Preparation method of mullite spherical aggregate reinforced refractory material

A technology of refractory material and mullite, applied in the field of refractory material, can solve the problems of increased manufacturing cost, unsatisfactory size, waste, etc., and achieves the effects of improving performance, being conducive to close stacking, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

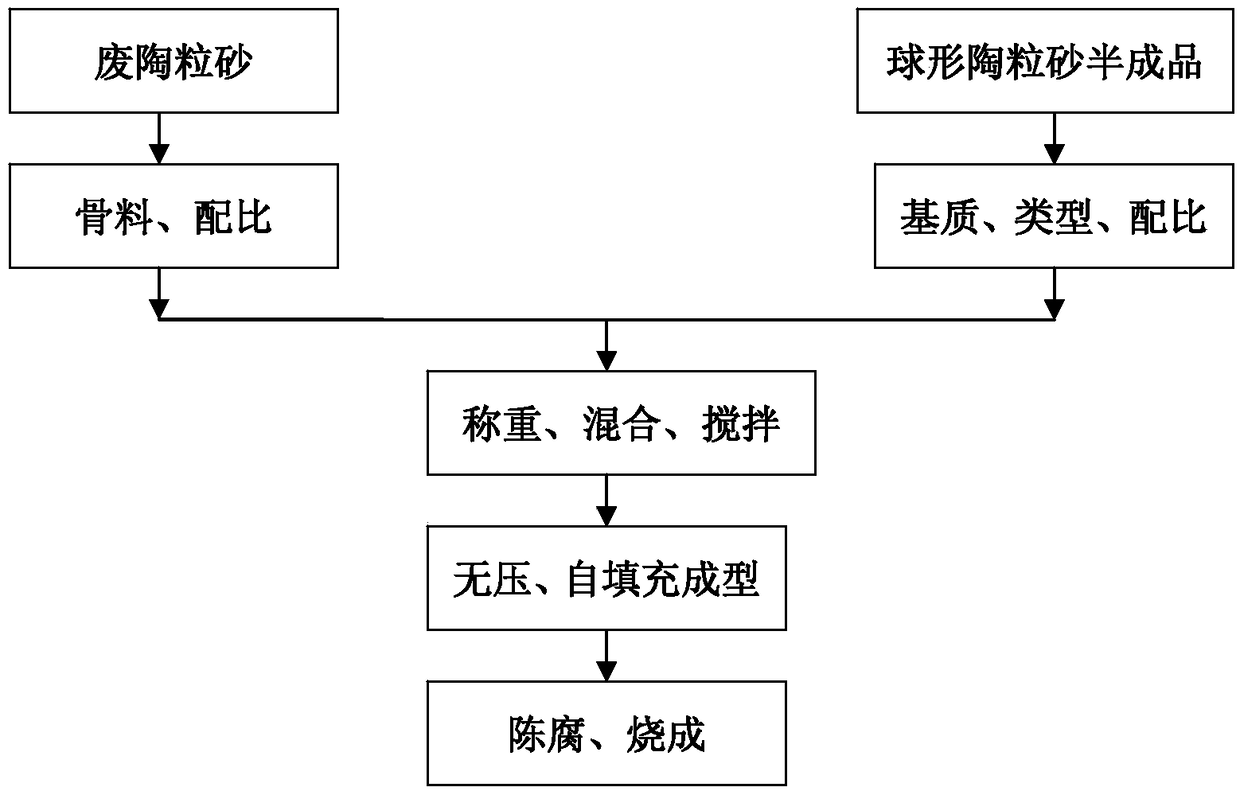

Method used

Image

Examples

Embodiment 1

[0054] (1) Raw material composition

[0055] Proportioning (parts by weight): 70 parts of waste ceramsite sand (aggregate), 30 parts of spherical ceramsite sand semi-finished products (matrix);

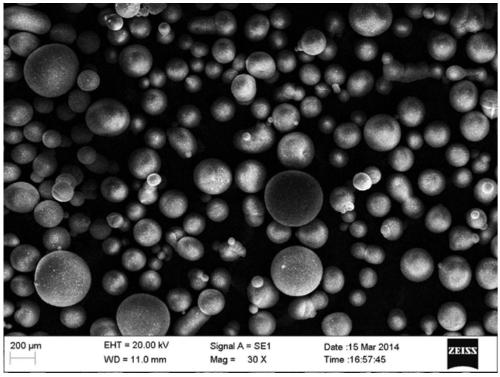

[0056] Wherein the composition of waste ceramsite sand is (weight ratio): account for 40% on the 20 mesh sieve, and account for 60% under the 140 mesh sieve;

[0057] Spherical ceramsite sand semi-finished products are added in coarse type, and its specific size distribution is (weight ratio): 10-60 mesh accounts for 60%, 60-120 mesh accounts for 30%, and 120 mesh or more accounts for 10%.

[0058] (2) Collect the waste ceramsite sand according to the mesh number required in step (1) for use, and match according to the ratio;

[0059] (3) In the semi-finished product stage of ceramsite sand production, the spherical semi-finished product is collected through a double-layer swinging sieve to collect the mesh number required by step (1) for use, and the spherical semi-finished product ...

Embodiment 2

[0066] (1) Raw material composition

[0067] Proportioning (parts by weight): 65 parts of waste ceramsite sand (aggregate), 35 parts of spherical ceramsite sand semi-finished products (matrix),

[0068] Wherein the composition of waste ceramsite sand is (weight ratio): wherein on the 20 mesh sieve accounts for 50%, and under the 140 mesh sieve accounts for 50%;

[0069] Among them, the spherical ceramsite sand semi-finished product is added in the middle class, and its specific size distribution is (weight ratio): 10-60 mesh accounts for 30%, 60-120 mesh accounts for 40%, and 120 mesh or more accounts for 30%;

[0070] (2) Collect the waste ceramsite sand according to the mesh number required in step (1) for use, and match according to the ratio;

[0071] (3) In the semi-finished product stage of ceramsite sand production, the spherical semi-finished product is passed through a double-layer swinging sieve to collect the mesh number required in step (1) for use, and the spheri...

Embodiment 3

[0078] (1) Raw material composition

[0079] Proportioning (parts by weight): 70 parts of waste ceramsite sand (aggregate), 30 parts of spherical ceramsite sand semi-finished products (matrix);

[0080] The composition of described waste ceramsite sand is (weight ratio): account for 60% on the 20 mesh sieve, account for 40% under the 140 mesh sieve;

[0081] Spherical ceramsite sand semi-finished products are added by fine class, and its specific size distribution is (weight ratio): 10-60 mesh accounts for 10%, 60-120 mesh accounts for 30%, and 120 mesh or more accounts for 60%;

[0082] (2) Collect the waste ceramsite sand according to the mesh number required in step (1) for use, and match according to the ratio;

[0083] (3) In the semi-finished product stage of ceramsite sand production, the spherical semi-finished product passes through the double-layer swinging sieve to collect the mesh number required in step (1) for use, and matches the spherical semi-finished product...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com