Nozzle block, pneumatic spinning device, and spinning machine

A technology of open-end spinning and nozzle block, which is applied in spinning machine, open-end spinning machine, continuous winding spinning machine, etc., can solve the problem of high yarn tension and achieve the effect of suppressing high tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. In addition, in each figure, the same reference numerals are assigned to the same or corresponding parts, and overlapping descriptions will be omitted.

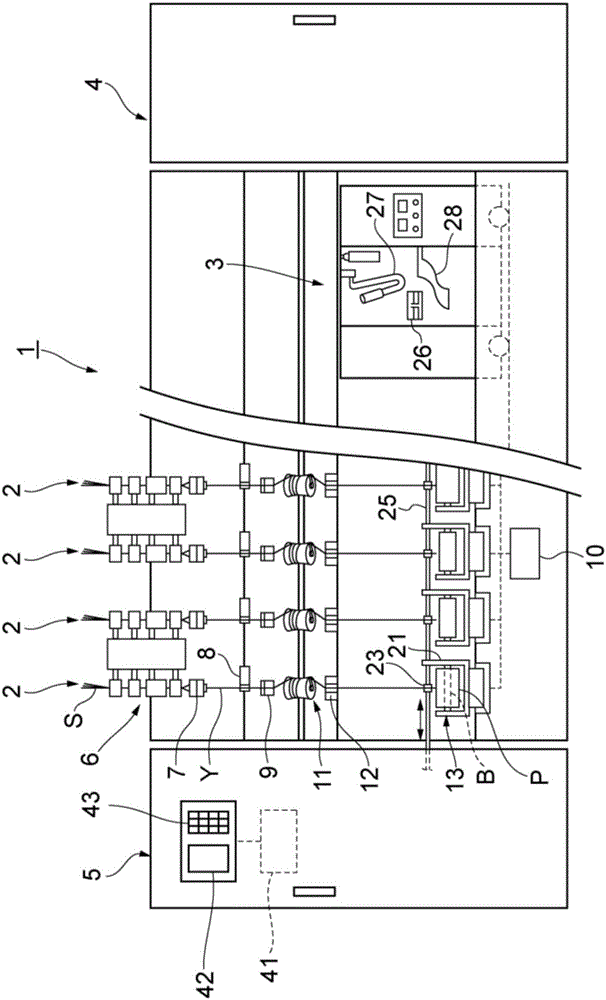

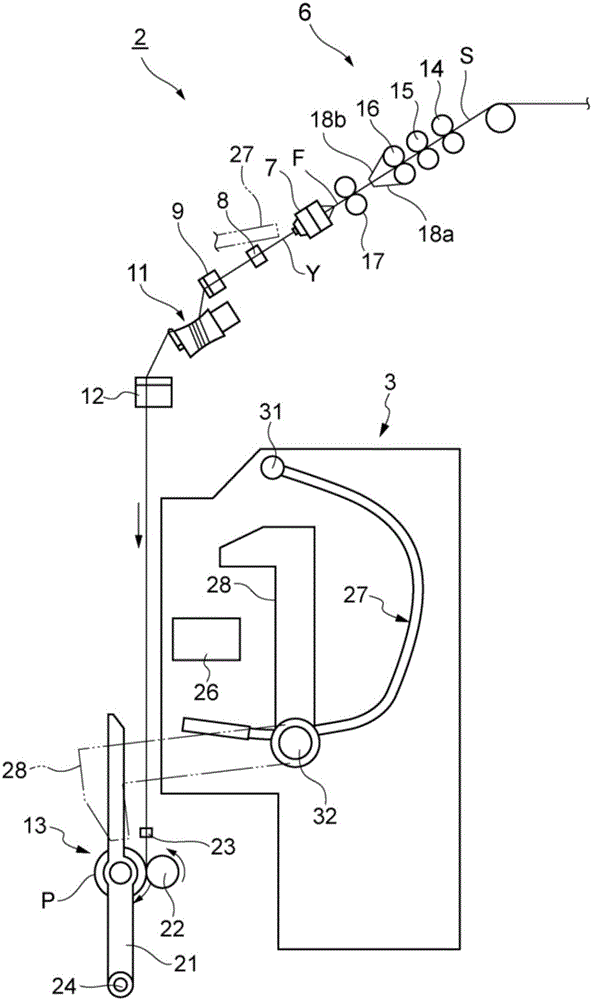

[0026] Such as figure 1 As shown, the spinning machine 1 includes a plurality of spinning units 2 , a yarn joining cart 3 , a doffing cart (not shown), a first end frame 4 , and a second end frame 5 . A plurality of spinning units 2 are arranged in a row. Each spinning unit 2 produces a yarn Y and winds it into a package P. The yarn joining cart 3 performs a yarn joining operation in a certain spinning unit 2 when the yarn Y is cut in the spinning unit 2 or the yarn Y is cut for some reason. The doffing trolley doffs the package P and supplies the new bobbin B to the spinning unit 2 when the package P in one of the spinning units 2 becomes full.

[0027] The first end frame 4 accommodates a recovery device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com