Steam turbine sliding pressure optimization control method based on multi-dimension curved surface

An optimized control and steam turbine technology, which is applied in the direction of engine control, mechanical equipment, engine components, etc., can solve problems affecting the economy of the unit, and achieve the effect of avoiding unsafe effects and improving economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

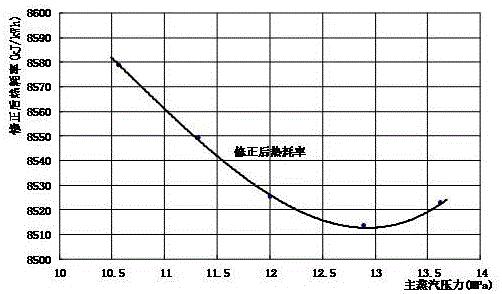

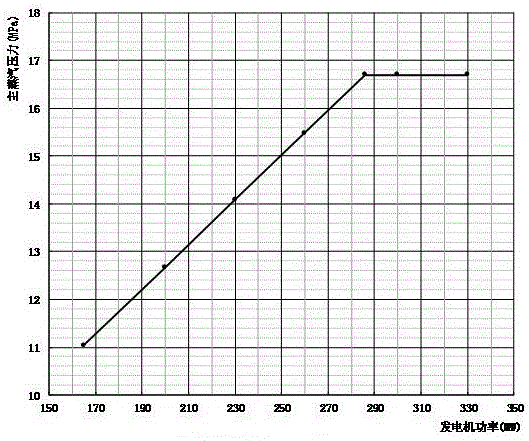

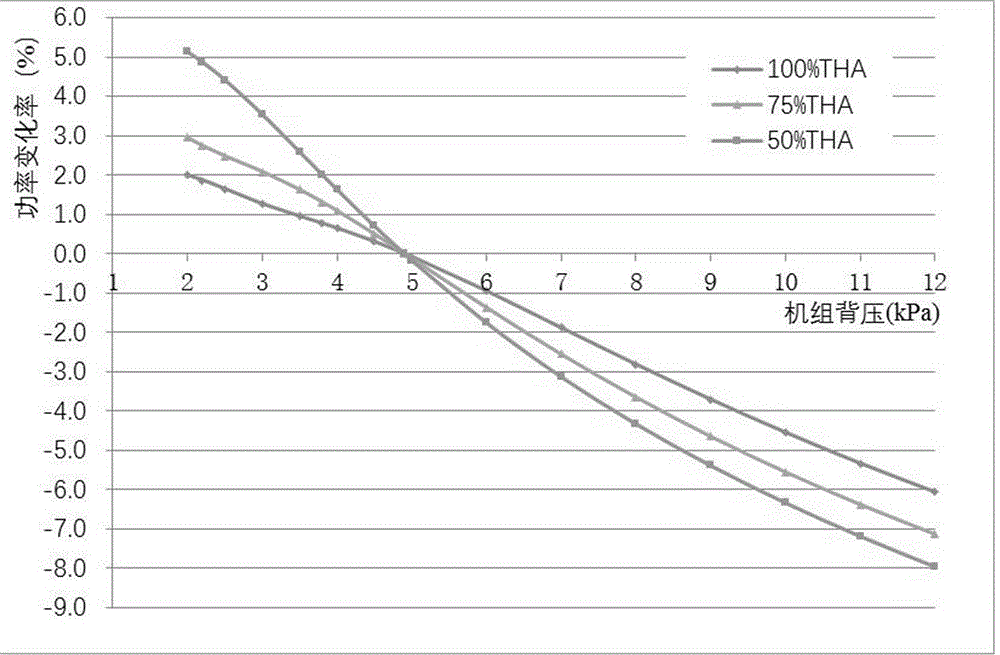

[0029] Such as Figure 1 to Figure 3 As shown, a steam turbine sliding pressure optimization control method based on multi-dimensional surfaces includes the following steps: 1) Select a number of conventional load points in the operating range of the load unit to conduct a comparative test on the thermal efficiency of the steam turbine and optimize the sliding pressure operation; 2) According to the unit back pressure correction curve, the sliding pressure data under different back pressures are obtained; 3) According to the data regression analysis, the sliding pressure control function is obtained; 4) The optimization result is realized in DCS, that is, the obtained multi-dimensional sliding pressure surface By making the function into the DCS of the unit, the optimal control of the sliding pressure of the steam turbine on the multi-dimensional surface can be realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com