Copper pipe clamping device

A clamping device, copper tube technology, applied in vices, manufacturing tools, etc., can solve the problems of copper tube surface deformation, time-consuming and laborious, and achieve the effect of enhancing friction, avoiding deformation, and avoiding rotation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

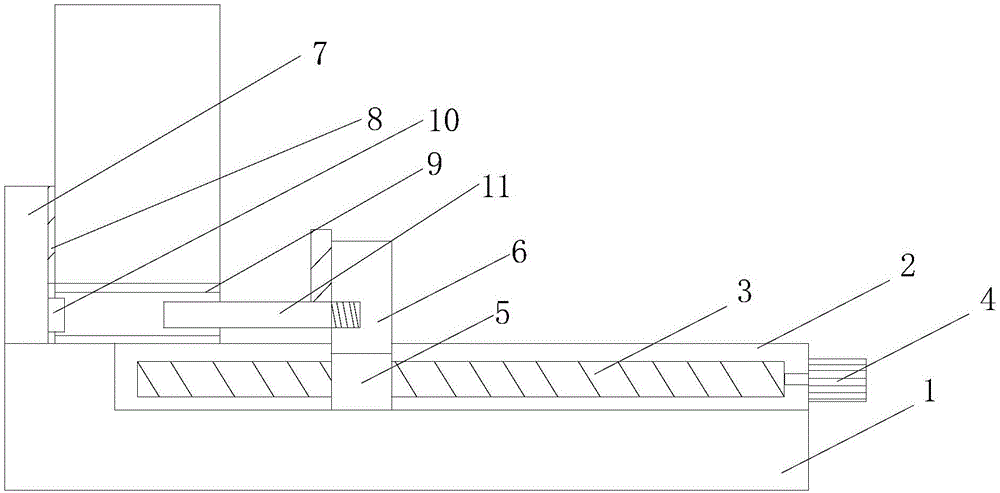

[0014] see figure 1 As shown, a copper tube clamping device is characterized in that it includes a base 1, and a bar-shaped groove 2 is provided on the top surface of the base; a ball screw 3 is arranged in the bar-shaped groove, and one end of the ball screw extends out of the base A motor 4 is connected to the outside; a first clamping block 6 is connected to the nut 5 set on the ball screw, and a second clamping block 7 is arranged on the top of the base away from the motor; the first and second clamping Friction pads 8 are provided on the inner side of the holding block; a hollow support block 9 is provided on the base between the second holding block and the slot, and a permanent support block is provided on the side of the second holding block close to the support block. Close switch 10; the bottom end of the first clamping block is detachably connected with a contact rod 11 used in conjunction with a normally closed switch. By setting the ball screw in the strip groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com