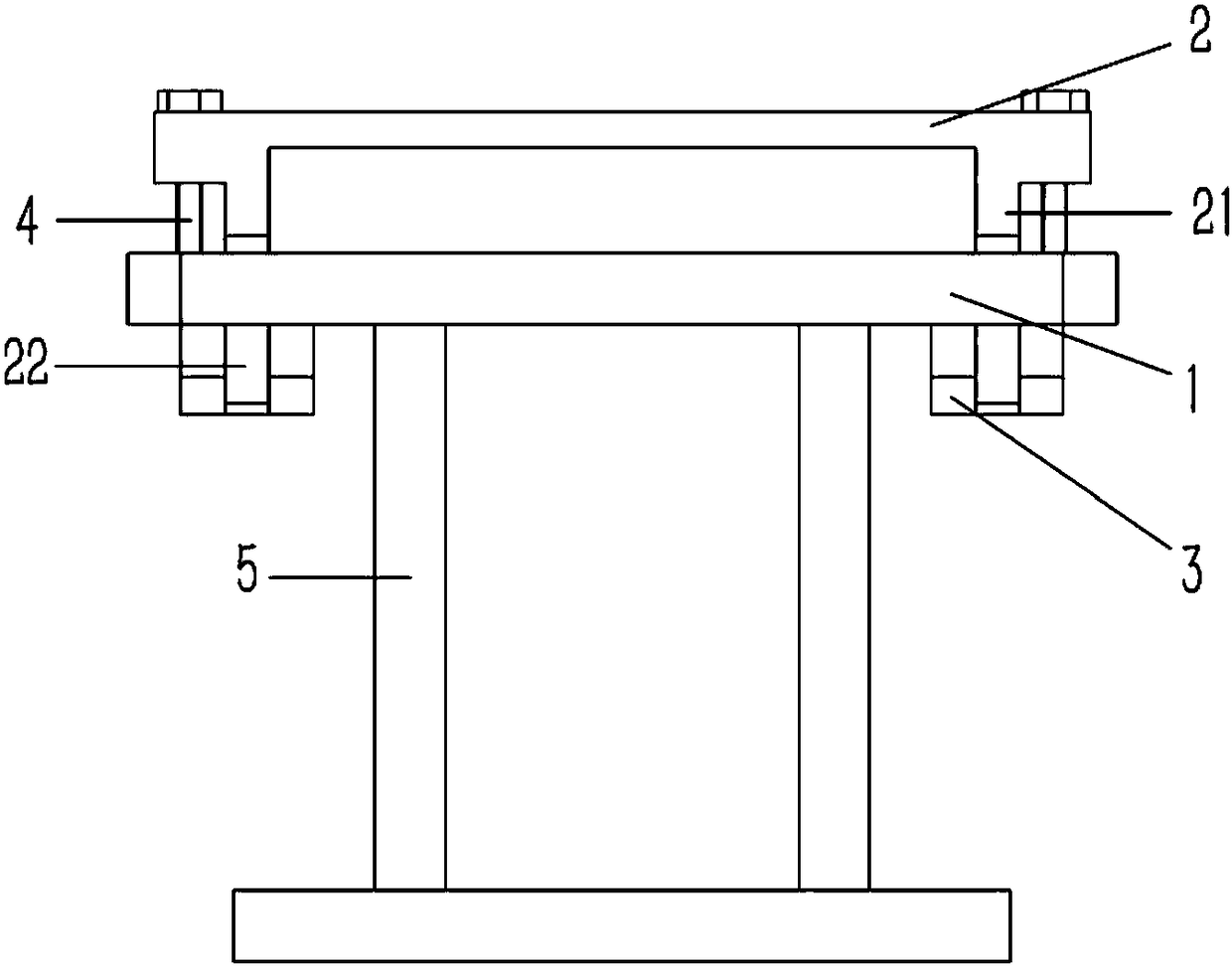

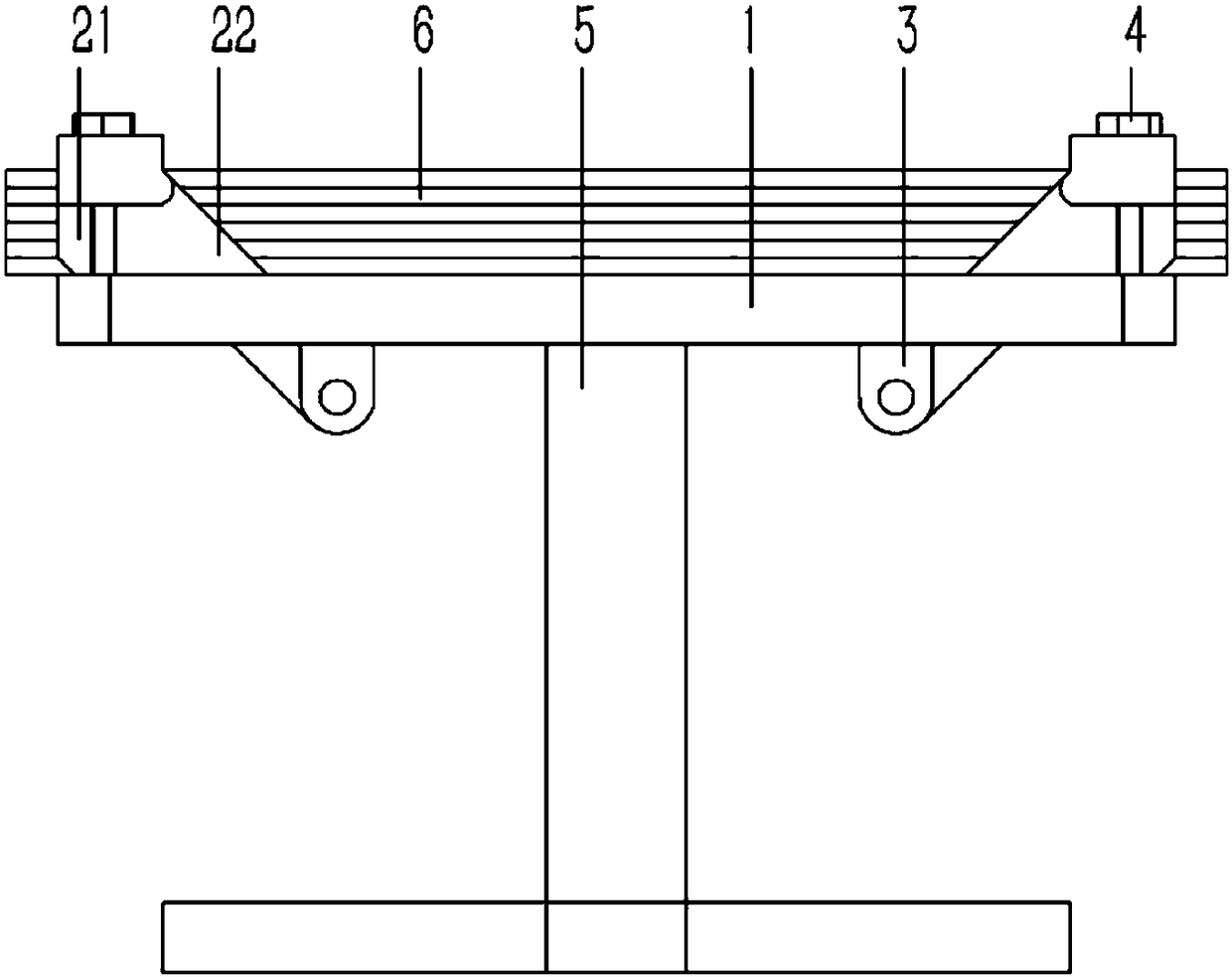

[0015] Example: see Figures 1 to 3 As shown, a protection device applied to manual polishing of light guide plates, including a rectangular platform 1, organic feet 5 are fixed on the lower end surface of the platform 1, horizontal grooves 11 are formed at the four corners of the platform 1, and the upper sides of the platform 1 A longitudinal strip-shaped pressure plate 2 is formed, and the lower end surface of the strip-shaped pressure plate 2 near both ends is formed with a stopper 21, and an inclined connecting rod 22 is formed on the stopper 21, and the lower end of the connecting rod 22 passes through the channel 11 of the platform 1 And through the hinge shaft and the hinge seat 3 are hinged, the hinge seat 3 is fixed on the lower end surface of the platform 1; the two ends of the bar-shaped pressure plate 2 are inserted with vertical fastening bolts 4, and the fastening bolts 4 are screwed on the platform 1 superior.

[0016] The lower end surface of the stopper 21 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com