Large-radius chamfered sleeper for ballastless track concrete crack control and its construction method

A technology of ballastless track and large radius, which is applied in the direction of track, track laying, track maintenance, etc., can solve the problems of the overall ballast bed bearing capacity and durability decline, the overall ballast bed dismantling and rework, and the overall ballast bed slab cracking, etc., to achieve The effect of reducing the probability of development, significant economic benefits, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

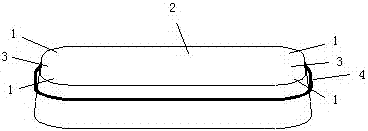

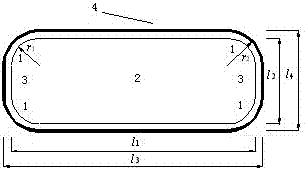

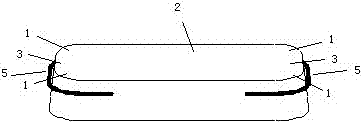

[0022] The present invention is a large-radius chamfered sleeper for controlling cracks in ballastless track concrete. For the corner of the sleeper structure, the chamfered part 1 of the sleeper with large-radius chamfer is used, and the chamfered part is equivalent to a quarter of a circular platform; The slope of the side of the corner part is consistent with the slope of the side of the part 3 between the middle section 2 of the sleeper structure and the chamfer of the end of the sleeper; the first anti-cracking reinforcement 4 or the second anti-cracking reinforcement 5 is arranged on the outer side of the sleeper; the first anti-cracking reinforcement 4 Arranged in a closed ring along the outer side of the sleeper, the second anti-cracking reinforcement 5 is only arranged in a ring within the predetermined range of the end of the sleeper and the middle section 2 of the sleeper structure connected to it; a protective layer 6 is provided on the top of the anti-cracking reinf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com