Universal manufacturing device for integrated circuits

A technology for manufacturing devices and integrated circuits, applied in the field of general-purpose manufacturing devices for integrated circuits, can solve the problems of increasing labor intensity of manual cleaning, reducing wafer processing efficiency, and wafer surface collision damage, saving labor intensity and having a wide range of applications. , the effect of increasing the usable area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

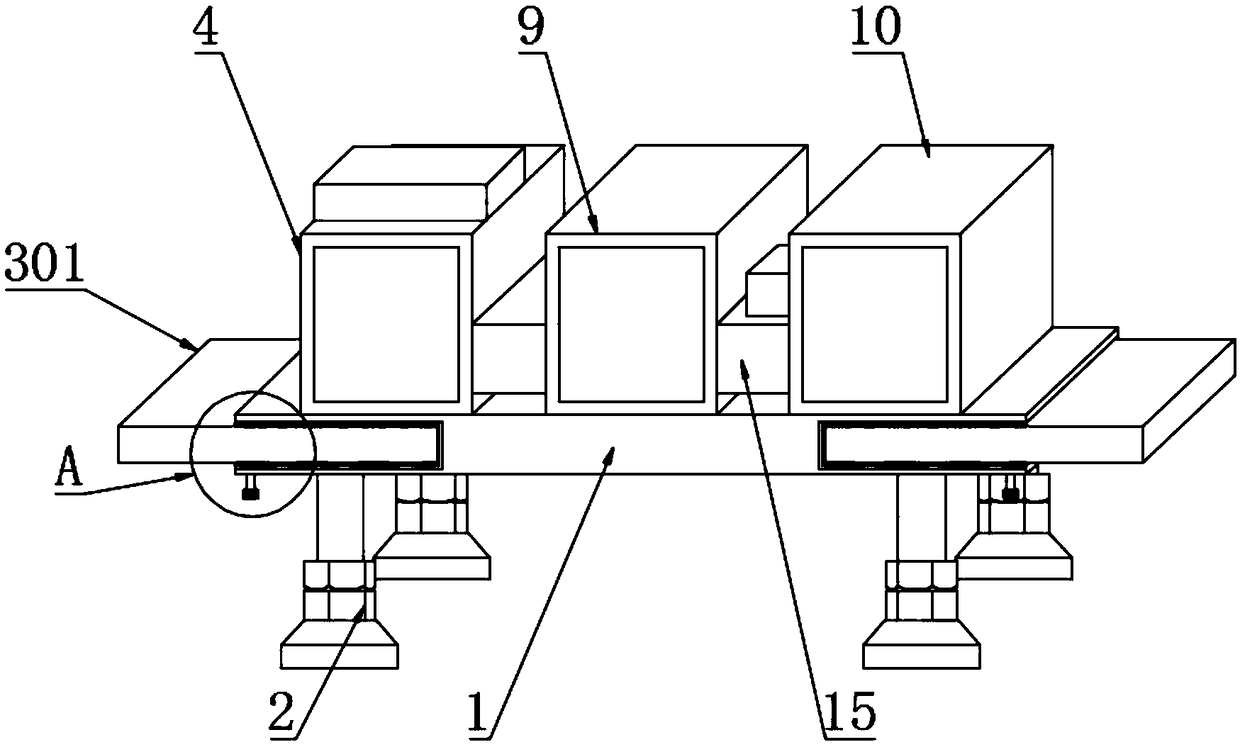

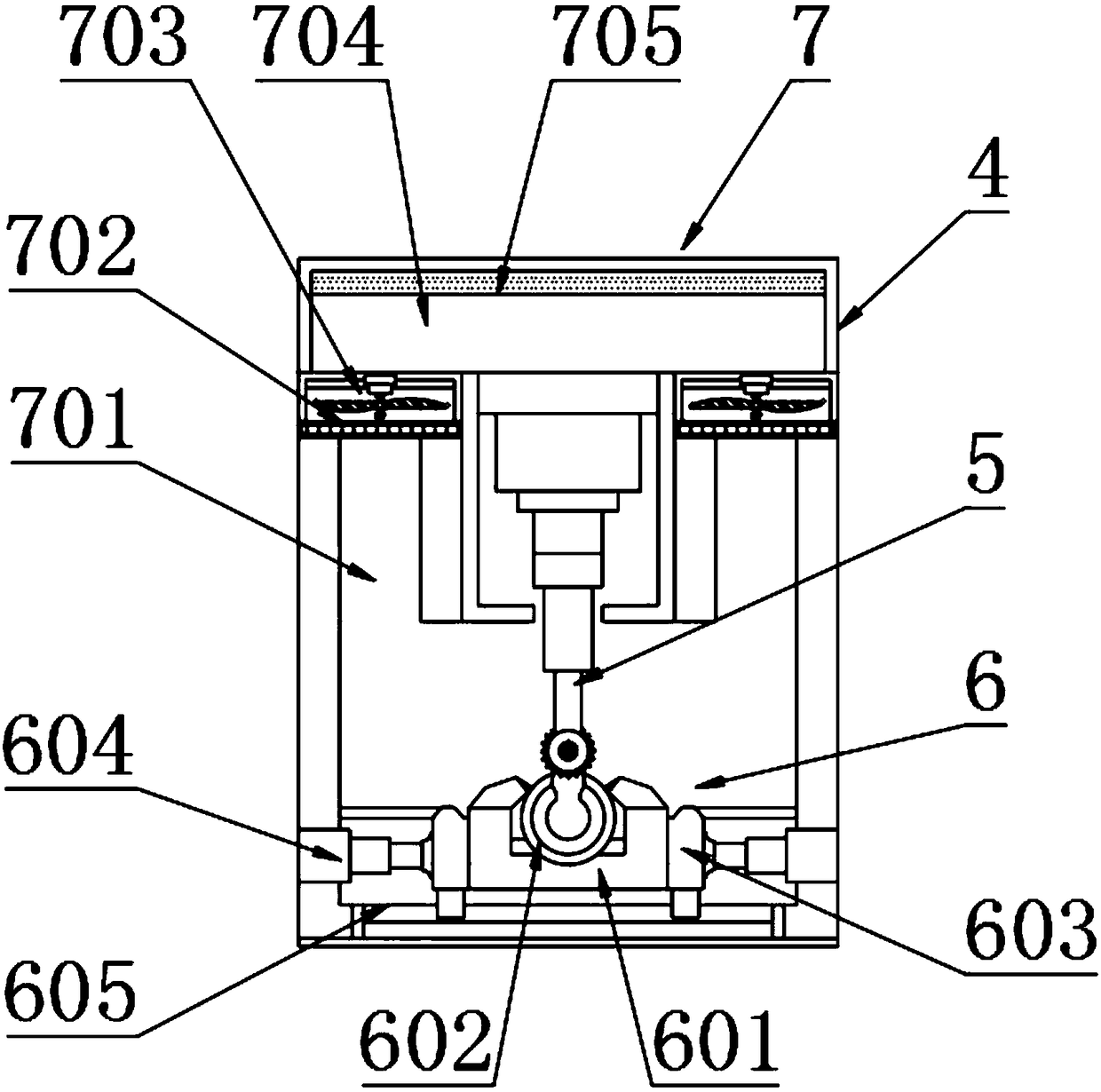

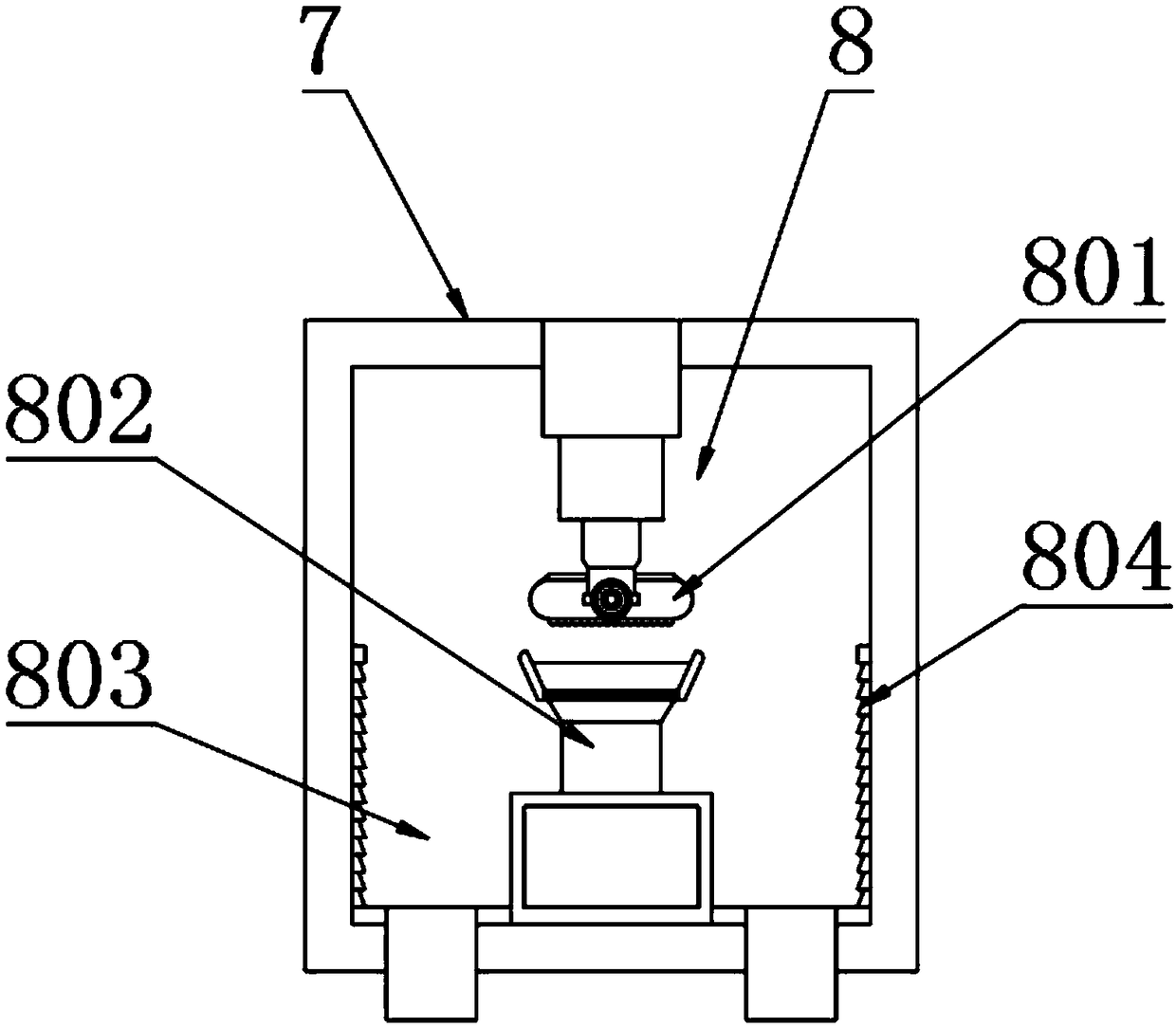

[0030] Example: such as Figure 1-6As shown, the present invention provides a technical solution, a general integrated circuit manufacturing device, including a manufacturing table 1, and an adjustable support 2 is fixedly supported by welding under the bottom of the manufacturing table 1, in order to facilitate the adjustment of the overall height of the manufacturing table 1 , and at the same time make the adjustable support 2 more stable when supporting the manufacturing table 1, the bottom of the adjustable support 2 is provided with an adjusting bolt, and the bottom of the adjustable support 2 is provided with anti-slip gaskets, and the two sides of the manufacturing table 1 Stretching components 3 are symmetrically installed on all parts. The stretching components 3 include a stretching table 301, a fitting chute 302, a movable roller 303 and a fastening knob 304. The inner side of the manufacturing table 1 is provided with a fitting chute 302. The middle part of the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com