Seal coat spreading facility and spreading method

A spraying and equipment technology, applied in roads, road repairs, roads, etc., can solve the problems of complex process, poor vehicle versatility, high cost, etc., and achieve the effect of uniform spraying, easy maintenance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

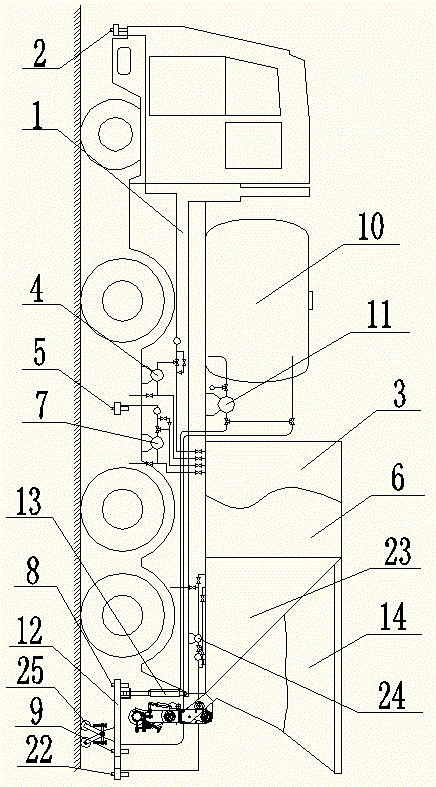

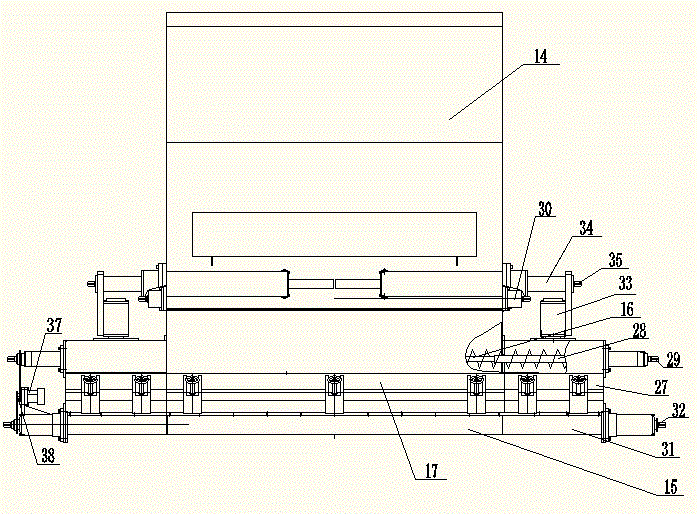

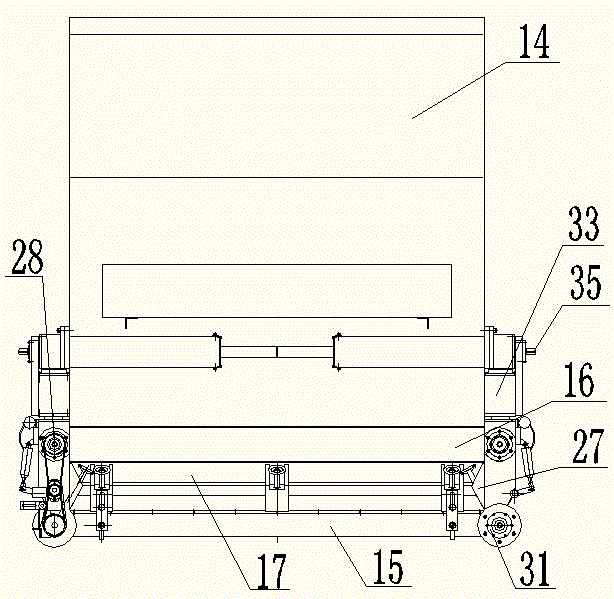

[0035] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment comprises car body 1, and car body 1 front end is equipped with water spraying device, and car body 1 middle part is installed with interface agent spraying device, and car body 1 rear part is installed with asphalt spraying device and stone spreading device, and asphalt spraying device includes front and back two There are three spraying parts, the stone spreading device is located between the two spraying parts before and after the asphalt spraying device, and the protective agent spraying device is installed at the tail end of the car body 1. The water spraying device includes a water spraying arm 2 arranged at the front end of the vehicle body 1 , the water spraying arm 2 is connected with a water tank 3 , and a water pump 4 is connected between the water spraying arm 2 and the water tank 3 . The interface agent spraying device includes an interface agent spraying arm 5 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com