A kind of retrieving device and retrieving method

A technology of a reclaiming device and a lifting device, which is applied in the field of machinery, can solve the problems of product falling, small injection molding products, easy air leakage, etc., and achieves the effects of reducing the falling rate, simple structure and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

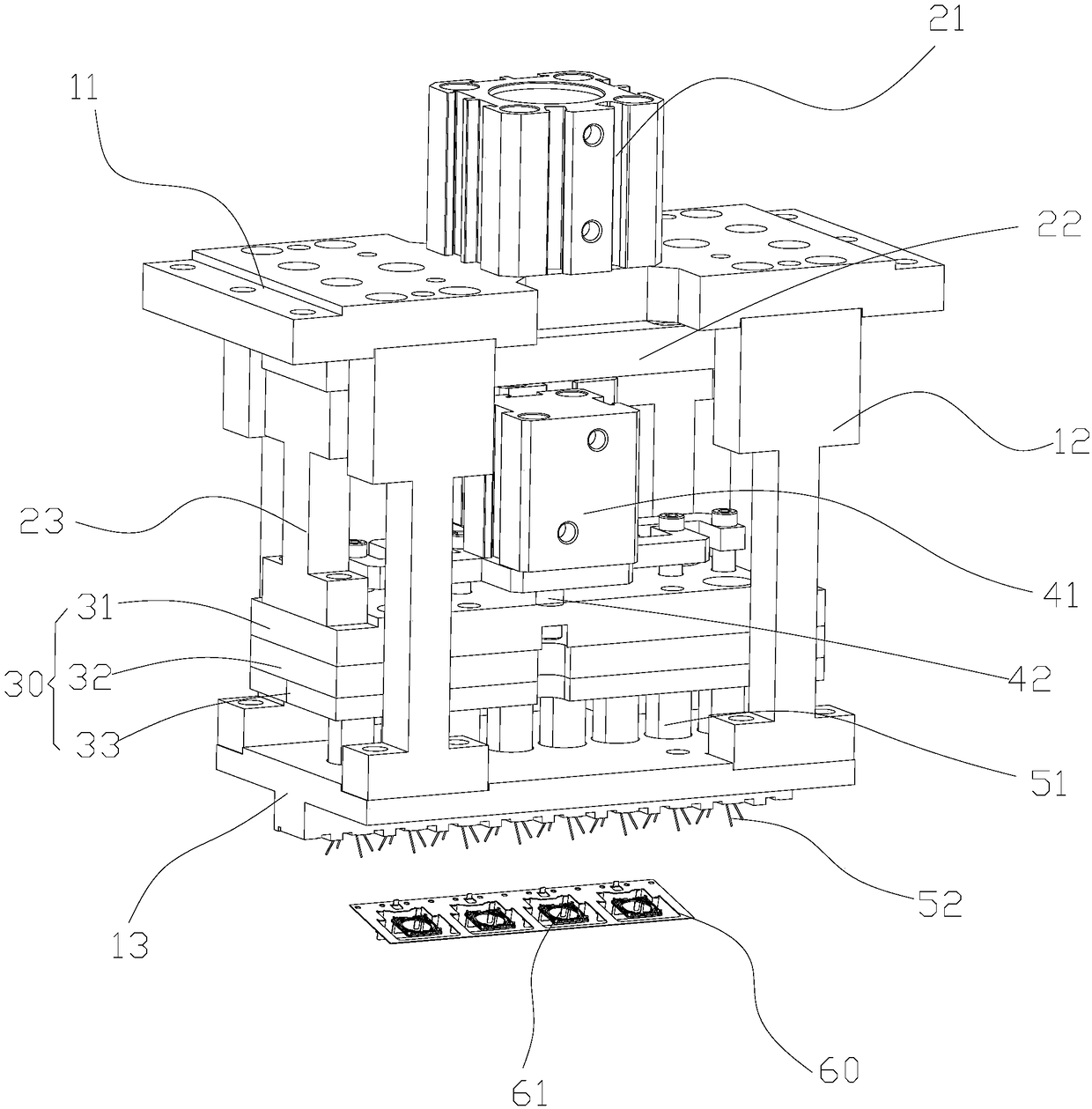

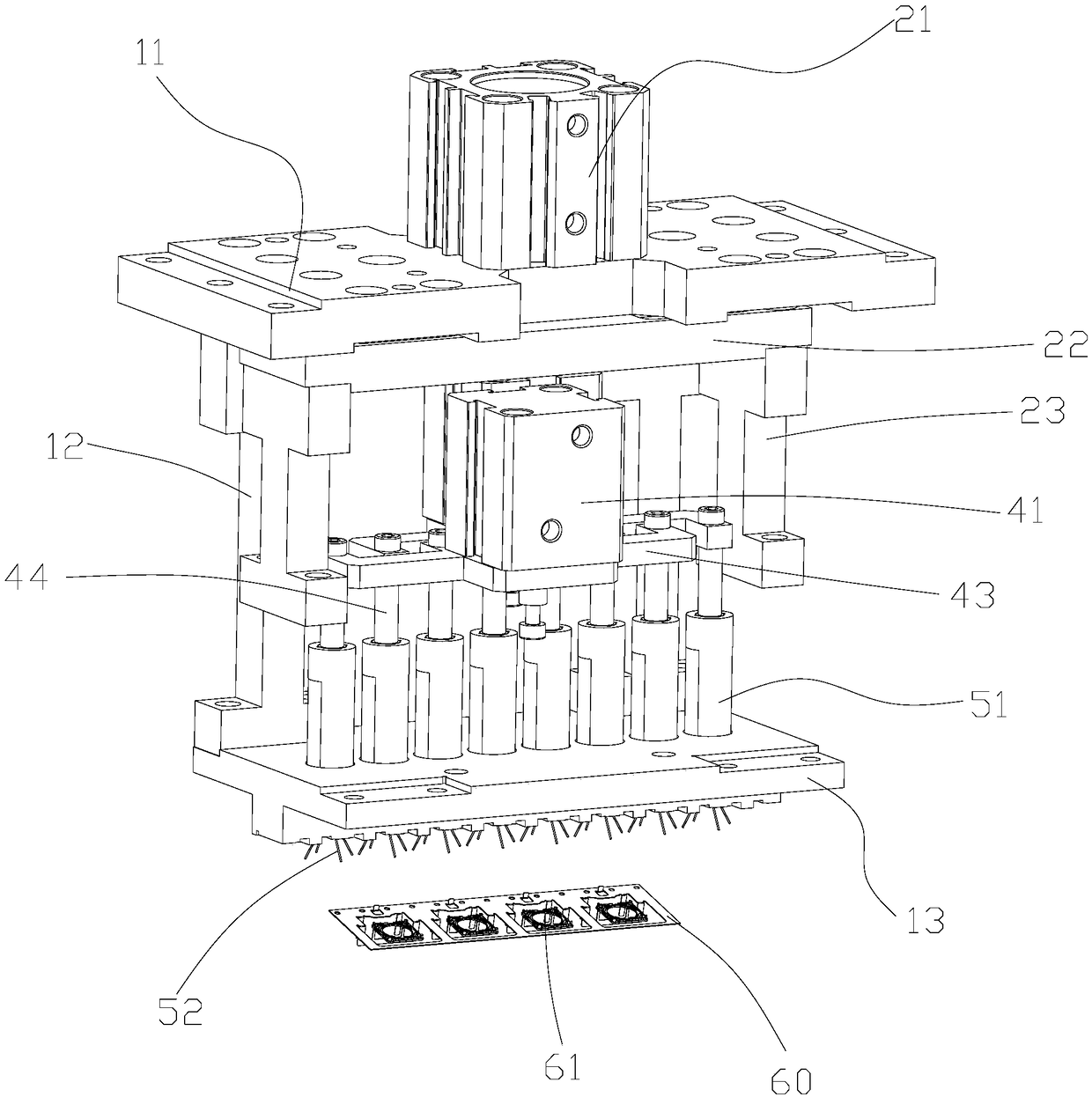

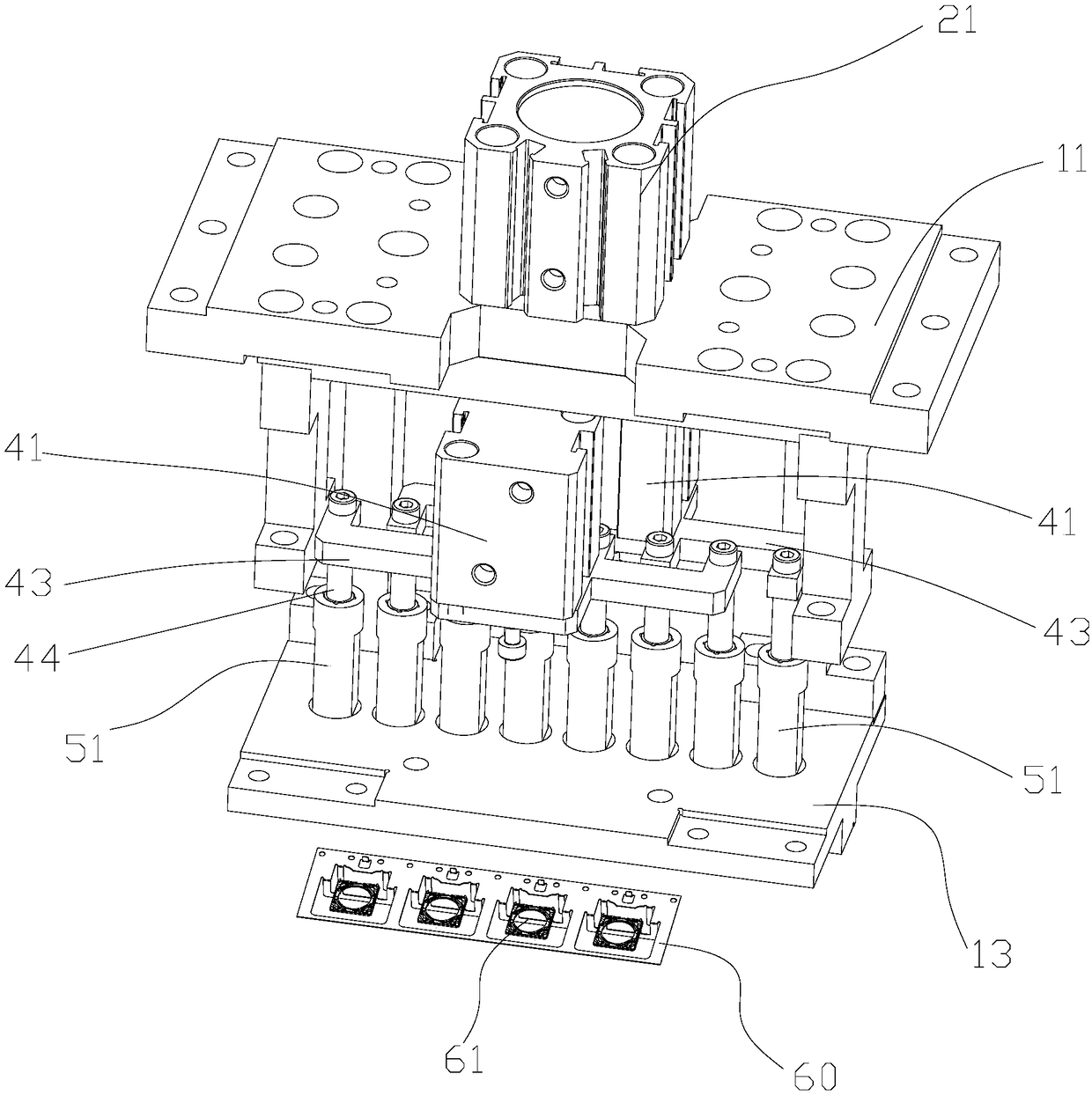

[0035] refer to Figure 1 to Figure 6 As shown, a kind of retrieving device provided in this embodiment includes: a body, a lifting mechanism and eight groups of retrieving components. Composed of four uprights 12, the retrieving assembly includes: a collision portion, a retrieving head 51 and a claw provided with four claws 52, the claws 52 are long rod-shaped elastic bodies 52 with elastic self-restoring force and Fixedly arranged on the pick-up head 51, the undeformed initial state of the multiple claws of the jaws is an outwardly expanding structure in the shape of a "eight". In this embodiment, the material of the elastic body 52 is polyurethane, and the friction The part is through the eight through holes 131 provided on the lower panel 13. The pick-up head 51 of the pick-up assembly is arranged in the body and corresponding to the positions of the through holes 131 and placed in the through holes 131. Its claws 52 Extend through the through hole 131 to the outside of t...

Embodiment 2

[0047] The structure of the material retrieving device provided in this embodiment is roughly the same as that of Embodiment 1. The only difference is that in this embodiment, the claws of the claws are inelastic and straight structures, and the claws are all pivotally connected to each other. On the pick-up head 51, the elastic force of the elastic parts (such as springs or shrapnel, etc.) between the multiple claws makes it expand outward. During the lifting process of the claws, the multiple claws are connected The compression of the conflicting through-holes further compresses the elastic member to achieve inward retraction, and the elastic force of the elastic member causes the plurality of claws of the claw to recover and expand outward during the lowering process of the claw. And then realize the retrieving.

[0048] The disclosed elastic parts and connection relationships added in this embodiment are all prior art, which can be easily grasped and implemented by those s...

Embodiment 3

[0050] A kind of material retrieving device provided in this embodiment, its structure is roughly the same as that of Embodiment 1, the only difference is that, refer to Figure 7 As shown, in this embodiment, the interference part is a ring-shaped member 70 arranged on the periphery of the claw portion 52 of the claw. The ring-shaped member 70 is connected to the driving end of the lifting mechanism, and the lifting mechanism drives the ring-shaped member 70 and the claw. Move to do relative movement, such as: the lifting mechanism drives the ring 70 to descend, and the lifting mechanism drives the claws to rise. At this time, the ring 70 is in contact with the claw portion 52 of the claw, and makes multiple claws of the claw The part 52 is in a converging structure, and then the lifting mechanism drives the ring part 70 to rise, and the lifting mechanism drives the jaws down. At this time, the claw part 52 of the jaw breaks away from the ring part 70, and the elastic self-res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com