Preparation method of mullite spherical aggregate reinforced refractory material

A technology of refractory material and mullite, applied in the field of refractory material, can solve the problems of non-compliance of size, waste, increase of manufacturing cost, etc., and achieve the effect of being conducive to close packing, low manufacturing cost and improving performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

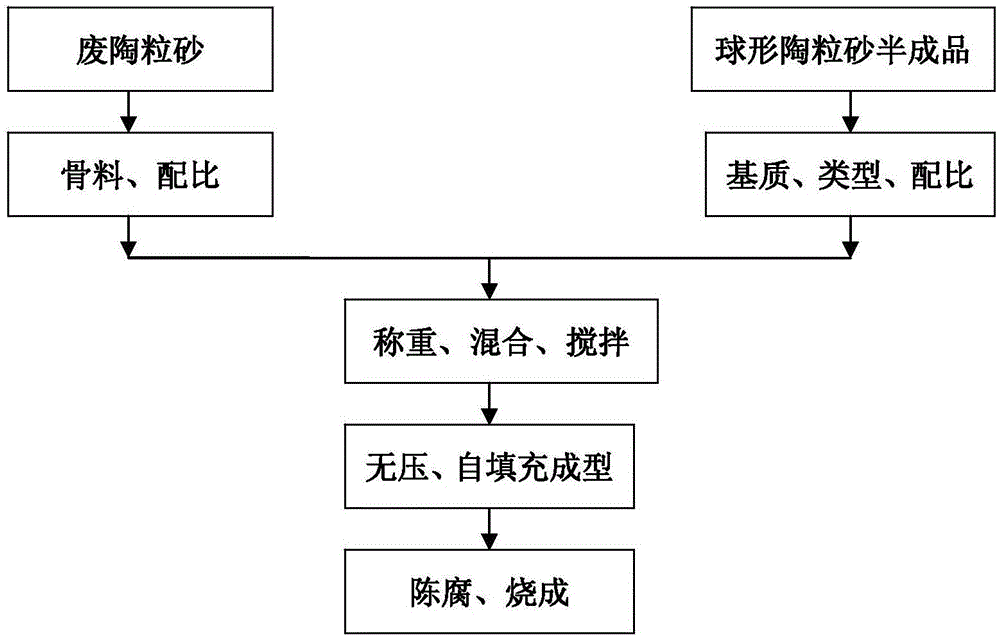

Method used

Image

Examples

Embodiment 1

[0054] (1) Raw material composition

[0055] Proportioning (parts by weight): 70 parts of waste ceramsite sand (aggregate), 30 parts of spherical ceramsite sand semi-finished products (matrix);

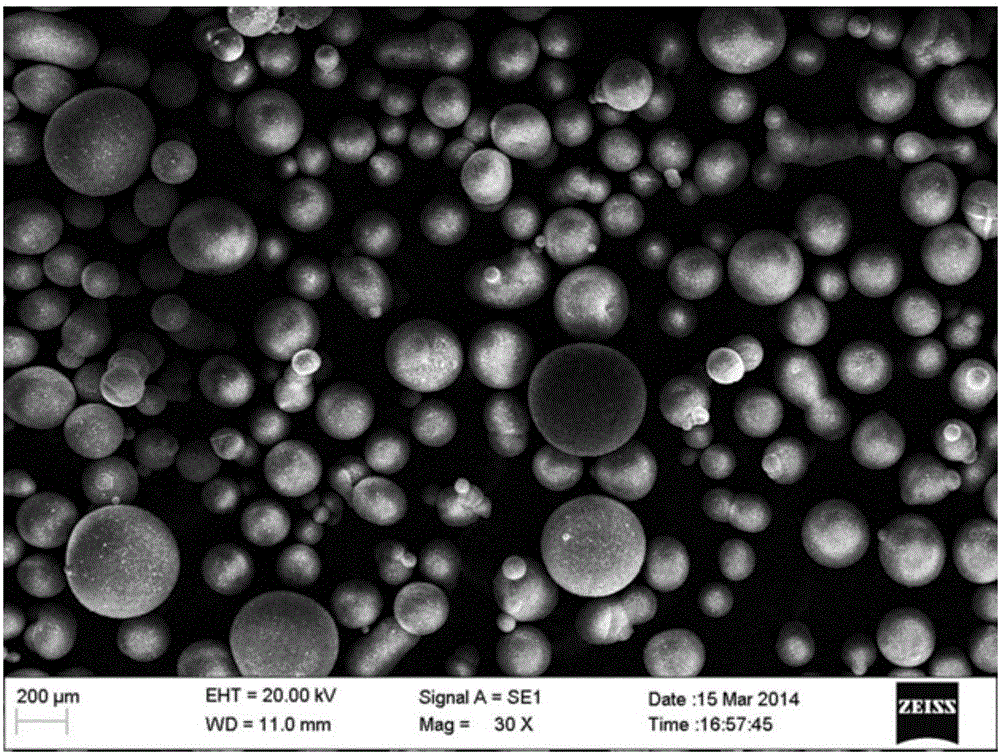

[0056] Wherein the composition of waste ceramsite sand is (weight ratio): account for 40% on the 20 mesh sieve, and account for 60% under the 140 mesh sieve;

[0057] Spherical ceramsite sand semi-finished products are added in coarse type, and its specific size distribution is (weight ratio): 10-60 mesh accounts for 60%, 60-120 mesh accounts for 30%, and 120 mesh or more accounts for 10%.

[0058] (2) Collect the waste ceramsite sand according to the mesh number required in step (1) for use, and match according to the ratio;

[0059] (3) In the semi-finished product stage of ceramsite sand production, the spherical semi-finished product is collected through a double-layer swinging sieve to collect the mesh number required by step (1) for use, and the spherical semi-finished product ...

Embodiment 2

[0066] (1) Raw material composition

[0067] Proportioning (parts by weight): 65 parts of waste ceramsite sand (aggregate), 35 parts of spherical ceramsite sand semi-finished products (matrix),

[0068] Wherein the composition of waste ceramsite sand is (weight ratio): wherein on the 20 mesh sieve accounts for 50%, and under the 140 mesh sieve accounts for 50%;

[0069] Among them, the spherical ceramsite sand semi-finished product is added in the middle class, and its specific size distribution is (weight ratio): 10-60 mesh accounts for 30%, 60-120 mesh accounts for 40%, and 120 mesh or more accounts for 30%;

[0070] (2) Collect the waste ceramsite sand according to the mesh number required in step (1) for use, and match according to the ratio;

[0071] (3) In the semi-finished product stage of ceramsite sand production, the spherical semi-finished product is passed through a double-layer swinging sieve to collect the mesh number required in step (1) for use, and the spheri...

Embodiment 3

[0078] (1) Raw material composition

[0079] Proportioning (parts by weight): 70 parts of waste ceramsite sand (aggregate), 30 parts of spherical ceramsite sand semi-finished products (matrix);

[0080] The composition of described waste ceramsite sand is (weight ratio): account for 60% on the 20 mesh sieve, account for 40% under the 140 mesh sieve;

[0081] Spherical ceramsite sand semi-finished products are added by fine class, and its specific size distribution is (weight ratio): 10-60 mesh accounts for 10%, 60-120 mesh accounts for 30%, and 120 mesh or more accounts for 60%;

[0082] (2) Collect the waste ceramsite sand according to the mesh number required in step (1) for use, and match according to the ratio;

[0083] (3) In the semi-finished product stage of ceramsite sand production, the spherical semi-finished product passes through the double-layer swinging sieve to collect the mesh number required in step (1) for use, and matches the spherical semi-finished product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com