Slurry spraying device for lace cloth

A technology of spraying device and mud, which is applied in spraying device, spraying/jetting textile material processing and other directions, can solve the problems of wasting materials, inconvenient to take out, not suitable for large size, etc., and achieves the effect of saving mud, not easy to block holes, and moderate thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and preferred embodiment of the present invention, the present invention will be described in further detail, so that advantages and features of the present invention can be more easily understood by those skilled in the art

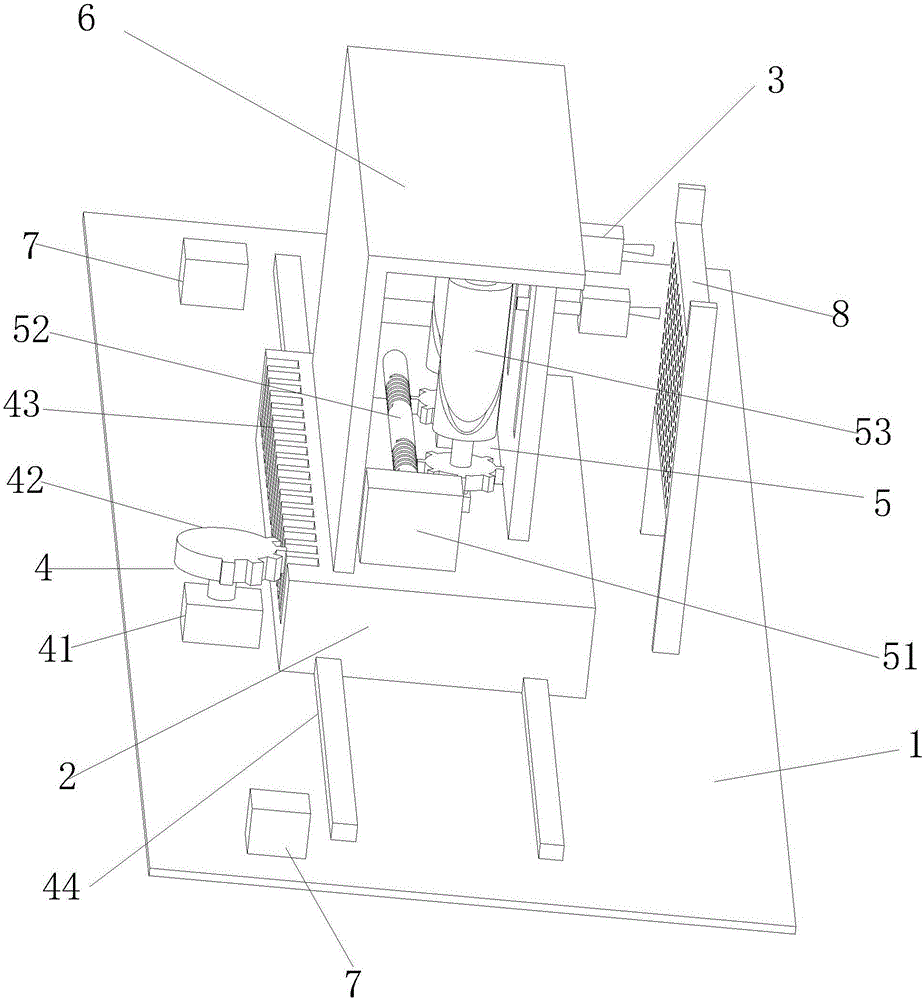

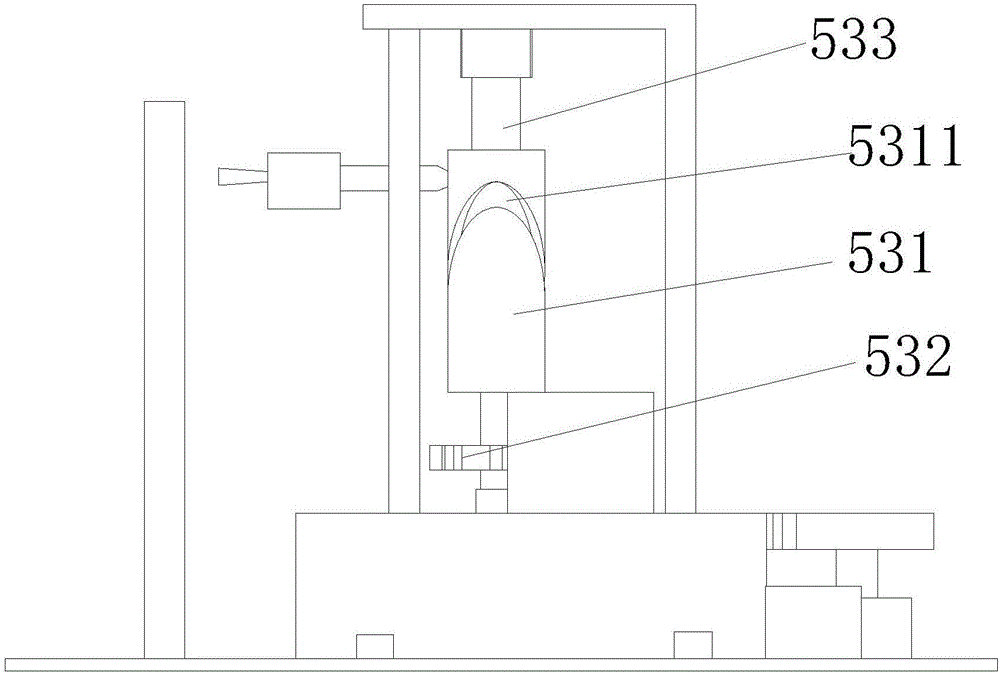

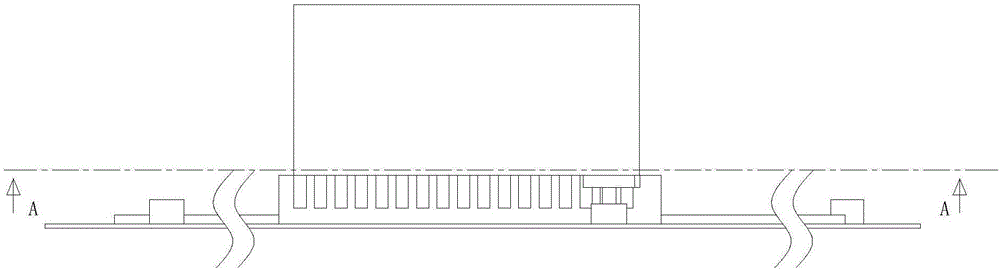

[0018] Such as figure 1 , 2 As shown, it includes a bottom plate (1), a spray gun (3), a slide table (2) is installed on the bottom plate (1), a spray gun movement mechanism (5) and a support plate (6) are installed on the slide table (2), and the spray gun Motion mechanism (5) comprises worm screw (52), cam mechanism (53), and worm screw (52) two ends are connected with motor one (51) and bearing seat one respectively, and described motor one (51), bearing seat one are installed on On the upper end surface of the slide table (2), the cam mechanism (53) includes a shaft (533), and the two ends of the shaft (533) are respectively connected to the support plate (6) and the slide table (2) through the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com