Papermaking slurry preparation method

A preparation method and slurry technology, which is applied in the field of papermaking, can solve the problems such as poor effect of final paper strength improvement, and achieve the effect of strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

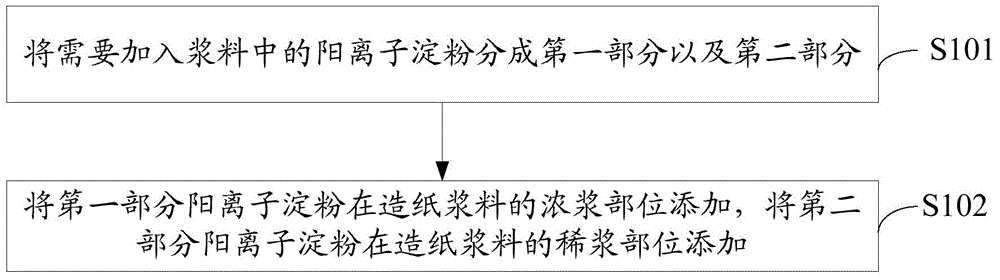

Method used

Image

Examples

Embodiment

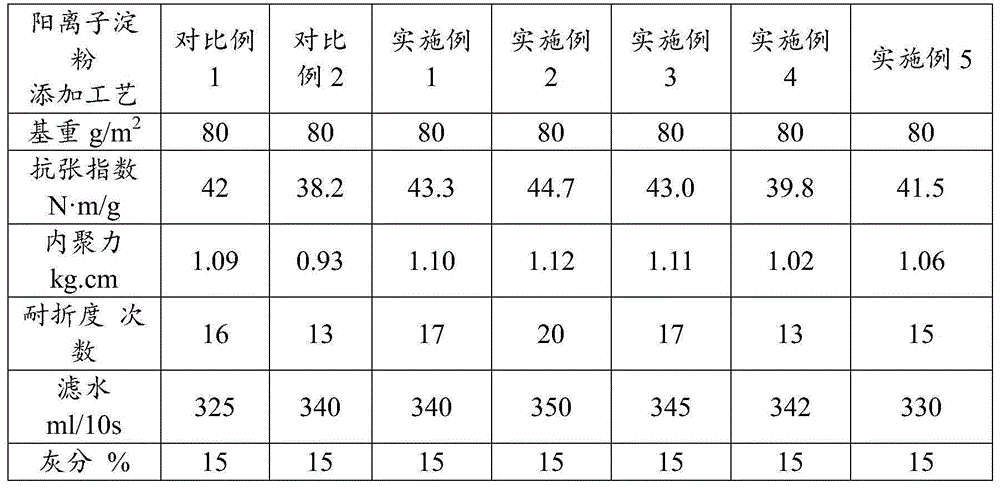

[0037] In the mixed pulp, there are 20% bleached softwood pulp, 70% bleached hardwood pulp and 10% chemical mechanical pulp.

[0038] The total amount of cationic starch added is 8kg (absolute-dry starch) / ton of paper, and the amount of cationic starch in the first part (added to the thick stock part) is set as a, and the amount of cationic starch in the second part (added to the thin stock part) is set as b;

[0039] In embodiment 1, a=7kg (absolute dry starch) / ton of paper, b=1kg (absolute dry starch) / ton of paper;

[0040] In embodiment 2, a=4kg (absolute dry starch) / ton of paper, b=4kg (absolute dry starch) / ton of paper;

[0041] In embodiment 3, a=6kg (absolute dry starch) / ton of paper, b=2kg (absolute dry starch) / ton of paper;

[0042] In embodiment 4, a=1kg (absolute dry starch) / ton of paper, b=7kg (absolute dry starch) / ton of paper;

[0043] In Example 5, a=7.5kg (absolute dry starch) / ton of paper, b=0.5kg (absolute dry starch) / ton of paper;

[0044] In comparative ...

Embodiment 4

[0049] In Example 4, a=1kg (absolute-dry starch) / ton of paper, b=7kg (absolute-dry starch) / ton of paper, a≤b, the water drainage performance is mainly improved, and the improvement of paper strength is not obvious.

[0050] In Example 5, b=0.5kg (absolute-dry starch) / ton of paper, b≤1kg (absolute-dry starch) / ton of paper, which mainly shows that the strength of the paper is improved, and the drainage performance of the pulp is not significantly improved.

[0051] The above detailed description of the specific embodiments of the present invention can be understood that in the present invention, the cationic starch addition process of the papermaking process has been improved, and cationic starch is added simultaneously in thick stock and thin stock, but the total amount of cationic starch has not been improved. the added amount. In the new addition process, the cationic starch added to the thick stock and thin stock has a synergistic effect, which improves the strength of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com