Sulfur poisoning removal device of SCR catalyst of diesel engine and using method for sulfur positioning removal device

A technology of SCR catalyst and sulfur poisoning, applied in mufflers, exhaust devices, machines/engines, etc., can solve the problems of high degree of deterioration of engine fuel economy and low degree of deterioration of engine fuel economy, and achieve good desulfurization effect , Low fuel economy deterioration, good desulfurization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

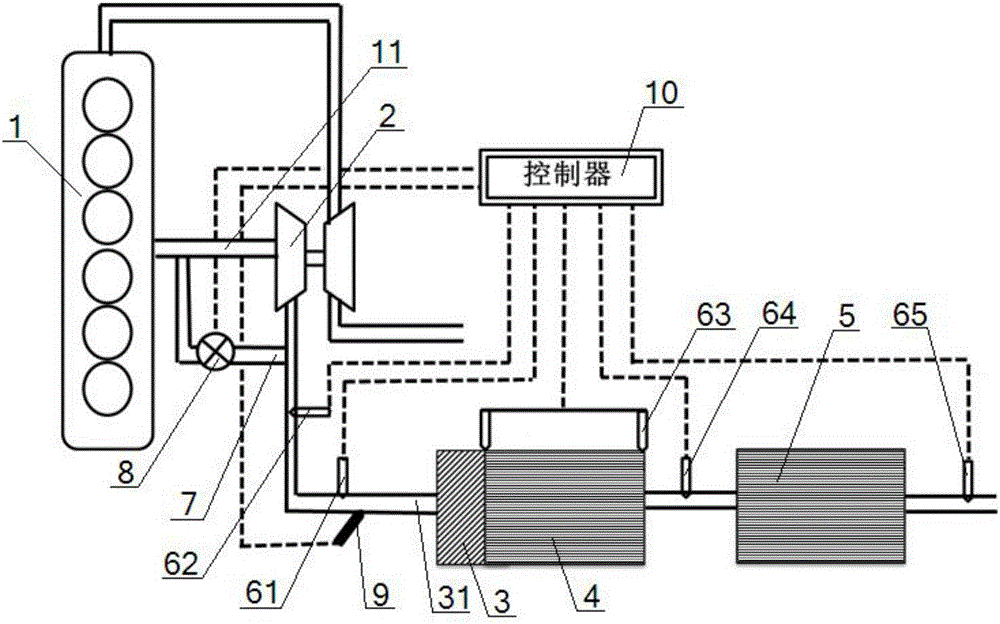

[0050] see Figure 1 to Figure 3 , a diesel engine SCR catalytic converter sulfur poisoning elimination device, including an engine 1, a turbocharger 2, an oxidation catalytic converter DOC3, a particle trap DPF4, an SCR catalytic converter 5, a bypass line 7, and a DPF regeneration fuel nozzle 9 , the intake end of the DOC3 communicates with the exhaust pipe 11 of the engine 1 through the intake pipeline 31 and the turbocharger 2 in turn, and the exhaust end of the DOC3 communicates with the SCR catalytic converter 5 through the DPF4, and the SCR catalytic converter 5 It is a copper-based zeolite-type SCR, and the inlet and exhaust ends of the bypass pipeline 7 communicate with the exhaust pipe 11 and the intake pipeline 31 respectively. The DPF regenerated fuel nozzle 9 and the No. 1 temperature sensor are arranged on the intake pipeline 31 61. No.1 NO X Sensor 62, pressure sensor 63 is provided at the intake and exhaust ends of DPF4, No. 2 temperature sensor 64 and No. 2 N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com