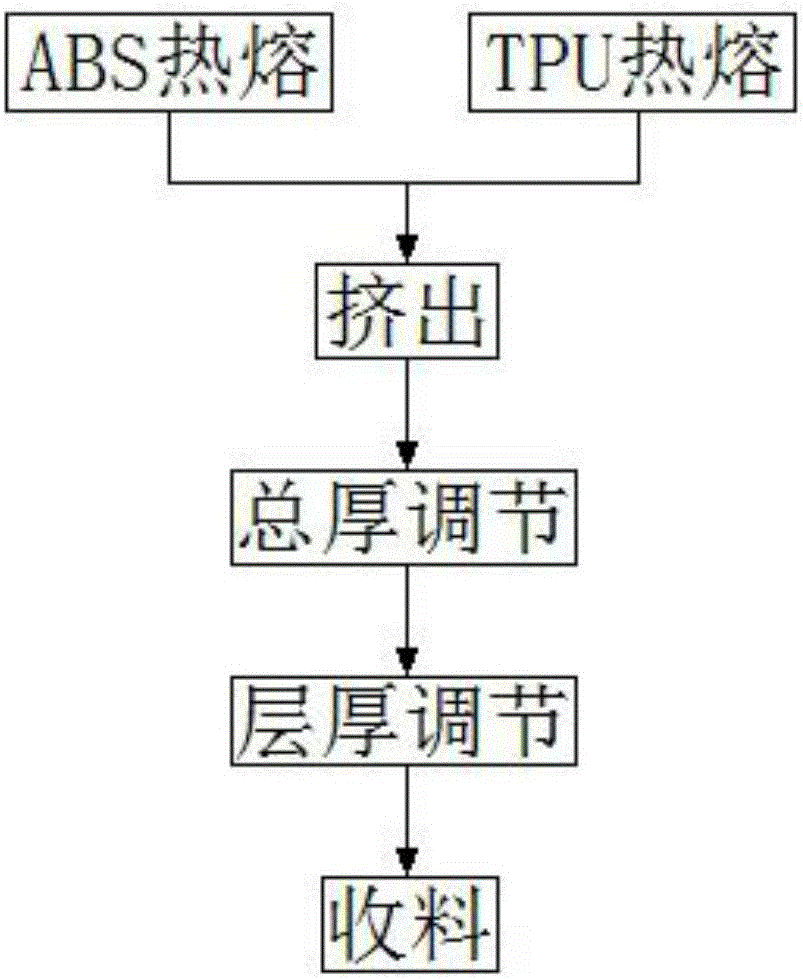

TPU-ABS composite board co-extrusion technology

A composite board and process technology, which is applied in the field of TPU-ABS composite board co-extrusion technology, can solve the problems of increased fluidity of TPU, achieve strong interlayer bonding, high processing efficiency, and prevent poor processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in further detail below in conjunction with specific embodiments.

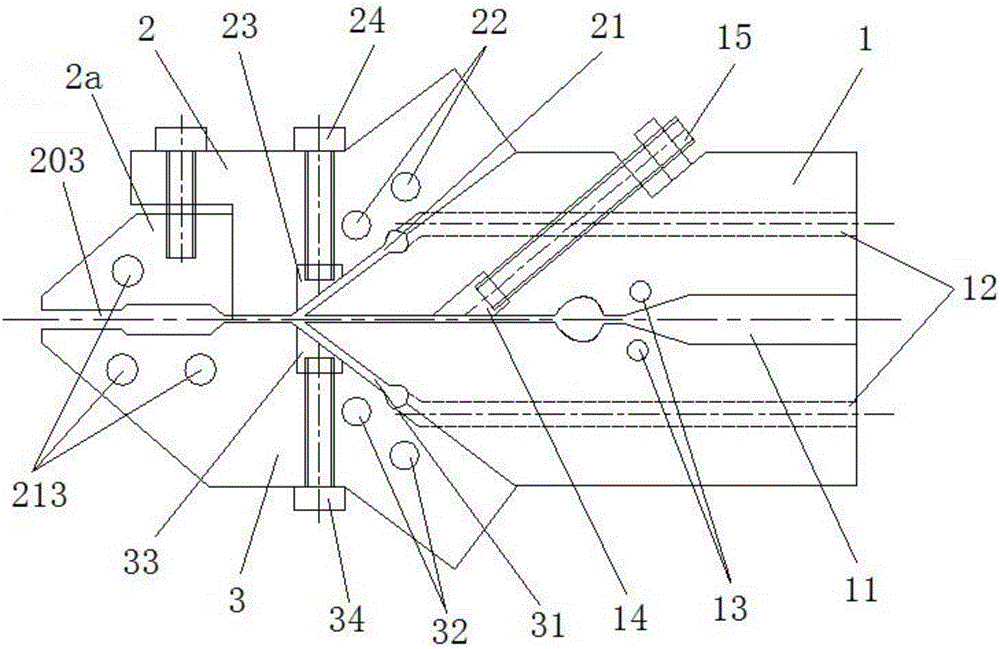

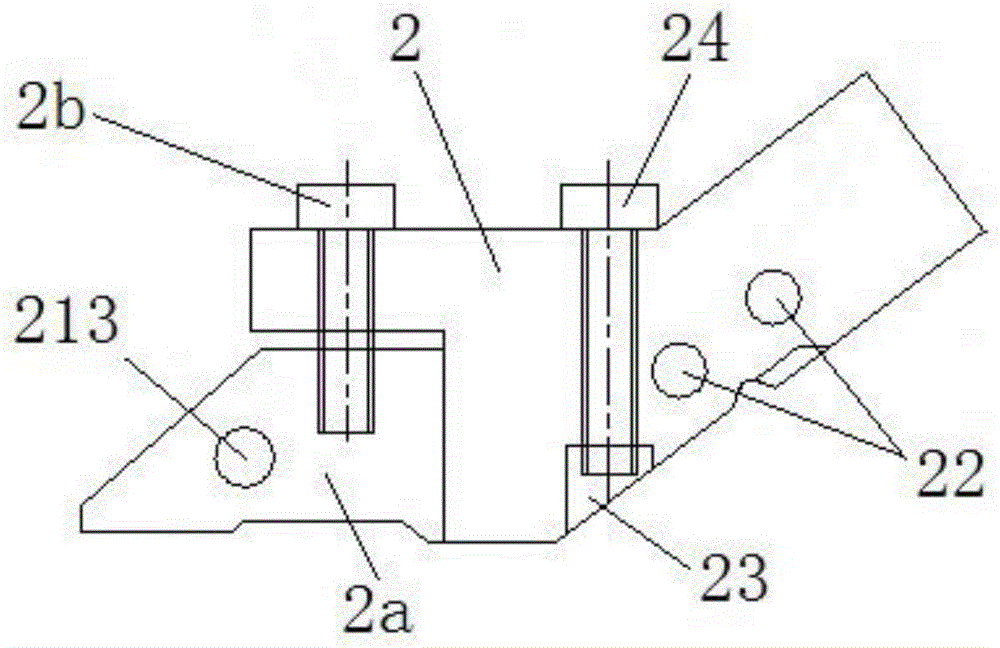

[0049] Such as figure 1 and image 3 Shown, a kind of TPU-ABS composite plate co-extrusion mold of the present invention comprises first mold body 1, second mold body 2 and the 3rd mold body 3, and first mold body 1 has an inner runner 11 and two Side runner 12, the inner runner 11 extends to the front edge of the first mold body 1 and forms a flat inner flow slit (not marked), extending from the outlet of the inner runner 11 to both sides for installing the second mold body 2 respectively and the two slopes of the third mold body 3, the second mold body 2 and the third mold body 3 are separated to form a flat extrusion slit 203; the interface between the second mold body 2 and the first mold body 1 is provided with an external The closed first side flow slot 21, the first side flow slot 21 communicates with the side flow channel 12; the interface between the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com